Mean flow rate measuring instrument of gas-solid two-phase flow pipeline

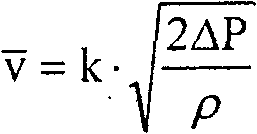

A technology of fluid pipeline and average flow velocity, which is applied in fluid velocity measurement, fluid velocity measurement by pressure difference, velocity/acceleration/impact measurement, etc. It can solve problems such as uneven flow field distribution, wear, and easy blockage of pressure-sensing holes. Achieve the effects of avoiding dust accumulation and clogging, long service life and stable flow coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

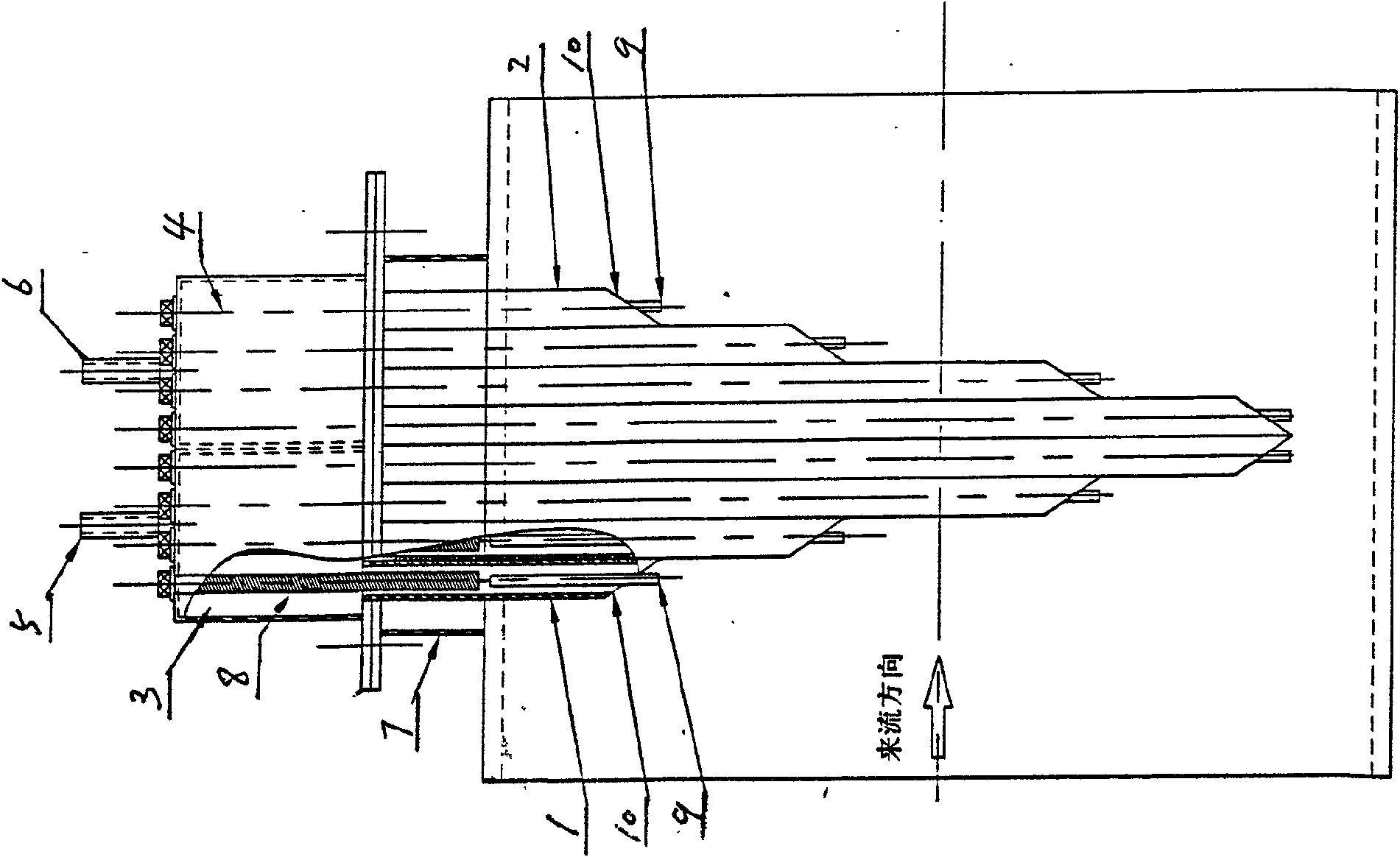

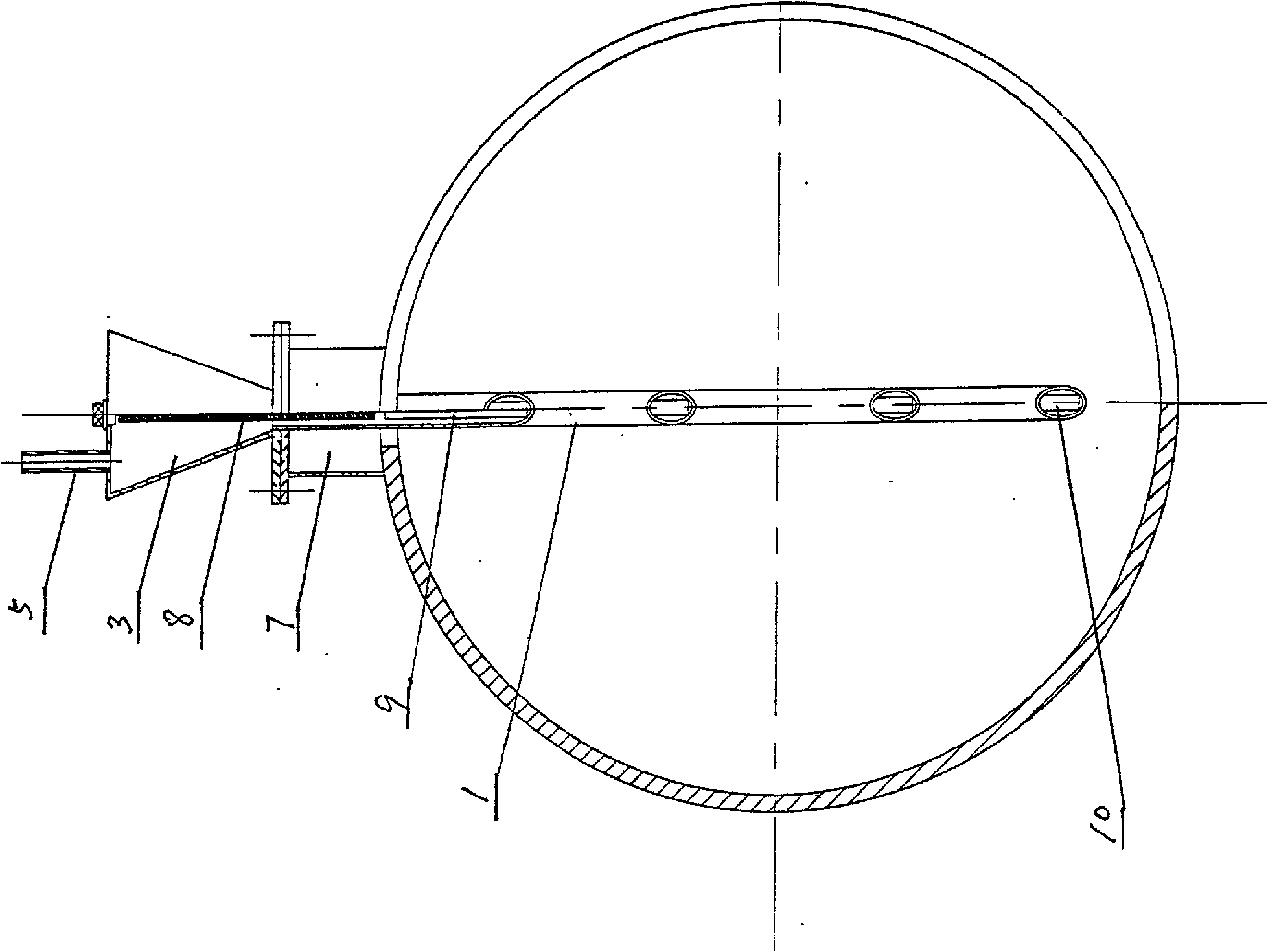

[0028] Describe an embodiment in detail below in conjunction with accompanying drawing: as figure 1 , figure 2 As shown, the gas-solid two-phase fluid pipeline average flow rate measuring instrument is a typical circular section arrangement, which is inserted into the fluid pipeline from above the fluid pipeline to directly measure the pressure difference. The pressure-sensing tubes inserted into the fluid pipeline and fixed in a row are composed of four full-pressure pressure-sensing tubes 1 and four negative-pressure pressure-sensing tubes 2 connected side by side. The two adjacent ones in the middle of the full-pressure pressure-sensing tube 1 and the negative-pressure pressure-sensing tube 2 are the longest, and the ones on both sides are successively shorter.

[0029] The upper ends of the full-pressure pressure-sensing tube 1 and the negative-pressure-sensing tube 2 protrude from the fluid pipeline and lead into the full-pressure signal equalizing chamber 3 and the neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com