Palladium oxide catalyst used for direct formic acid fuel cell and preparation method thereof

A formic acid fuel cell and palladium oxide technology, which is applied in catalyst activation/preparation, fuel cells, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of small electrocatalyst particle size, non-recyclability, and high cost , to achieve the effect of short reaction time, energy saving and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

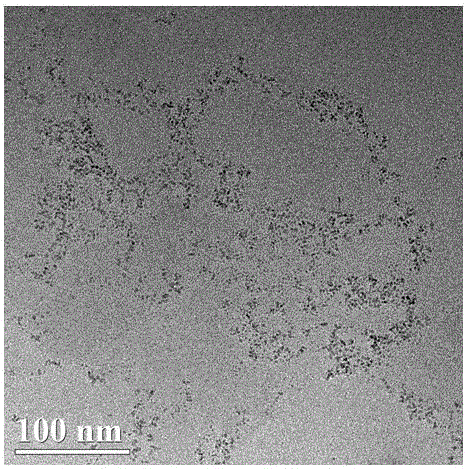

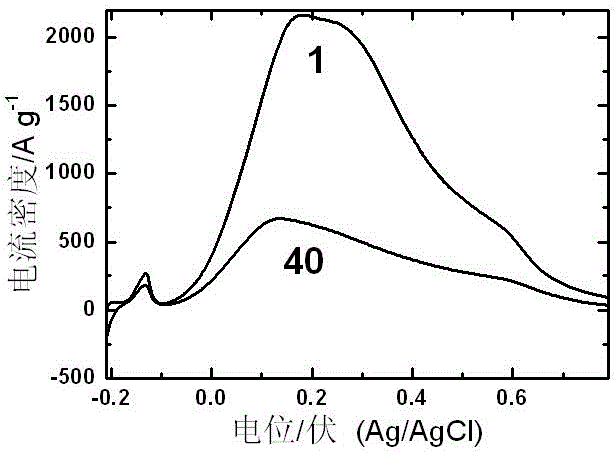

[0033] 2.5 ml prepared 0.12 mol L -1 Palladium chloride solution was added to 100 ml of water, and then 1.5 × 10 -3 mol of sodium citrate, the mol ratio of sodium citrate to palladium chloride is 5:1. Adjust the pH to 9; place the solution in a microwave reactor with a power of 1200W, microwave reflux for 17 minutes and keep magnetic stirring to obtain a palladium oxide colloidal solution; after the palladium oxide colloidal solution is cooled, add 120 mg of carbon powder to collect the palladium oxide; Finally, suction filtration, the filter cake was washed, dried in vacuum, and ground to obtain a carbon-supported palladium oxide catalyst, and the mass ratio of palladium oxide in the palladium oxide catalyst was 20%. figure 1 The transmission electron micrograph of the palladium oxide colloid prepared for the present embodiment, from figure 1 It can be seen that the average particle size of palladium oxide is 2.5 nm, and the distribution is uniform. figure 2 For the X-ray...

Embodiment 2

[0035] 2.5 ml prepared 0.12 mol L -1 Palladium chloride solution was added to 100 ml of water, and then 1.5 × 10 -4 mol sodium citrate, the molar ratio of sodium citrate to palladium chloride is 0.5:1. Adjust the pH to 13; place the solution in a microwave reactor with a power of 600W, microwave reflux for 30 minutes and keep magnetic stirring to obtain a palladium oxide colloidal solution; after the palladium oxide colloidal solution is cooled, add 47 mg of carbon nanotubes to collect palladium oxide Finally, suction filtration, the filter cake is washed, vacuum-dried, and ground to obtain a carbon-supported palladium oxide catalyst, and the mass ratio of palladium oxide in the palladium oxide catalyst is 40%. The average particle size of the palladium oxide prepared in this example is 2.2 nm, and it can be seen from the X-ray diffraction pattern that the catalyst prepared in this example is palladium oxide. The palladium oxide catalyst prepared in this embodiment is 0.5 mo...

Embodiment 3

[0037] 4 ml prepared 0.12 mol L -1 Palladium chloride solution was added to 100 ml of water, and then 1.32 × 10 -3 mol sodium citrate, the mol ratio of sodium citrate to palladium chloride is 2.75:1. Adjust the pH to 11; place the solution in a microwave reactor with a power of 1500W, microwave reflux for 3 minutes and keep magnetic stirring to obtain a palladium oxide colloidal solution; after the palladium oxide colloidal solution is cooled, add 400 mg of carbon powder to collect the palladium oxide; Finally, suction filtration, the filter cake was washed, vacuum-dried, and ground to obtain a carbon-supported palladium oxide catalyst, and the mass ratio of palladium oxide in the palladium oxide catalyst was 10%. The average particle size of the palladium oxide catalyst prepared in this example is 2.3 nm. 0.5 mol L at room temperature -1HCOOH+0.5 mol L -1 h 2 SO 4 In solution, the scanning speed is 20mV s -1 , the peak current density of the palladium oxide catalyst p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com