Polytetrafluoroethylene composite microwave dielectric material and preparation method thereof

A technology of microwave dielectric materials and polytetrafluoroethylene, applied in the direction of dielectric materials, circuit substrate materials, chemical instruments and methods, etc., to achieve the effect of improving thermal expansion coefficient, ensuring isotropy, and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]

[0045]

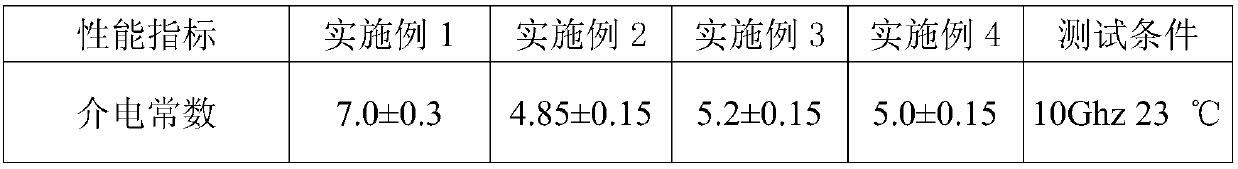

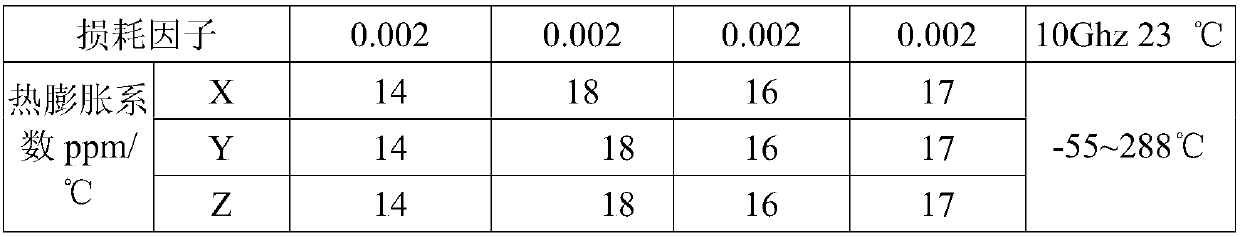

[0046] Table 1

[0047] Such as figure 1 As shown, in this embodiment, the printed circuit board substrate includes a composite microwave dielectric material plate 200 and metal foils 100 laminated on both sides of the composite microwave dielectric material plate 200 respectively. The metal foil layer 100 is a low-profile electrolytic copper foil, and the thickness of the metal foil layer 100 is 35 um. The thickness of the composite microwave dielectric material sheet 200 is 0.25 mm. Its electrical performance parameters are shown in Table 1.

[0048] The manufacturing method of the printed circuit board substrate of this embodiment includes the following steps:

[0049] Weigh 5 kg of PTFE emulsion (Daikin D210, PTFE solid content 60%), and 6 kg of microwave dielectric ceramic powder filler (BaO-Sm 2 O 3 -TiO 2 System, D50 particle size 2um, dielectric constant 90), glass fiber powder 1 kg (Jushi EMG13-250, diameter 13um, length 50um) is mixed with a mixer for 1 ...

Embodiment 2

[0057] Such as figure 1 As shown, in this embodiment, the printed circuit board substrate includes a composite microwave dielectric material plate 200 and metal foils 100 laminated on both sides of the composite microwave dielectric material plate 200 respectively. The metal foil layer 100 is a low-profile electrolytic copper foil, and the thickness of the metal foil layer 100 is 18 um. The thickness of the composite microwave dielectric material sheet 200 is 0.25 mm. Its electrical performance parameters are shown in Table 1.

[0058] The manufacturing method of the printed circuit board substrate of this embodiment includes the following steps:

[0059] Weigh 10 kilograms of PTFE emulsion (Dajin D210, PTFE solid content 60%), 3.5 kilograms of microwave dielectric ceramic powder filler (BaO-ZnO-TiO 2 System, D50 particle size 5um, dielectric constant 36), 1.5 kg of glass fiber powder (Jushi EMG13-250, diameter 13um, length 50um) is mixed with a mixer for 1 hour at 1500 revolution...

Embodiment 3

[0067] Such as figure 1 As shown, in this embodiment, the printed circuit board substrate includes a composite microwave dielectric material plate 200 and metal foils 100 laminated on both sides of the composite microwave dielectric material plate 200 respectively. The metal foil layer 100 is a low-profile electrolytic copper foil, and the thickness of the metal foil layer 100 is 18 um. The thickness of the composite microwave dielectric material sheet 200 is 0.25 mm. Its electrical performance parameters are shown in Table 1.

[0068] The manufacturing method of the printed circuit board substrate of this embodiment includes the following steps:

[0069] Weigh 10 kg of PTFE emulsion (Dajin D210, PTFE solid content 50%) microwave dielectric ceramic powder filler 4 kg (BaO-ZnO-TiO 2 System, D50 particle size 5um, dielectric constant 36), 1 kilogram of microwave fiber powder (Jushi EMG13-250, diameter 13um, length 50um) is mixed with a mixer for 1 hour at 1500 revolutions to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com