Fine-grained high-strength tial alloy containing nanometer y2o3 and its preparation method

A nano-alloy technology, applied in the field of alloy material preparation, can solve the problems of large size difference and uneven distribution of Y-rich phase, etc., and achieve the effect of fine grain, good comprehensive mechanical properties, high-temperature deformation ability, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

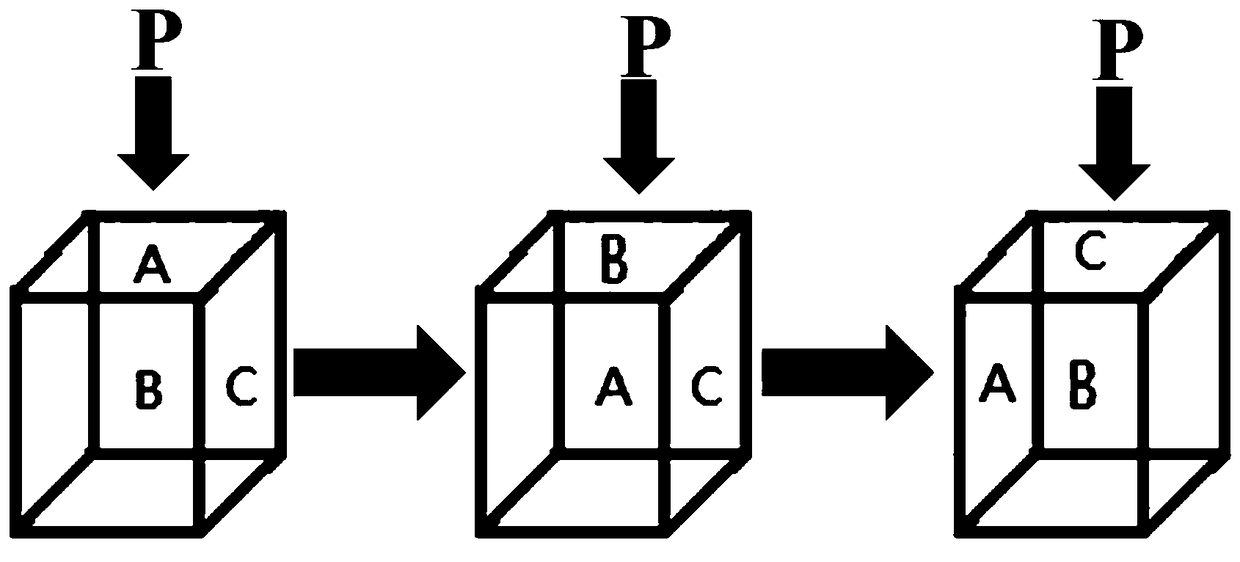

Method used

Image

Examples

Embodiment 1

[0042] Ti-45Al-3Mo-2V-0.2Y 2 o 3 The preparation method of fine-grained high-strength alloy is as follows:

[0043] (1) Weighing raw materials: 45% Al, 3% Mo, 2% V, 0.2% Y according to the atomic percentage of each element 2 o 3 , the balance being Ti and unavoidable impurities. Sponge titanium, pure aluminum, aluminum molybdenum alloy (Mo content is 52.21%), aluminum vanadium alloy (V content is 53.25%), nano Y 2 o 3 Powder (purity 99.99, particle size 100nm, such as figure 1 Shown) a total of 10000g as raw material.

[0044] (2) Melting ingots: Sponge titanium, high-purity aluminum, aluminum-molybdenum alloys, aluminum-vanadium alloys and nano-Y 2 o 3 The powder is added to the water-cooled copper crucible induction shell melting furnace for melting, and then poured into the ZrO preheated at 600 °C 2 In the ceramic mold, a rectangular ingot is obtained.

[0045] (3), billet pretreatment:

[0046] a. Remove the riser from the TiAl alloy ingot and perform hot isosta...

Embodiment 2

[0061] Ti-43Al-4Mo-2V-0.3Y 2 o 3 The preparation method of fine-grained high-strength TiAl alloy is as follows:

[0062] (1) Weighing raw materials: 43% Al, 4% Mo, 2% V, 0.3% Y according to the atomic percentage of each element 2 o 3 , the balance being Ti and unavoidable impurities. Sponge titanium, pure aluminum, aluminum molybdenum alloy (Mo content is 52.21%), aluminum vanadium alloy (V content is 53.25%), nano Y 2 o 3 Powder (purity 99.99, particle size 100nm) total 10000g as raw material;

[0063] (2) Melting ingots: Sponge titanium, high-purity aluminum, aluminum-molybdenum alloys, aluminum-vanadium alloys and nano-Y 2 o 3 The powder is added to the water-cooled copper crucible induction shell melting furnace for melting, and then poured into the ZrO preheated at 500 °C 2 In the ceramic mold, a rectangular ingot is obtained.

[0064] (3), billet pretreatment:

[0065] a. Remove the riser from the TiAl alloy ingot and perform hot isostatic pressing treatment. T...

Embodiment 3

[0080] Ti-44Al-1Mo-1V-0.1Y 2 o 3 The preparation method of fine-grained high-strength TiAl alloy is as follows:

[0081] (1) Weighing raw materials: 44% Al, 1% Mo, 1% V, 0.1% Y according to the atomic percentage of each element 2 o 3 , the balance being Ti and unavoidable impurities. Sponge titanium, pure aluminum, aluminum molybdenum alloy (Mo content is 52.21%), aluminum vanadium alloy (V content is 53.25%), nano Y 2 o 3 Powder (purity 99.99, particle size 100nm) total 10000g as raw material;

[0082] (2) Melting ingots: Sponge titanium, high-purity aluminum, aluminum-molybdenum alloys, aluminum-vanadium alloys and nano-Y 2 o 3 The powder is added to the water-cooled copper crucible induction shell melting furnace for melting, and then poured into the preheated Al 2 o 3 In the ceramic mold, a rectangular ingot is obtained.

[0083] (3), billet pretreatment:

[0084] a. Remove the riser from the TiAl alloy ingot and perform hot isostatic pressing treatment. The tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com