Connector of self-sealing flat plate type solid oxygenated fuel cell and preparation method

A fuel cell and self-sealing technology, which is applied to fuel cell parts, fuel cells, sealing/supporting devices, etc., can solve the problems of high temperature sealing difficulty and large sealing area, simplifying the manufacturing process and overcoming the sealing problem. , reduce the effect of commercial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

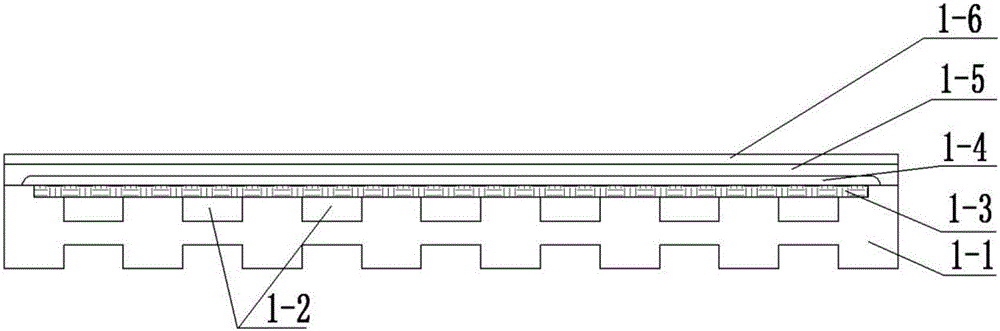

[0032] in a 10×10cm 2 Process a gas channel 1-2 and a 9×9×1cm on the metal connecting body 1-1 3 First use strontium oxide to fill the gas channel 1-2, then inject the mixture of stainless steel powder and brazing filler metal into the groove, fill it up and compact it, and braze it at a temperature higher than the battery’s working temperature, and obtain porous after brazing The metal layer 1-3; the surface of the porous metal layer 1-3 is machined into a plane. Immersing the integrated metal connection in water dissolves the strontium oxide in the gas path. Finally, the Ni / YSZ anode, YSZ electrolyte layer, and LSM cathode were sequentially prepared by atmospheric plasma spraying, and the test cells exhibited good voltage and power output.

Embodiment 2

[0034] in a 19×19cm 2 Process a gas passage 1-2 and a 18×18×0.8cm on the metal connecting body 1-1 3 Firstly, strontium oxide is used to fill the gas channel, and then the mixture of stainless steel powder and pore-forming agent is injected into the groove, filled and compacted, and sintered at a temperature higher than the working temperature of the battery. After sintering, a porous metal layer is obtained 1-3 ; The surface of the porous metal layer 1-3 is machined into a plane. Immerse the integral terminal in water to dissolve the strontium oxide in the gas path. Finally, the Ni / YSZ anode, YSZ electrolyte layer, and LSCF cathode were sequentially prepared by atmospheric plasma spraying, and the test cell exhibited good voltage and power output.

Embodiment 3

[0036] in a 21×21cm 2 A gas passage and a 20×20×1cm 3 The grooves are filled with strontium oxide first, and then the mixture of stainless steel powder and pore-forming agent is melted by selective laser melting technology to form a porous metal layer 1-3 in the groove; the surface of the porous metal layer 1-3 is machined into a flat. Immerse the integral terminal in water to dissolve the strontium oxide in the gas path. Finally, the Ni / ScSZ anode, ScSZ electrolyte layer, and LSCF cathode were sequentially prepared by atmospheric plasma spraying, and the test cell exhibited good voltage and power output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com