Optical microscopic imaging method and device for online monitoring in high temperature state

A high-temperature state, optical microscopy technology, applied in measurement devices, optics, microscopes, etc., can solve problems such as the close distance between the microscope and the heat source, and the system is complex, achieving adjustable test environment, large imaging working distance, and wide temperature measurement range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

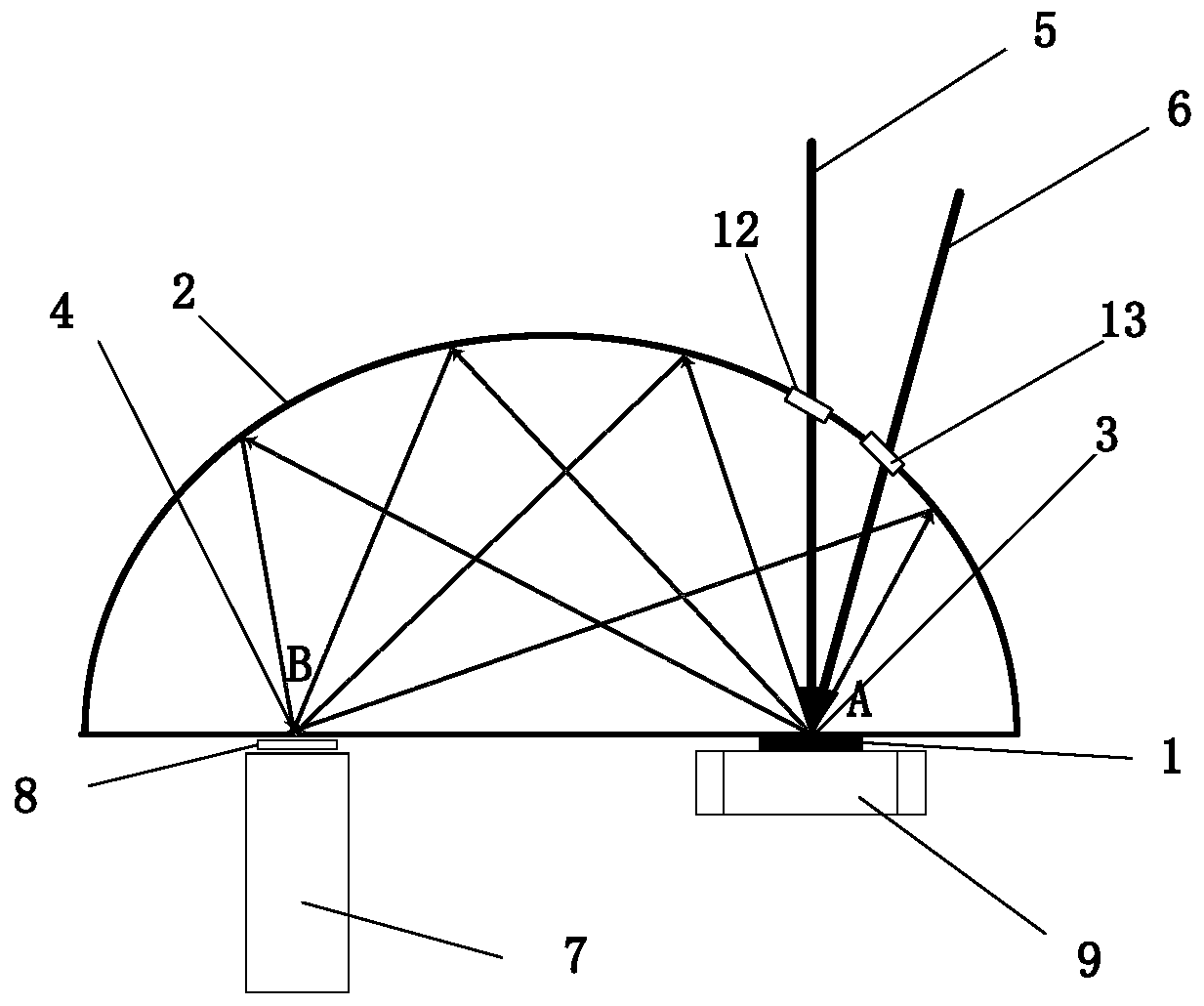

[0031] see figure 1 , the sample 1 is placed at the focal point A of the conjugate imaging surface 2, and the optical microscope 7 is placed at the focal point B; the sample is installed on the position adjustment mechanism 9, which can realize the adjustment of the position of the sample in the three-dimensional direction, ensuring that the measured The center of the area is always on focus A. The sample 1 is heated by the laser 6 to achieve a high temperature state; the laser light source is located outside the conjugate imaging plane, and the heating laser 6 enters through the light window 13 to heat the sample 1 . The illumination light 5 irradiates the surface of the sample 1 through the light window 12 and forms an image at the focal point B. A filter 8 is installed in front of the optical microscope to filter out laser signals to eliminate interference to imaging. Use an optical microscope to magnify the conjugate image to obtain a microscopic image.

Embodiment 2

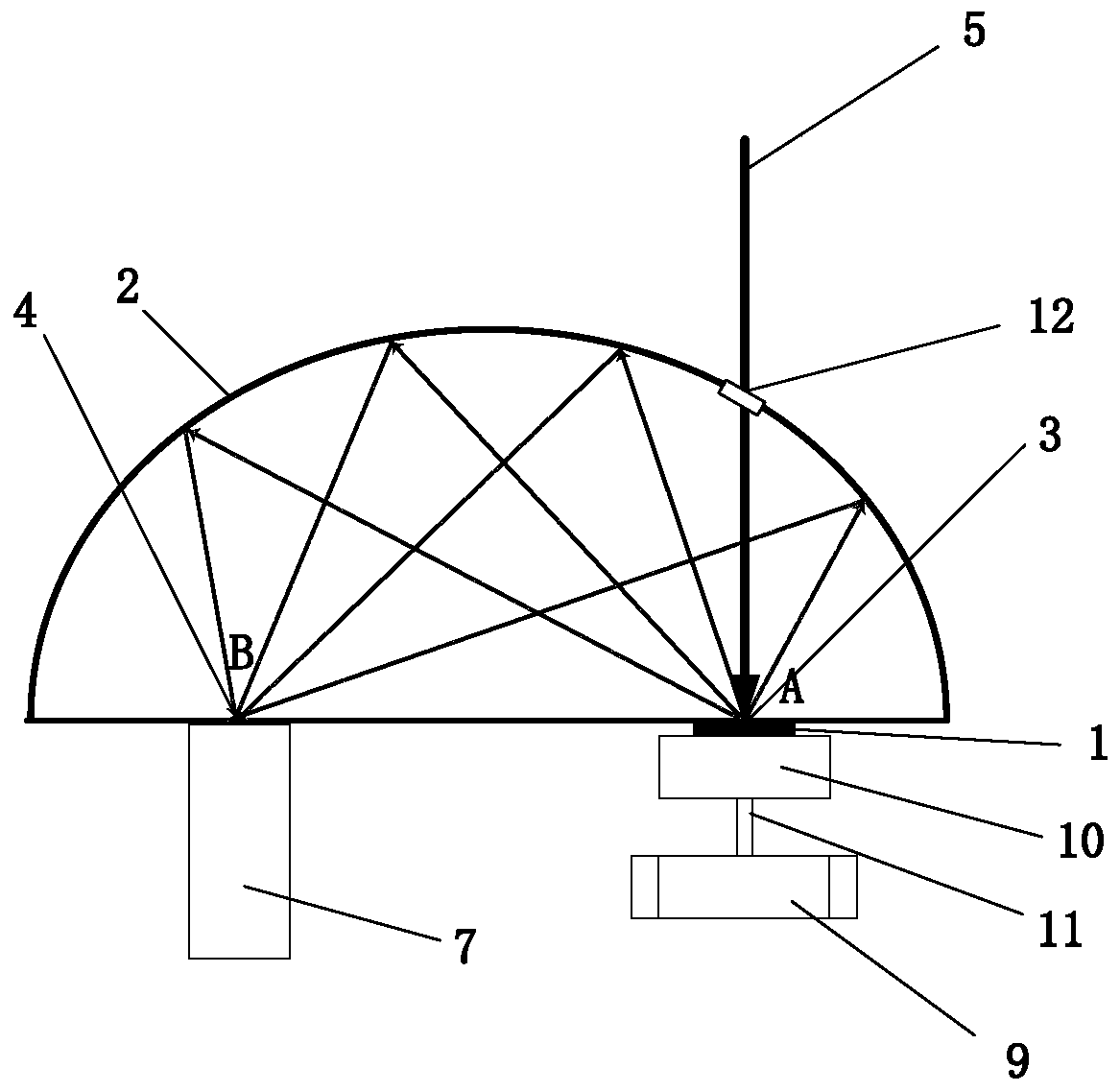

[0033] see figure 1 , the sample 1 is placed at the focal point A of the conjugate imaging surface 2, and the optical microscope 7 is placed at the focal point B; the sample is installed on the position adjustment mechanism 9, which can realize the adjustment of the position of the sample in the three-dimensional direction, ensuring that the measured The center of the area is always on focus A. A heater 10 is arranged on the back of the sample to realize a high temperature state; a heat insulation assembly 11 is arranged between the heater 10 and the position adjustment mechanism 9 . The illumination light 5 irradiates the surface of the sample 1 through the light window 12 and forms an image at the focal point B. Use an optical microscope to magnify the conjugate image to obtain a microscopic image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com