Preparation method of water-based polyethersulfone dispersion

A technology of polyethersulfone and dispersion liquid is applied in the field of preparation of water-based polyethersulfone dispersion liquid. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

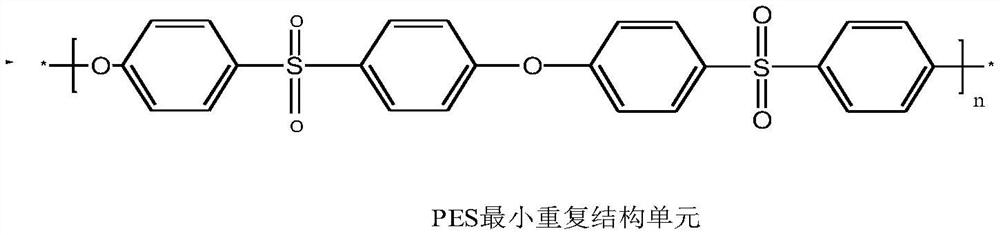

[0031] The preparation method of water-based polyethersulfone dispersion is prepared according to the following steps,

[0032] (1) Mix polyethersulfone and organic solvent at a mass ratio of 1:4-5, stir at 50-70°C for 4-6 hours to obtain polyethersulfone suspension; this step makes polyethersulfone swell in organic solvent Stirring at this temperature can speed up the dissolution of polyethersulfone; the organic solvent is a low-boiling organic solvent, which can be easily recovered without forming an azeotrope during distillation.

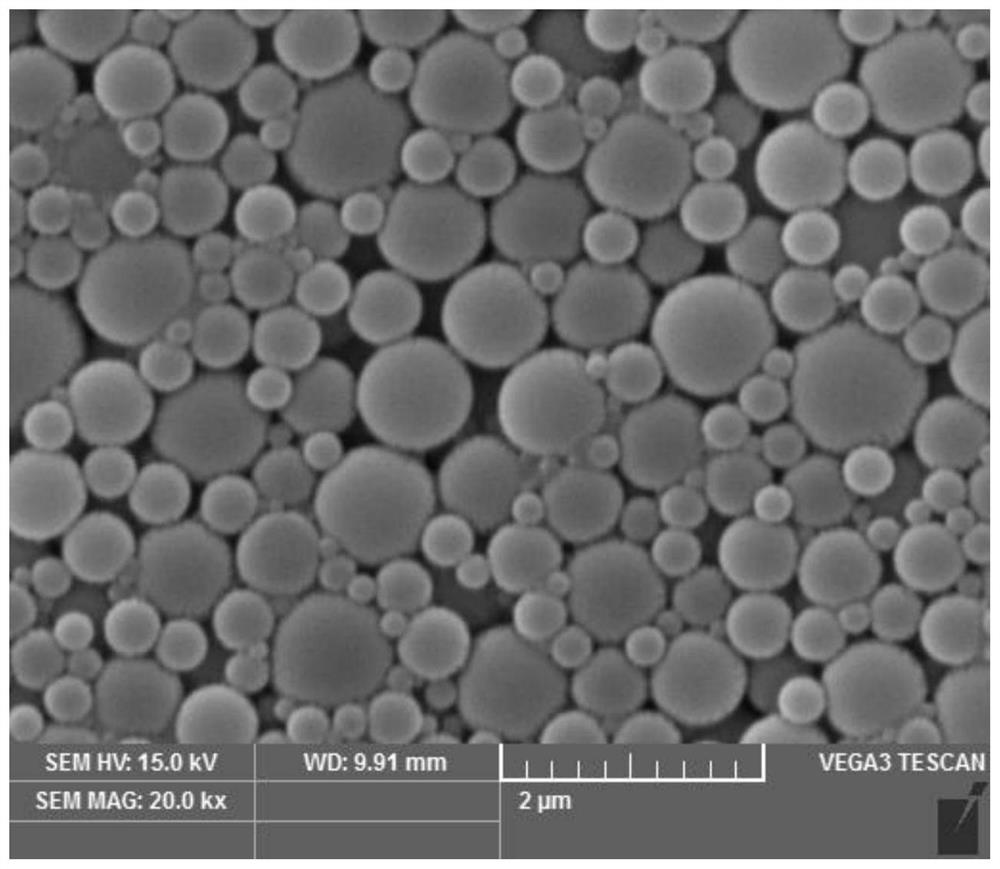

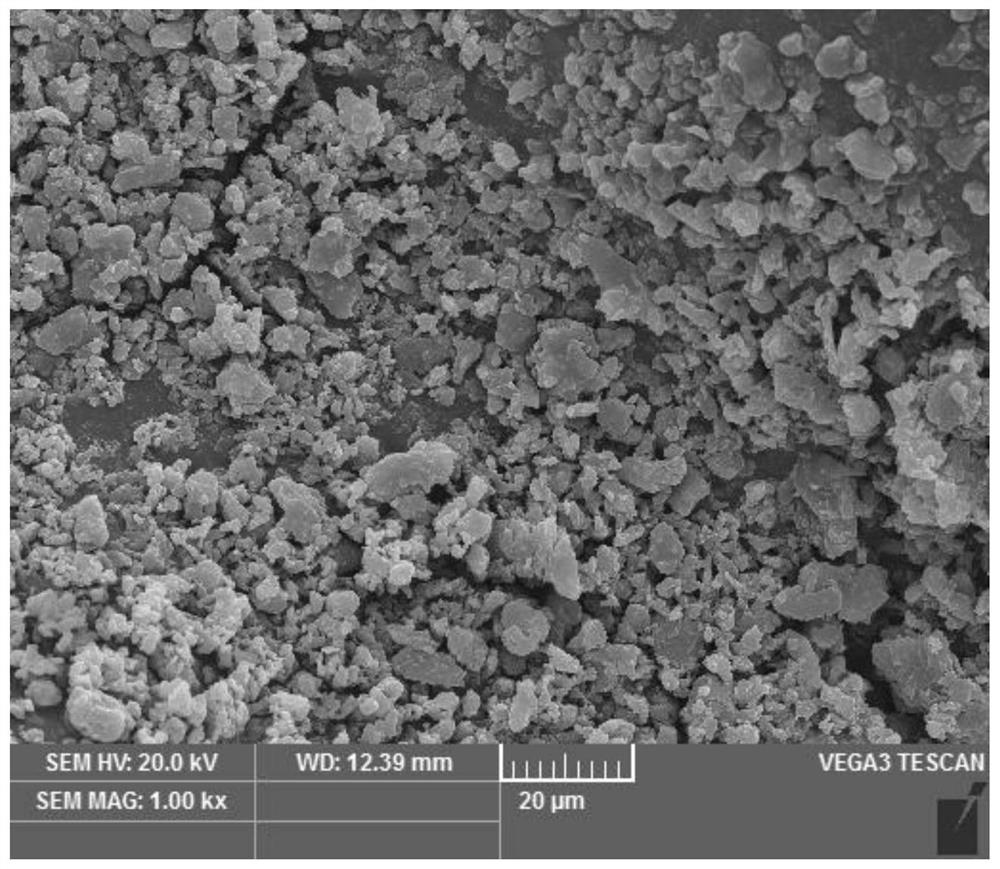

[0033] (2) After cooling the polyethersulfone suspension, disperse for 4 to 8 minutes, add the sedimentation liquid according to the mass ratio of polyethersulfone and sedimentation liquid at 1:5 to 7, and continue to disperse for 20 to 30 minutes to obtain a white mixed slurry; Described precipitation liquid is the liquid that organic solvent and deionized water are mixed by mass ratio 1:2~3;

[0034] (3) distilling the white mixed slurry to ob...

Embodiment 1

[0046] The preparation of embodiment 1 water-based polyethersulfone dispersion (method of the present invention)

[0047] Taking a 100L reactor as an example, prepare raw materials according to the following quality: polyethersulfone resin (8Kg), chloroform (40Kg), precipitation solution (48Kg, of which chloroform accounts for 16Kg, and deionized water accounts for 32Kg).

[0048] Accurately weigh the above formula components respectively, add polyethersulfone resin (8Kg) and chloroform (40Kg) into a 100L reactor equipped with a water separator, agitator and heating device, start stirring, and heat the reactor to 60°C , a polyethersulfone suspension was obtained after stirring for 4 hours.

[0049] Then the temperature of the reaction kettle was lowered to normal temperature, and the polyethersulfone suspension was put into a colloid mill with a shearing and grinding function for forced dispersion. After adding the precipitation liquid, continue to stir for 25 minutes to obta...

Embodiment 2

[0051] The preparation of embodiment 2 water-based polyethersulfone dispersion (method of the present invention)

[0052] Taking a 100L reactor as an example, prepare raw materials according to the following quality: polyethersulfone resin (8Kg), chloroform (32Kg), precipitation solution (40Kg, of which chloroform accounts for 10Kg, and deionized water accounts for 30Kg).

[0053] Accurately weigh the above formula components respectively, add polyethersulfone resin (8Kg) and chloroform (32Kg) into a 100L reactor equipped with a water separator, agitator and heating device, start stirring, and heat the reactor to 50°C , a polyethersulfone suspension was obtained after stirring for 5 hours.

[0054] Then the temperature of the reaction kettle was lowered to normal temperature, and the polyethersulfone suspension was put into a colloid mill with a shearing and grinding function for forced dispersion. The speed of the colloid mill was 4500 rpm, and after 6 minutes of forced dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com