Temperature measurement system based on ysz:re fluorescence lifetime measurement and its test method and application

A technology of temperature measurement and fluorescence lifetime, applied in the direction of measuring heat, thermometers and thermometers with physical/chemical changes, etc., can solve the problem of low measurement temperature, and achieve high temperature accuracy, wide measurement temperature range, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

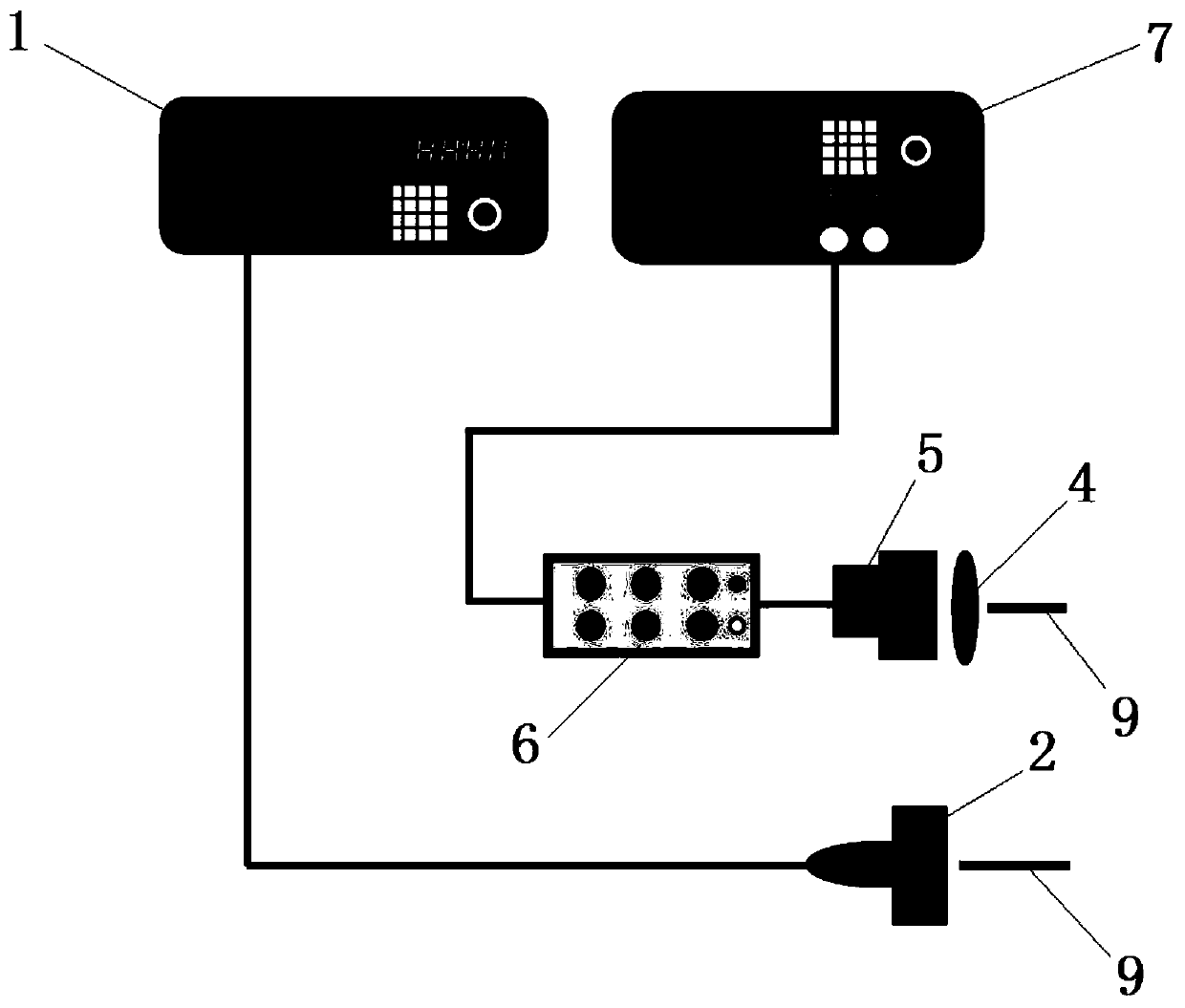

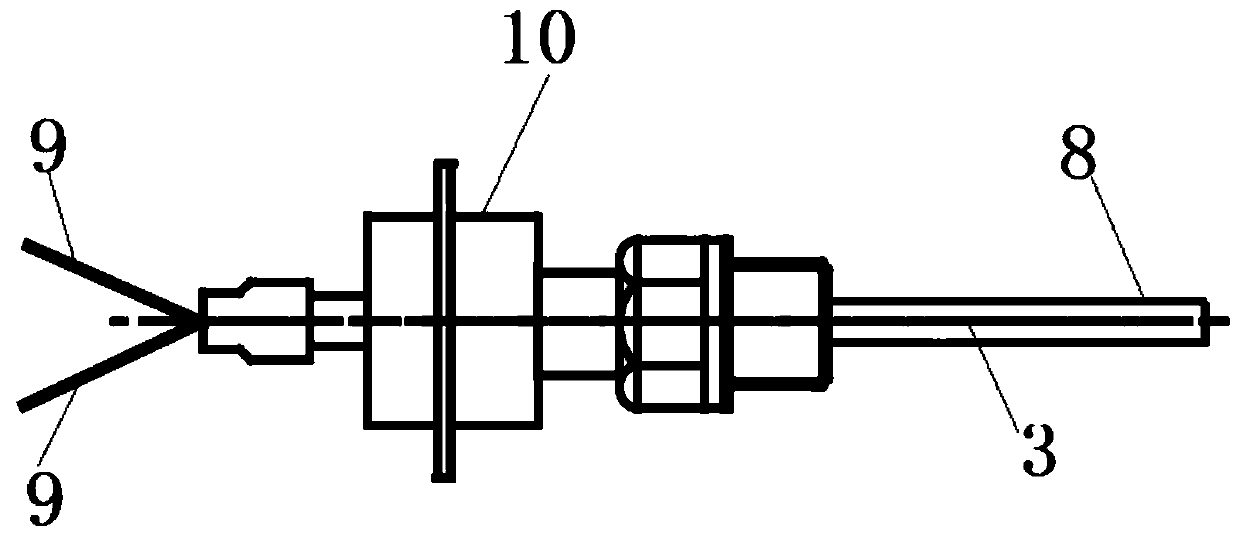

[0052] Such as Figure 1-2 As shown, the temperature measurement system based on YSZ: Re fluorescence lifetime measurement includes a signal transmitter 1, a UV-LED ultraviolet light source electrically connected to the signal transmitter 1, a temperature measurement probe 3, and a temperature measurement probe The temperature signal processing unit used in conjunction with the needle 3. The temperature signal processing unit includes a filter 4, a photomultiplier tube detector 5, a resistance box 6 and an oscilloscope 7 electrically connected to the photomultiplier tube detector 5 in turn, and a temperature measurement probe The surface of 3 is sprayed with YSZ:Re fluorescent layer 8, and is connected to UV-LED ultraviolet light source 2 and filter 4 through optical fiber 9;

[0053] Among them, the temperature measuring probe 3 is a single crystal alumina temperature measuring probe coated with a YSZ:Re phosphor layer 8 by plasma spraying. The chemical formula of YSZ:Re in YSZ...

Embodiment 2

[0073] Firstly, the YSZ:Dy powder (with a particle size of 60μm) was prepared by the reverse co-precipitation method, and then the single crystal alumina was cleaned and sandblasted. The 10 μm YSZ:Dy phosphor layer 8 is prepared by plasma spraying technology. Spraying parameters: spraying current is 400A, voltage is 150V, Ar flow is 45L / min, H 2 The flow rate is 45L / min, the distance between the spray gun and the substrate is 150mm, and the powder delivery rate is 5g / min. The single crystal alumina sprayed on the YSZ:Dy phosphor layer 8 is connected to the optical fiber 9 and divided into two outputs. One is connected to a UV-LED ultraviolet light source 2 with a wavelength of 355nm and a signal transmitter 1. The signal transmitter 1 turns a continuous light source into a pulsed light source with a pulse width of 1 ms and a pulse period of 100 ms. A channel that connects a 550nm high-pass filter, a 600nm low-pass filter, a resistance box 6, an oscilloscope 7, and connects the...

Embodiment 3

[0077] Firstly, YSZ:Eu powder (with a particle size of 80μm) was prepared by the sol-gel liquid phase method, and then the single crystal alumina was cleaned and sandblasted. The 10 μm YSZ:Eu phosphor layer 8 is prepared by plasma spraying technology. Spraying parameters: spraying current is 400A, voltage is 150V, Ar flow is 60L / min, H 2 The flow rate is 20L / min, the distance between the spray gun and the substrate is 150mm, and the powder delivery rate is 5g / min. The single crystal alumina sprayed on the YSZ:Eu phosphor layer 8 is connected to the optical fiber 9 and divided into two outputs. One is connected to a UV-LED ultraviolet light source 2 with a wavelength of 385nm and a signal transmitter 1. The signal transmitter 1 turns a continuous light source into a pulsed light source with a pulse width of 1 ms and a pulse period of 100 ms. A channel that connects a 570nm high-pass filter, a 625nm low-pass filter, a resistance box 6, an oscilloscope 7, and connects the signal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com