Production method of conductive-toughening melt-blown composite nonwoven fabric

A non-woven fabric and melt-blown technology, which is applied in the direction of melt spinning, conductive/antistatic filament manufacturing, non-woven fabrics, etc., can solve the problems of small fiber drafting multiple, influence of composite material weight, and high material cost, and achieve Improve interlayer fracture toughness, lower conductive percolation threshold, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

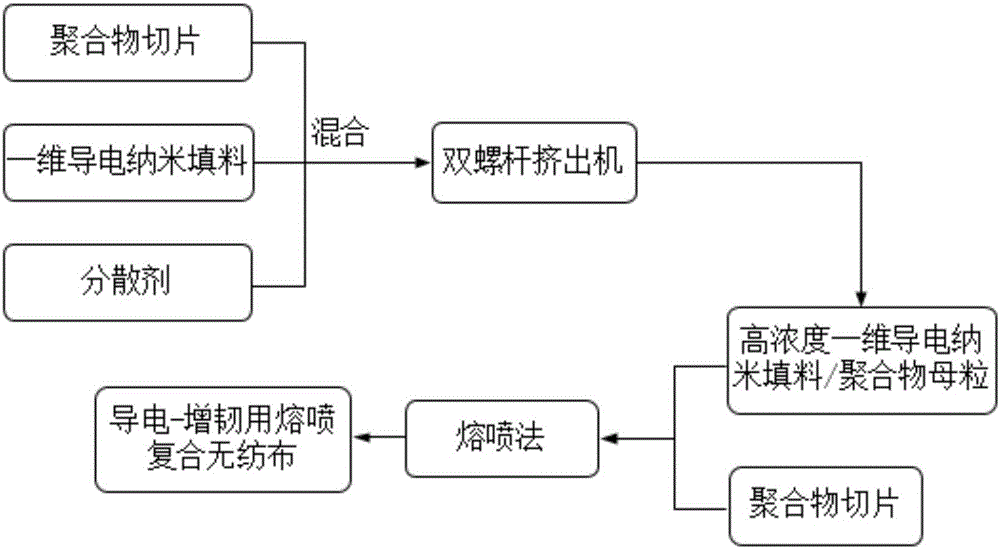

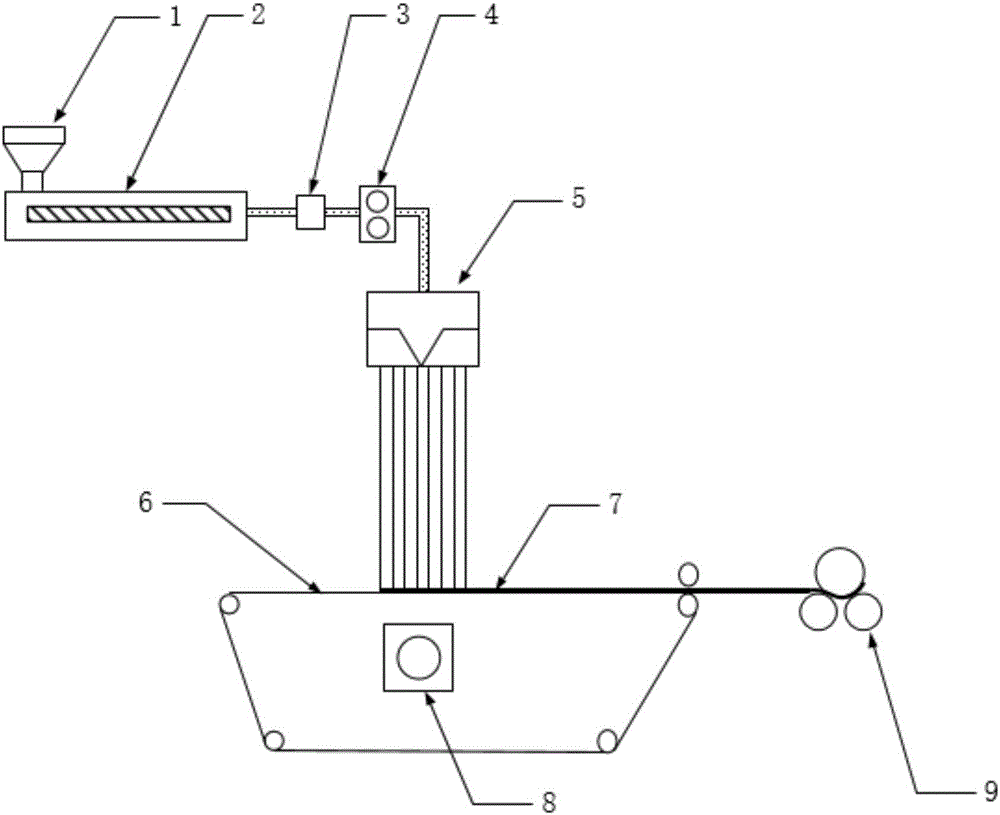

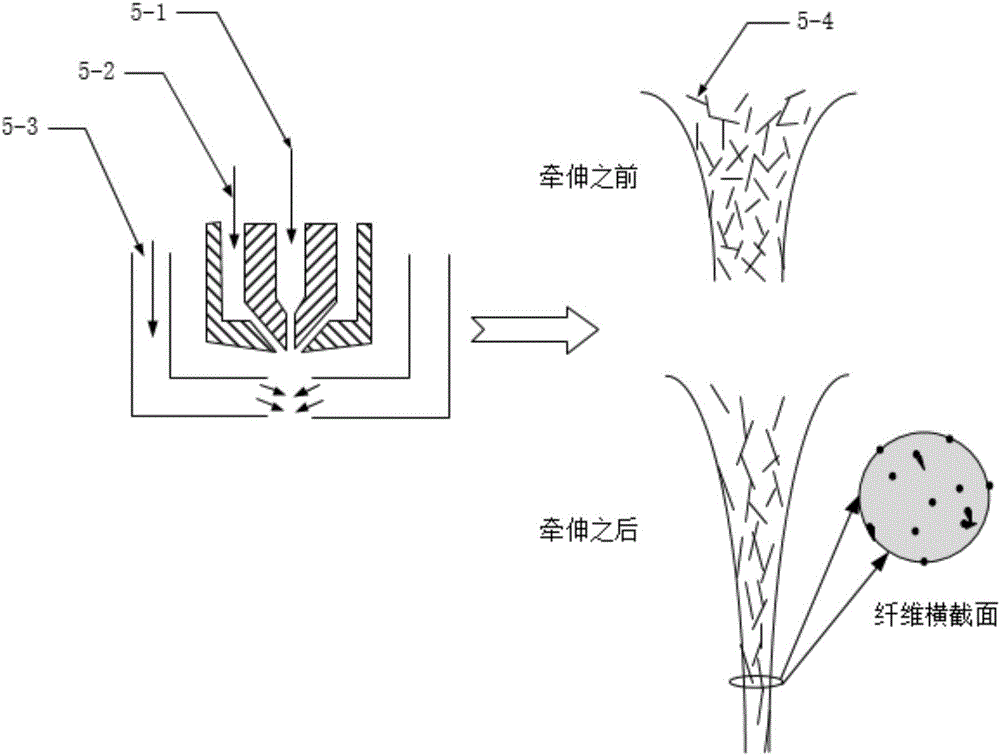

Method used

Image

Examples

Embodiment 1

[0055] Select 85 parts of polyphenylene sulfide chips, whose MFI is 460g / 10min, 10 parts of silver nanowires with a diameter of 40nm and an aspect ratio of 800, and 5 parts of polyacrylic acid sodium salt, and mix the three components by a high-speed mixer Extruded by a twin-screw extruder, cooled and molded to obtain a composite polyphenylene sulfide masterbatch containing high-concentration silver nanowires.

[0056] The specific preparation steps of this composite polyphenylene sulfide masterbatch containing high-concentration silver nanowires are as follows:

[0057] (1) Preliminarily dry polyphenylene sulfide slices and silver nanowires, and then add polyphenylene sulfide slices, silver nanowires and polyacrylic acid sodium salt into a high-speed mixer according to the mass ratio, and the mixing temperature is controlled at 120 ℃ to make it fully mixed.

[0058] (2) The above-mentioned mixture is fed from the hopper of the screw extruder, the screw speed is controlled at...

Embodiment 2

[0066] Select 85 parts of polyamide 6 chips, whose MFI is 1100g / 10min, 12 parts of carbon nanotubes with a diameter of 7nm and an aspect ratio of 1600:1, and 3 parts of polyvinyl alcohol, and mix the three components by a high-speed mixer Extruded by a twin-screw extruder, cooled and molded to obtain a composite polyamide 6 masterbatch containing high-concentration carbon nanotubes.

[0067] The specific preparation steps of this composite polyamide 6 masterbatch containing high-concentration carbon nanotubes are as follows:

[0068] (1) Dry polyamide 6 slices and carbon nanotubes in advance, and then add polyamide 6 slices, carbon nanotubes and polyvinyl alcohol into a high-speed mixer according to the mass ratio, and the mixing temperature is controlled at 100 ° C. It is well mixed and homogeneous.

[0069] (2) The above-mentioned mixture is fed from the hopper of the screw extruder, the screw speed is controlled at 65r / min, and the temperature of the melt at the extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com