Two-way spray heat-removing vacuum tower inner part provided with dual-flow tray for despumating

A technology of decompression tower and flow tray, which is used in distillation separation, vacuum distillation, fractionation and other directions, can solve the problems of enlarged tower diameter, increased reflux flow, and reduced reflux temperature and thermal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

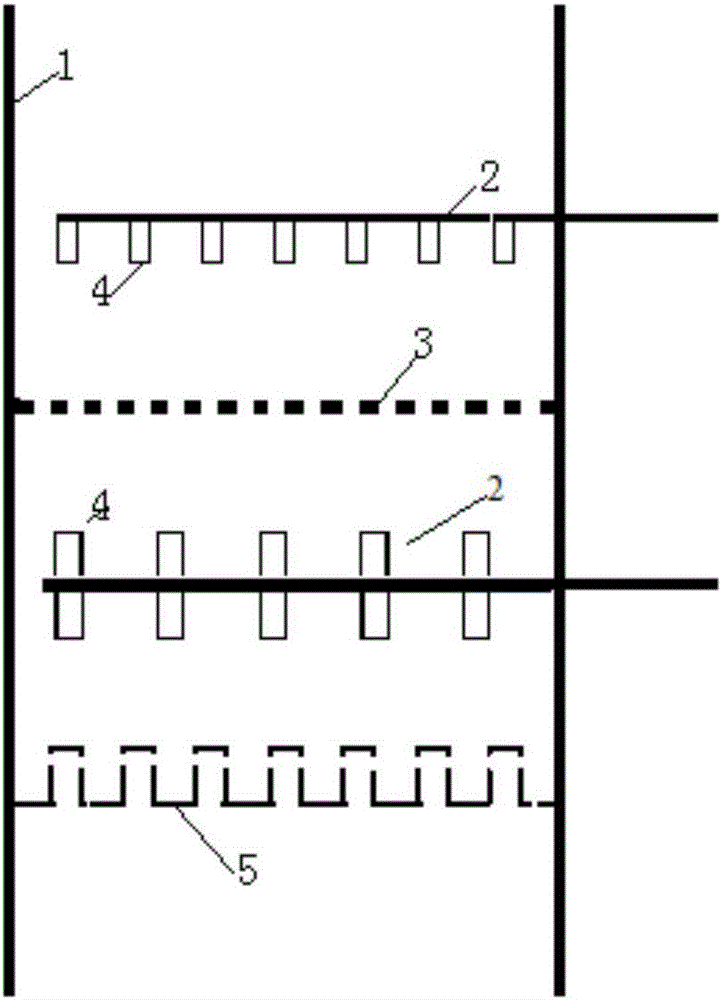

[0023] A decompression tower internal part with two-way spray heat extraction with cross-flow tray defoaming is integrated through the following structure: each heat extraction section is provided with two layers of dendritic jet liquid distributors (2), and the upper layer The atomizing nozzle (4) of the liquid distributor (2) sprays downward, and the lower liquid distributor (2) is provided with two groups of atomizing nozzles (4) upward and downward; the atomizing liquid of the upper liquid distributor (2) The droplets are relatively large, and the mist entrainment rate of the airflow is less than 10%; the atomized droplets of the lower liquid distributor (2) are finer, which enhances heat transfer, and are sprayed to the through-flow sieve tray (3) for coalescence and recovery; two layers of tree branches A layer of through-flow sieve trays (3) are installed between the jet-shaped liquid distributors (2), the plate surface opening ratio is 30-60%, and the hole diameter is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com