Cloth-shaped nickel-based brazing material and preparation method and application thereof

A brazing material, nickel-based technology, applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of limited hardness, nickel-based brazing material is not easy to form, achieve good anti-corrosion performance, and expand the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

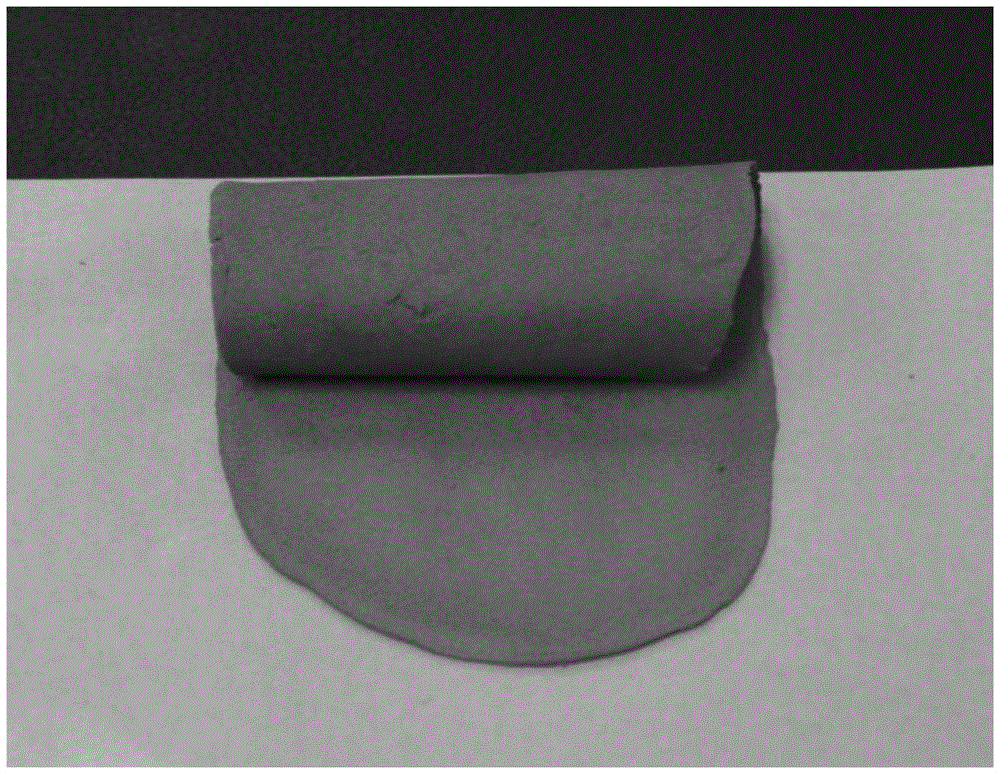

Image

Examples

Embodiment 1

[0026] Element mass percentage of nickel-based alloy powder

[0027] Carbon content: 0.2%

[0028] Silicon content: 3.5%

[0029] Boron content: 2.2%

[0030] Chromium content: 7.5%

[0031] Iron content: 3%

[0032] Nickel content: all remaining

[0033] The oxygen content of the nickel-based alloy powder is 300 ppm, the particle size is 200 mesh, and the weight is 350 g.

[0034] The cemented carbide powder is 50 g of 250 mesh WC (tungsten carbide) powder and 50 g of 200 mesh TiC (titanium carbide) powder.

[0035] Choose 50g polyethylene glycol PEG-200 as binder.

[0036] First, use a ball mill to mix the nickel-based alloy powder and the cemented carbide powder evenly, then add the evenly mixed powder into the binder and use ultrasonic dispersion to disperse evenly, and then carry out the system of uniformly dispersed powder and binder Coating and fixing between two layers of silicone oil paper, applying pressure to make the thickness 2mm, and molding and curing at ...

Embodiment 2

[0040] Element mass percentage of nickel-based alloy powder

[0041] Carbon content: 0.85%

[0042] Silicon content: 4.5%

[0043] Boron content: 3.4%

[0044] Chromium content: 16%

[0045] Iron content: 8%

[0046] Nickel content: all remaining

[0047] The oxygen content of the nickel-based alloy powder is 200 ppm, the particle size is 250 mesh, and the weight is 300 g.

[0048] The cemented carbide powder is 150 g of 250 mesh WC (tungsten carbide) powder.

[0049] Bisphenol A type epoxy resin E-44, average epoxy value 0.44, 40g; low molecular weight polyamide curing agent 651, amine value 380-420, 10g.

[0050] First, use a ball mill to mix the nickel-based alloy powder and the cemented carbide powder evenly, then add the evenly mixed powder into the binder and use ultrasonic dispersion to disperse evenly, and then carry out the system of uniformly dispersed powder and binder Coating and fixing between two layers of silicone oil paper, applying pressure to make the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com