Mesoporous cerium dioxide hollow spheres or mesoporous cerium dioxide/carbon composite material hollow spheres and preparation method thereof

A technology of carbon composite material and cerium oxide, which is applied in the direction of rare earth metal oxide/hydroxide, metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, etc., can solve complex operation, polluted environment, Long reaction time and other problems, to solve the effect of complex raw materials, large specific surface area and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Using cerium nitrate hexahydrate and citric acid monohydrate as raw materials, according to the ratio of the amount of substances of 1:0.1, make an aqueous solution with a concentration of 0.5mol / L, and stir magnetically for 3 hours at room temperature, and fully mix;

[0038] 2) Put the mixed solution into a microwave reaction bottle, react at 200°C for 2 minutes, after the reaction is completed, cool down to room temperature, perform suction filtration, wash with distilled water for 3 times, and then put the washed sample in a drying oven at 80°C for 8 hours , to obtain a hollow spherical ceria precursor;

[0039] 3) Place the dried hollow spherical ceria precursor in a tube furnace. Under an air atmosphere, start from room temperature and raise the temperature to 280°C at a rate of 2°C / min. The furnace was cooled to room temperature to obtain mesoporous ceria hollow sphere powder.

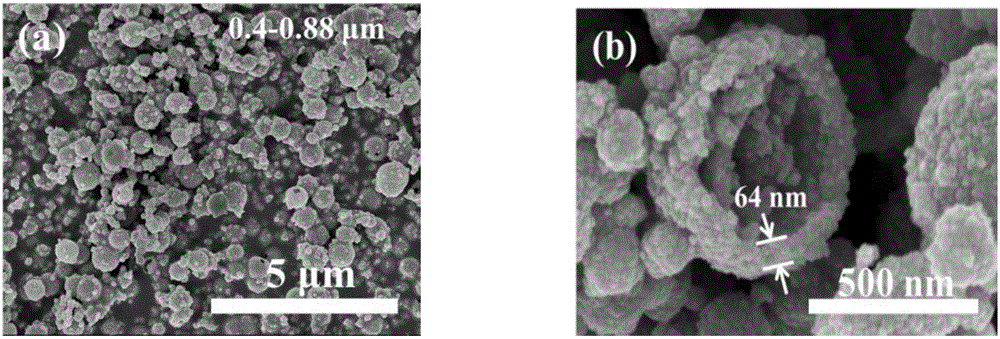

[0040] The CeO prepared by microwave hydrothermal in this example 2 The appearan...

Embodiment 2

[0042] 1) Using cerium nitrate hexahydrate and citric acid monohydrate as raw materials, according to the ratio of the amount of substances of 1:0.5, make an aqueous solution with a concentration of 0.1mol / L, stir magnetically for 4 hours at room temperature, and fully mix;

[0043] 2) Put the mixed solution into a microwave reaction bottle, react at 170°C for 2min, after the reaction is completed, cool down to room temperature, perform suction filtration, wash with distilled water for 3 times, and then put the washed sample in a drying oven at 80°C for 20h , to obtain a hollow spherical ceria precursor;

[0044] 3) Place the dried hollow spherical ceria precursor in a tube furnace, raise the temperature up to 300°C at a rate of 0.5°C / min in an air atmosphere, keep it warm for 1 hour, and cool it down to room temperature with the furnace after the heat preservation is over. The mesoporous ceria hollow sphere powder is obtained.

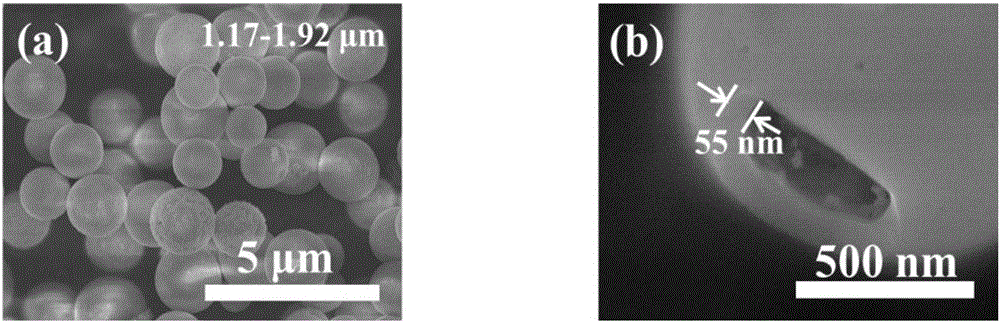

[0045] The CeO prepared by microwave hydrother...

Embodiment 3

[0047] 1) Using cerium nitrate hexahydrate and citric acid monohydrate as raw materials, according to the ratio of the amount of substances of 1:0.7, make an aqueous solution with a concentration of 0.1mol / L, and stir magnetically for 2 hours at room temperature, and fully mix;

[0048] 2) Put the mixed solution into a microwave reaction bottle, react at 150°C for 2 minutes, after the reaction is completed, cool down to room temperature, perform suction filtration, wash with distilled water for 3 times, and then put the washed sample in a drying oven at 80°C for 12 hours , to obtain a hollow spherical ceria precursor;

[0049] 3) Place the dried hollow spherical ceria precursor in a tube furnace, raise the temperature up to 600°C at a rate of 2°C / min in an Ar atmosphere, keep it for 1 hour, and cool it down to room temperature with the furnace after the hold. Obtain mesoporous ceria / carbon composite hollow spheres.

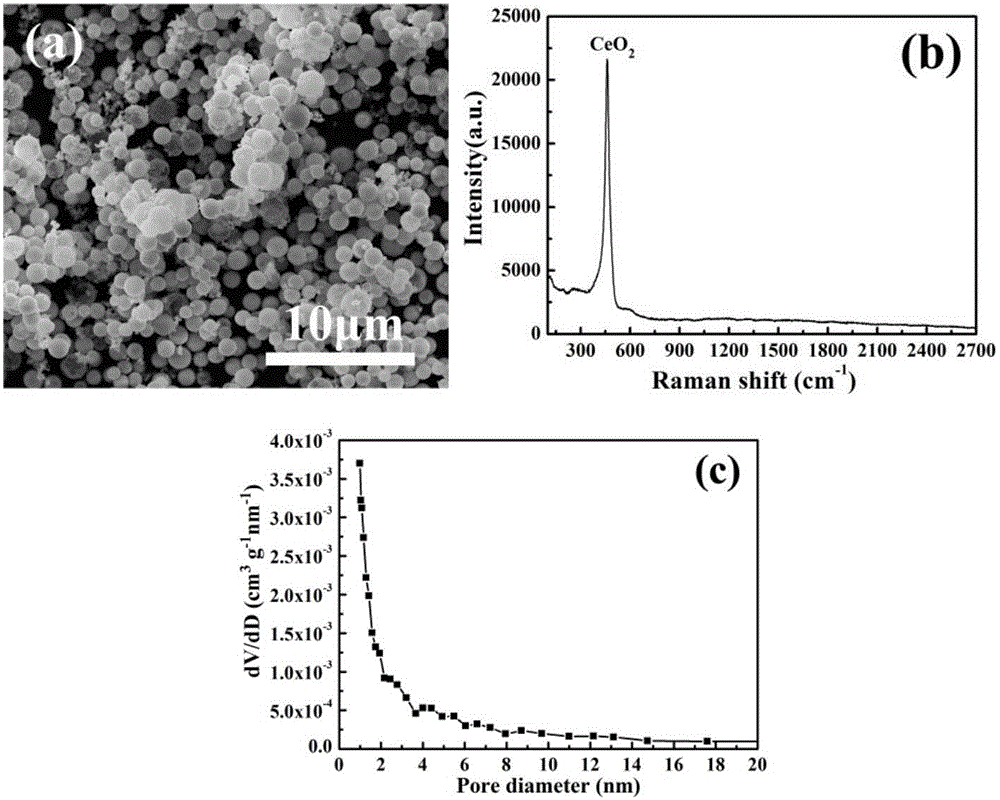

[0050] The CeO prepared by microwave hydrothermal in this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com