High-energy mixed explosive containing titanium powder and preparation method of high-energy mixed explosive

A technology of mixing explosives and titanium powder, which is applied in the field of high-energy explosives and explosives. It can solve the problems of large particle size, low reactivity and poor uniformity of titanium sponge powder, and achieve good thermal stability, mature production technology and improved explosive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

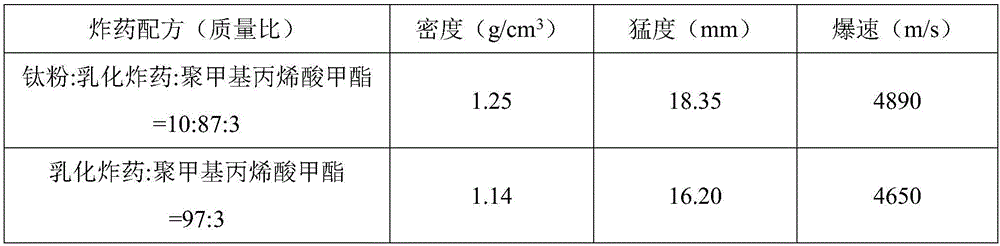

[0027] Emulsion explosive containing titanium powder: in the mixed explosive, the mass ratio of titanium powder is 10%, the mass ratio of polymethyl methacrylate is 3%, and the mass ratio of emulsion explosive is 87%. The formulation of the emulsion explosive is shown in Table 1. Add the coated titanium powder into the emulsified matrix, heat to 60°C, and then stir and mix evenly.

[0028] Using the detonation velocity and jerk test, the detonation performance of emulsion explosives containing titanium powder and no titanium powder was tested. In the jerk test, the mass of the two emulsion explosive samples was 50g; A sample of the emulsion explosive is packed into a PVC pipe with a diameter of 40 mm and a length of 300 mm. Several probes are buried on the PVC pipe, and the detonation velocity of the explosive is measured by a detonation velocity meter (on-off method). The experimental results are shown in Table 2. It can be seen from Table 2 that titanium powder can signific...

Embodiment 2

[0037] TNT explosive containing titanium powder: the mass ratio of titanium powder is 15%, the mass ratio of paraffin wax is 8%, and the mass ratio of TNT is 77%. The coated titanium powder is added to the TNT explosive, heated to 80°C, stirred and mixed evenly, and then the explosive sample is pressed into a columnar charge using a grinding tool and a hydraulic press.

[0038] In the air explosion experiment, the detonation performance of TNT explosives containing titanium powder and titanium powder-free was tested. In the experiment, the mass of the two explosive samples was 10g, and the distance between the explosive sample and the pressure sensor was 70cm. The signal was recorded by a digital oscilloscope . The experimental results are shown in Table 3. It can be seen from Table 3 that after adding titanium powder, the air explosion shock wave specific impulse of TNT explosive increased by 22.9%, and the energy density increased by 16.3%.

[0039] The preparation method o...

Embodiment 3

[0045]RDX explosive containing titanium powder: in the mixed explosive, the mass ratio of titanium powder is 20%, the mass ratio of stearic acid is 5%, and the mass ratio of RDX is 75%. The coated titanium powder is added to the RDX explosive, heated to 65°C, stirred and mixed evenly, and then the explosive sample is pressed into a column charge by using a grinding tool and a hydraulic press.

[0046] Using underwater explosion experiments, the detonation performance of RDX explosives containing titanium powder and titanium powder-free was tested. In the experiment, the mass of the two explosive samples was 10g, and the distance between the explosive sample and the pressure sensor was 120cm , using a digital oscilloscope to record the signal. The experimental results are shown in Table 4. It can be seen from Table 4 that after adding titanium powder, the underwater explosion bubble energy of the RDX explosive increased by 21.2%, and the total energy was 16.8%.

[0047] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com