Methyl methacrylate modified silicon resin coating and preparation method thereof

A technology of methyl methacrylate and modified resin, applied in coatings and other directions, can solve the problems of general silicone resin adhesion performance, poor mechanical properties and anti-corrosion requirements, affecting thermal protection performance, etc., to speed up the coating process. Curing speed, stable product performance, anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

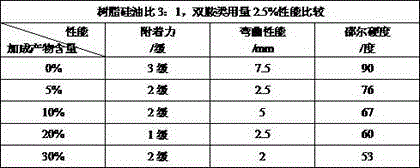

Embodiment 1

[0039] Synthesis of addition products: Add 67.43g of trimethoxysilane, 101.354g of toluene and 0.926g of platinum catalyst solution into a 500ml three-necked flask equipped with a reflux condenser, a thermometer and a magnet, and raise the temperature to 60°C. Add 50.06 g of methyl methacrylate dropwise into the liquid funnel, react for 1 hour, then raise the temperature to 85°C, react for 2 hours and then lower the temperature to below 40°C and carry out vacuum distillation to 120°C to obtain the addition product.

[0040] The molar ratio of trimethoxysilane to toluene is 1:2, and the molar ratio of methyl methacrylate is 1.1:1; the amount of chloroplatinic acid is the sum of the mass of trimethoxysilane and methyl methacrylate (50-100)* 10 -6 ;

[0041] Synthesis of modified resin (5% addition product, mole fraction): put 11.12g of addition product, 61.30g of methyltrimethoxysilane, and 99.15g of phenyltrimethoxysilane into a three-necked bottle, drop 8.74g Water and an ap...

Embodiment 2

[0047] Synthesis of addition products: Add 153.25g of trimethoxysilane, 92.14g of toluene and 1.996g of platinum catalyst solution into a 500ml three-necked flask equipped with a reflux condenser, a thermometer and a magnet, and raise the temperature to 60°C. Add 100.12 g of methyl methacrylate dropwise into the liquid funnel, react for 1 hour, then raise the temperature to 85°C, react for 2 hours and then lower the temperature to below 40°C and carry out vacuum distillation to 120°C to obtain the addition product. The molar ratio of trimethoxysilane to toluene is 1:1, and the molar ratio of methyl methacrylate is 1.25:1; the amount of chloroplatinic acid is the sum of the mass of trimethoxysilane and methyl methacrylate (50-100)* 10 -6 ;

[0048] Synthesis of modified resin (10% addition product, mole fraction): put 9g of addition product, 22.08g of methyltrimethoxysilane, and 40.125g of phenyltrimethoxysilane into a three-necked bottle, drop 8.735g of water , and add an ap...

Embodiment 3

[0055] Addition product synthesis and equipment are as above;

[0056] Synthesis of modified resin (20% addition product, mole fraction): put 22.24g of addition product, 20.433g of methyltrimethoxysilane, and 49.57g of phenyltrimethoxysilane into a three-necked bottle, drop 9g of water , and add an appropriate amount of hydrochloric acid as a catalyst (keep the drop rate of 1-2 seconds per drop); hydrolyze at room temperature (30°C) for one hour; raise the temperature to 60°C, and react for 2 hours; after the condensation is completed, change the distillation device and heat up to 85°C. The product methanol is distilled out (about three hours), and a certain amount of petroleum ether is added after the reaction is complete, so that the mass fraction of the resin is 90%.

[0057] Synthetic silicone oil: put 91.15g of methylphenyldimethoxysilane into a three-necked bottle, drop in 9g of water, and add an appropriate amount of hydrochloric acid as a catalyst (keep the water drop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com