Compound anti-microbial master batch and preparation method thereof, anti-microbial plastic packaging product and preparation method thereof

A technology of compounding antibacterial and antibacterial plastics, applied in the field of functional plastics, can solve the problems of uneven dispersion of antibacterial agents, microphase migration, microphase separation, etc., and achieve the effect of improving antibacterial efficiency and broad spectrum, and solving poor compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

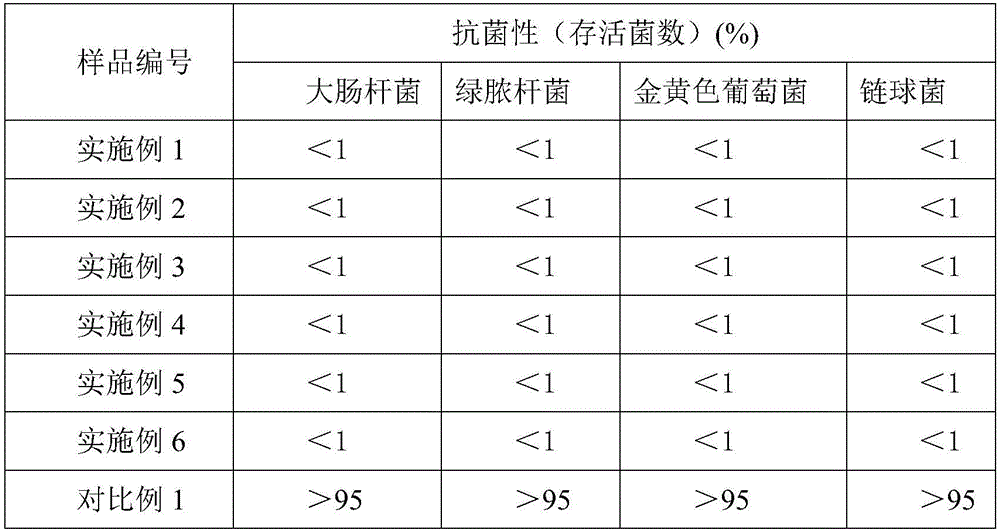

Examples

Embodiment 1

[0030] The embodiment of the present invention a kind of preparation method of compound antibacterial masterbatch, comprises the following steps:

[0031] (1) Preparation steps of inorganic antibacterial agent: AgNO 3 (Ionic antibacterial agent) is dispersed and suspended in calcium phosphate solution (carrier solution), after ion exchange reaction, after filtering and drying, the obtained substance is mixed with Ag 2 O are stirred evenly together, add bentonite (binder), calcined at 800°C for 1h, grind, and pass through a 325 mesh sieve to obtain an inorganic antibacterial agent;

[0032] (2) The preparation step of organic-inorganic composite antibacterial agent: the inorganic antibacterial agent that step (1) obtains is made into suspension, adds benzyl ammonium chloride salt (antibacterial dispersant), allyltriethylammonium bromide ( organic antibacterial agent) and azobisisoheptanonitrile (thermal initiator), reacted at 75°C for 20h, filtered, washed with water, dried in...

Embodiment 2

[0041] The embodiment of the present invention a kind of preparation method of compound antibacterial masterbatch, comprises the following steps:

[0042] (1) The preparation step of inorganic antibacterial agent: the neodymium oxide Nd2 o 3 (Ionic antibacterial agent) dispersed and suspended in sodium-based montmorillonite (Na-MMT) solution, after ion exchange reaction, stirred at 65°C for 4 hours, filtered, washed, vacuum-dried at 65°C for 48 hours, ground, passed through a 325-mesh sieve, Get neodymium-montmorillonite (Nd-MMT), which is the inorganic antibacterial agent;

[0043] (2) The preparation step of organic-inorganic composite antibacterial agent: the inorganic antibacterial agent that step (1) obtains is made into suspension, adds alkyltrimethylammonium salt (antibacterial dispersant), 6-bromohexanoic acid-2- (2-methacryloyloxy) ethyl ester pyridinium salt (organic antibacterial agent) and Fe 2+ -Potassium persulfate (thermal initiator), reacted at 75°C for 20h, ...

Embodiment 3

[0052] The embodiment of the present invention a kind of preparation method of compound antibacterial masterbatch, comprises the following steps:

[0053] (1) Preparation steps of inorganic antibacterial agent: preheat 30ml of water glass and 50ml of sodium bicarbonate and pour them into a beaker at the same time, stir at a constant temperature of 90°C for 1h, add preheated 20ml of water glass and 25ml of sodium bicarbonate (add dropwise ), after reacting for 20min, the pH value was adjusted to be 5-6 to obtain a silica gel solution (carrier solution). In this silica gel solution, an ionic antibacterial agent composed of cerium nitrate and copper sulfate was added, suction filtered for 5 hours, washed with water, and the filter cake was placed in an oven. Drying at 120°C for 2 hours, grinding, and passing through a 325-mesh sieve to obtain copper-cerium antibacterial white carbon black, which is the inorganic antibacterial agent;

[0054] (2) The preparation step of organic-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com