Thermoplastic high voltage cable insulating material and preparation method thereof

A technology for high-voltage cables and insulating materials, applied in the direction of plastic/resin/wax insulators, insulators, organic insulators, etc., can solve the problems of breakdown strength drop, space charge accumulation, cable degassing, etc., to suppress space charge injection and improve Volume resistivity, effect of improving breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

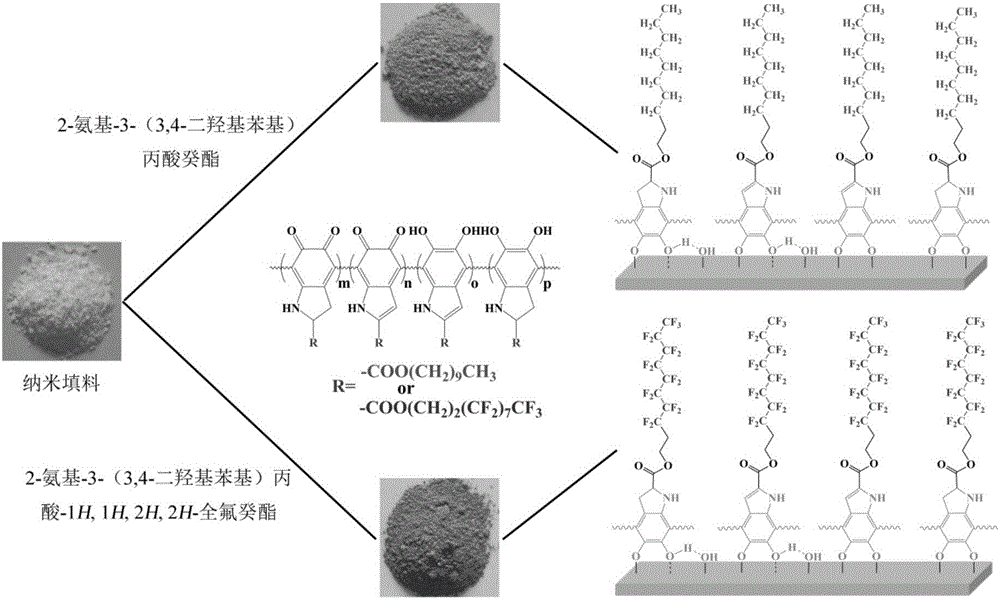

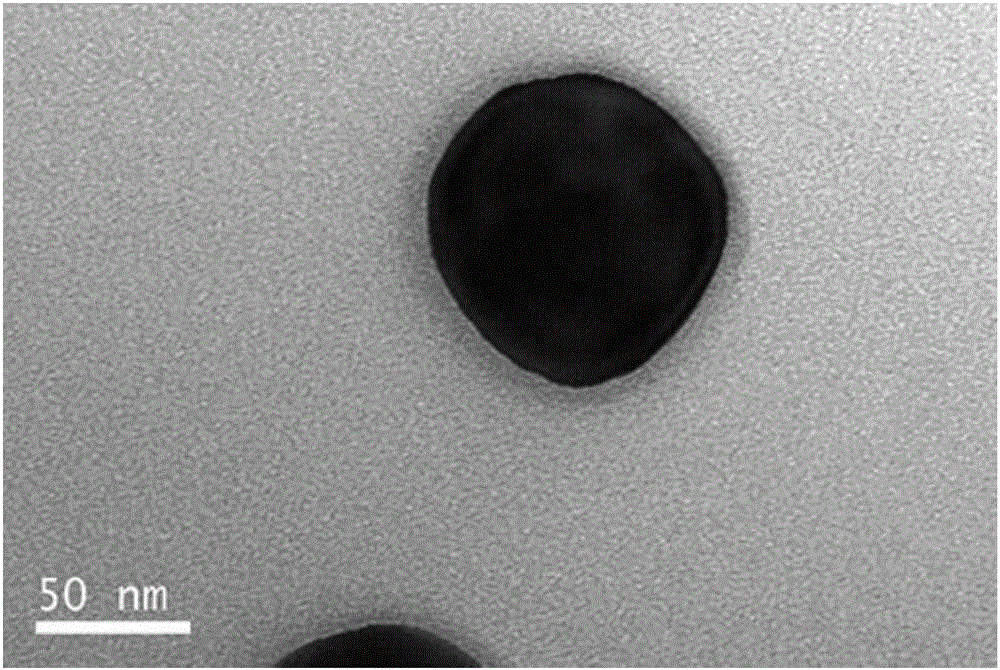

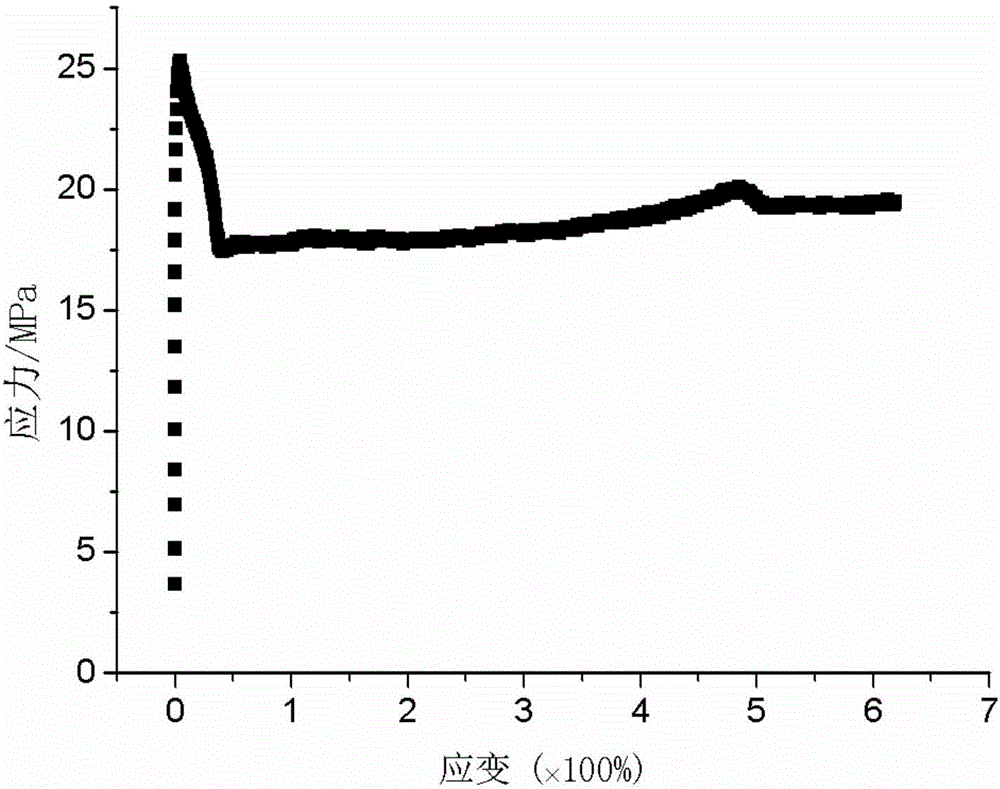

[0045] This embodiment relates to a thermoplastic high-voltage cable insulation material, which is composed of 90 parts of isotactic polypropylene and 10 parts of ethylene-octene copolymer as the matrix, and 6 parts of 2-amino-3-(3,4 -Dihydroxyphenyl)propionic acid-1H,1H,2H,2H-perfluorodecyl modified barium titanate nanoparticles as filler composition. Wherein 2-amino-3-(3,4-dihydroxyphenyl)propionic acid-1H,1H,2H,2H-perfluorodecyl modified barium titanate nanoparticles were prepared by the following steps:

[0046] A. Dopamine with long-chain structure: 1H,1H,2H,2H-perfluorodecyl alcohol reacts with L-3,4-dihydroxyphenylalanine to obtain 2-amino-3-(3,4-dihydroxy phenyl)propionic acid-1H,1H,2H,2H-perfluorodecyl ester. The synthesis of this long-chain dopamine adopts the method in the literature (Manolakis, I. et al., Macromol. Rapid Commun. 2014, 35, 71-76.).

[0047] B. Dopamine-modified barium titanate nanoparticles with long-chain structure: 2-amino-3-(3,4-dihydroxyphenyl...

Embodiment 2

[0050] This embodiment relates to a thermoplastic high-voltage cable insulation material. The insulation material is made of 90 parts of isotactic polypropylene and 10 parts of propylene-ethylene copolymer as a matrix, and 5 parts of 2-amino-3-(3,4- Dihydroxyphenyl)decyl propionate modified strontium titanate nanoparticles as filler composition. The strontium titanate nanoparticles modified by decyl 2-amino-3-(3,4-dihydroxyphenyl)propionate are prepared through the following steps.

[0051] A. Dopamine with long chain structure: 1-decanol reacts with L-3,4-dihydroxyphenylalanine to obtain decyl 2-amino-3-(3,4-dihydroxyphenyl)propionate. The synthesis of this long-chain dopamine adopts the method in the literature (Manolakis, I. et al., Macromol. Rapid Commun. 2014, 35, 71-76.).

[0052] C. Dopamine-modified strontium titanate nanoparticles with long-chain structure: Dissolve decyl 2-amino-3-(3,4-dihydroxyphenyl)propionate in isopropanol, and at the same time, strontium titana...

Embodiment 3

[0055] This embodiment relates to a thermoplastic high-voltage cable insulating material, which is composed of 100 parts of isotactic polypropylene as a matrix and 4 parts of 2-amino-3-(3,4-dihydroxyphenyl)propionic acid-1H , 1H, 2H, 2H-perfluorodecyl ester modified magnesium oxide nanoparticles as filler composition. The preparation steps of magnesium oxide nanoparticles modified with decyl 2-amino-3-(3,4-dihydroxyphenyl)propionate are the same as those in Example 2, except that the nanoparticles used are magnesium oxide.

[0056] This embodiment also relates to a preparation method of a thermoplastic high-voltage cable insulating material, which comprises 100 parts of isotactic polypropylene, 4 parts of dopamine-modified magnesium oxide nanoparticles, 0.1 part of antioxidant 1010 and 0.1 part The antioxidant 168 was added to the internal mixer, and kneaded at 200°C for 8 minutes to obtain a thermoplastic high-voltage cable insulation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com