Polyurethane-acrylate cathodic electrophoretic coating material, preparation method therefor and application of polyurethane-acrylate cathodic electrophoretic coating material

A technology of polyurethane acrylate and cathodic electrophoretic coatings, which is applied in the direction of polyurea/polyurethane coatings, electrophoretic coatings, electrolytic coatings, etc., which can solve the problems of high baking temperature, low temperature baking resistance, and poor stability of coatings, and achieve paint film Fullness, good chemical resistance, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

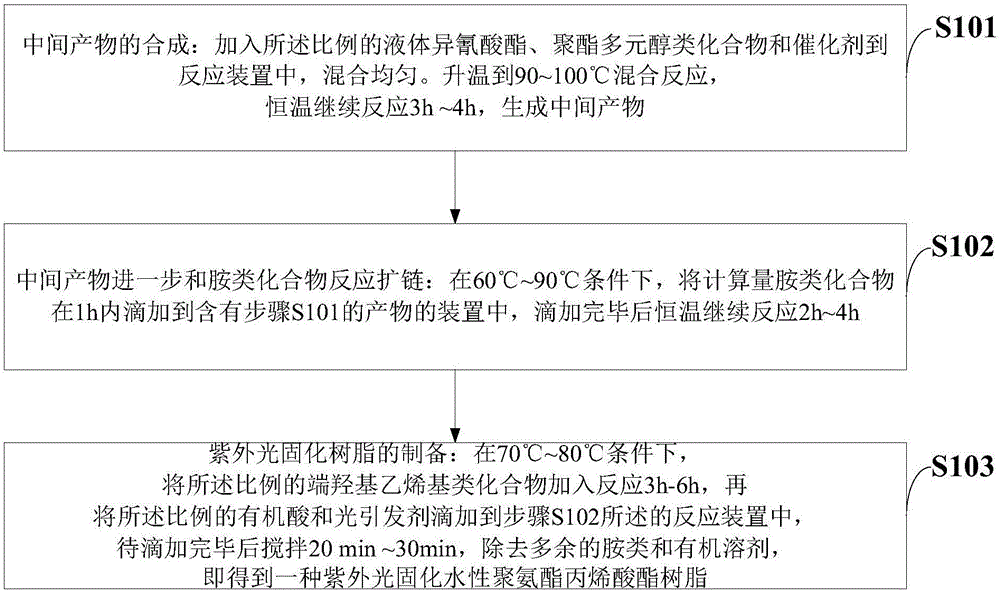

[0033] Such as figure 1 Shown, the preparation method of the polyurethane acrylate cathodic electrophoresis resin of the embodiment of the present invention comprises the following steps:

[0034] S101: Synthesis of intermediate products: Add the liquid isocyanate, polyester polyol compound and catalyst in the stated ratio into the reaction device, and mix evenly. Raise the temperature to 90-100°C for mixed reaction, and continue the reaction at constant temperature for 3h-4h to generate intermediate products;

[0035] S102: The intermediate product is further reacted with the amine compound to extend the chain: under the condition of 60°C-90°C, add the calculated amount of the amine compound dropwise to the device containing the product of step S101 within 1 hour, and continue the reaction at a constant temperature after the dropwise addition is completed 2h~4h;

[0036] S103: Preparation of UV curable resin: under the condition of 70°C to 80°C, add the stated proportion of...

Embodiment 1

[0045] Prepare raw materials according to the mass percentage of the total materials:

[0046] Component mass percentage (wt.%)

[0047] Isophorone diisocyanate (IPDI) 22%, N-methyldiethanolamine 8.2%, polycarbonate diol 22%, polycaprolactone diol 8%, polycaprolactone triol 3%, lactic acid 2.5% , organic bismuth catalyst (Bicat8118) 0.1%, propylene glycol methyl ether 9%, pentaerythritol triacrylate 12.7%, methacrylate-β-hydroxyethyl 8.5%, photoinitiator 4%, leveling agent 0.03%

[0048] In a reactor equipped with reflux, heating and stirring devices, add the polyisocyanate, polyester polyol compound and catalyst in said proportion into the reaction device, and mix evenly. Raise the temperature to 90°C-100°C for mixed reaction, continue the reaction at constant temperature for 3h-4h, and generate intermediate products; lower the temperature appropriately, and add the calculated amount of amine compounds dropwise to the device containing the intermediate product within 1h unde...

Embodiment 2

[0056] Prepare raw materials according to the mass percentage of the total material: component mass percentage (wt.%)

[0057] Diethanolamine 1%, N,N-dimethylethanolamine 2%, N-methyldiethanolamine 2%, isophorone diisocyanate (IPDI) 11%, polyethylene glycol oxalate diol 13%, Polycaprolactone triol 7%, glacial acetic acid 3.9%, triphenylphosphine 0.6%, ethylene glycol methyl ether 8%, acetone 25%, pentaerythritol triacrylate 10%, methacrylate-β-hydroxyethyl ester 8.5% %, hydroxyethyl methacrylate phosphate 4%, photoinitiator 4%, leveling agent 0.03%

[0058] In a reactor equipped with reflux, heating and stirring devices, add the polyisocyanate, polyester polyol compound and catalyst in said proportion into the reaction device, and mix evenly. Raise the temperature to 90°C-100°C for mixed reaction, continue the reaction at constant temperature for 3h-4h, and generate intermediate products; lower the temperature appropriately, and add the calculated amount of amine compounds dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

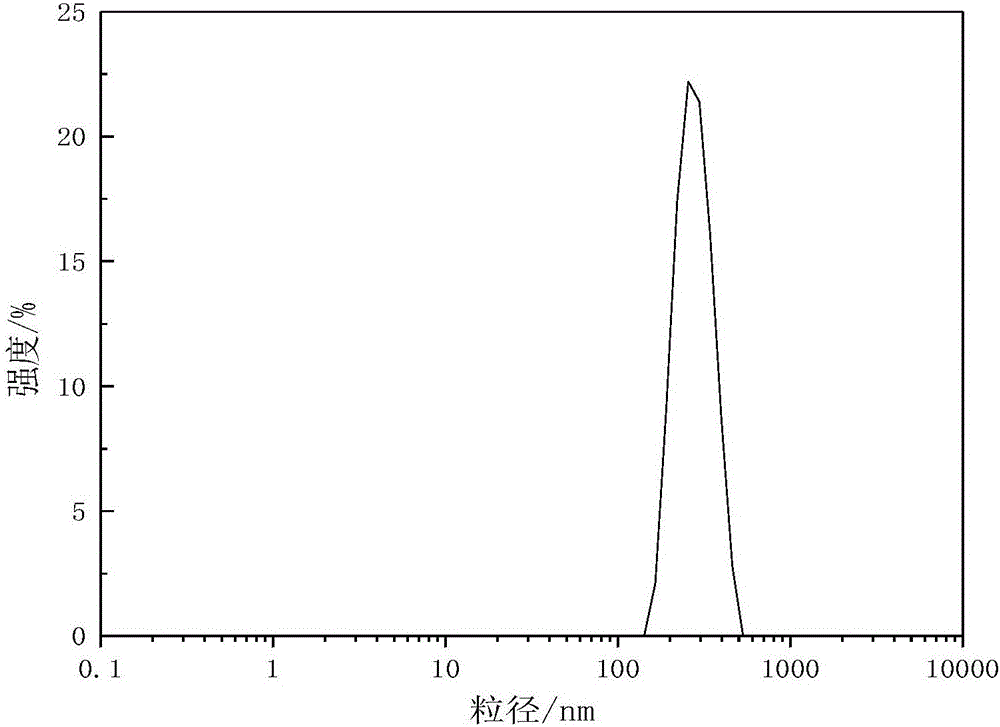

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com