Methacrylic resin composition, method for producing same, molded body, film, and polarizing plate

A technology of methacrylic acid and methyl methacrylate, which is applied in the field of polarizing plates, can solve problems such as narrow molecular weight distribution, insufficient stretchability, and easy breakage, and achieve high transparency, small phase difference, and easy stretching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

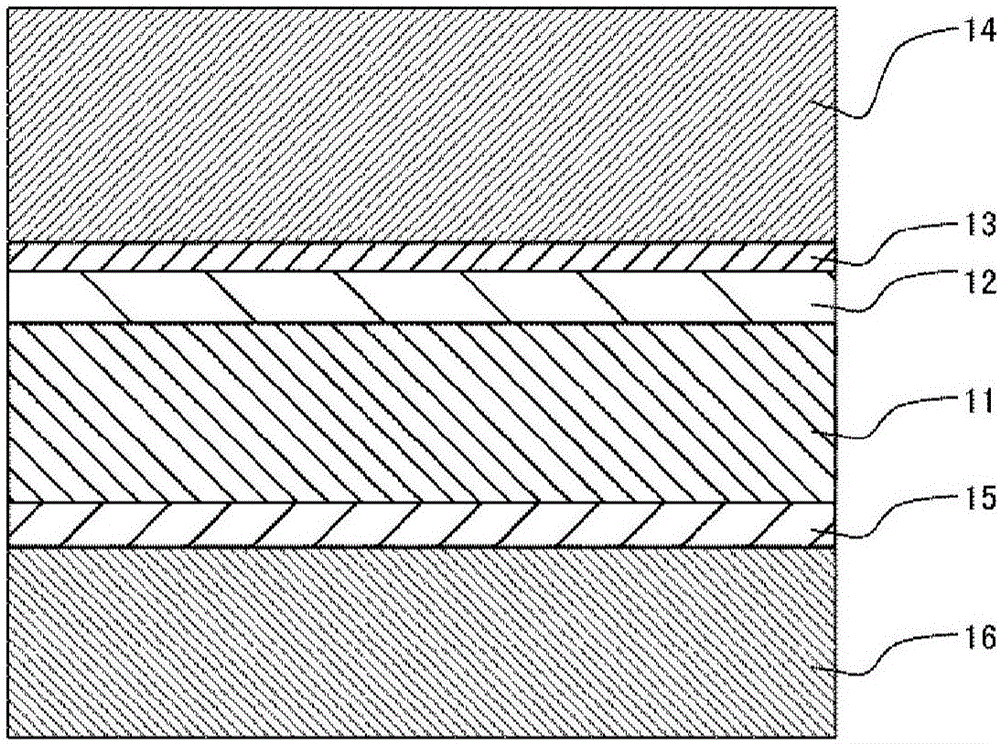

Image

Examples

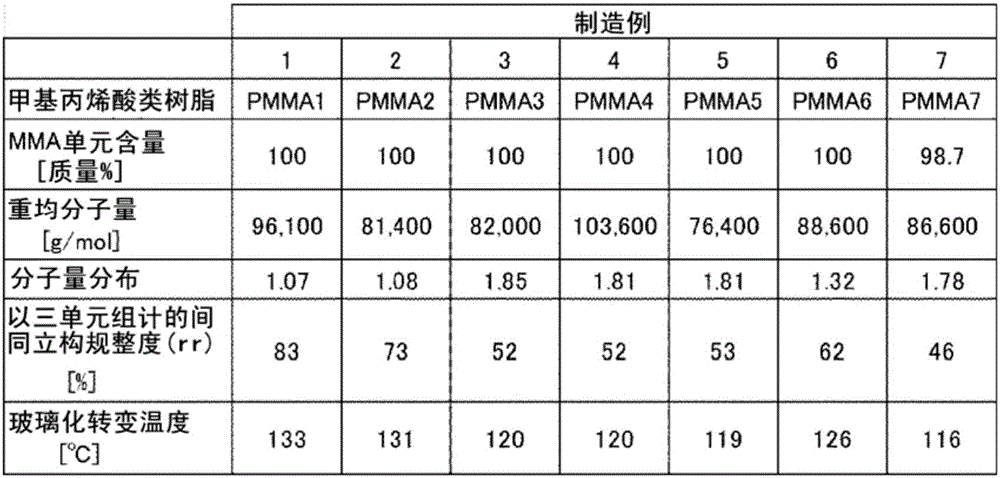

preparation example Construction

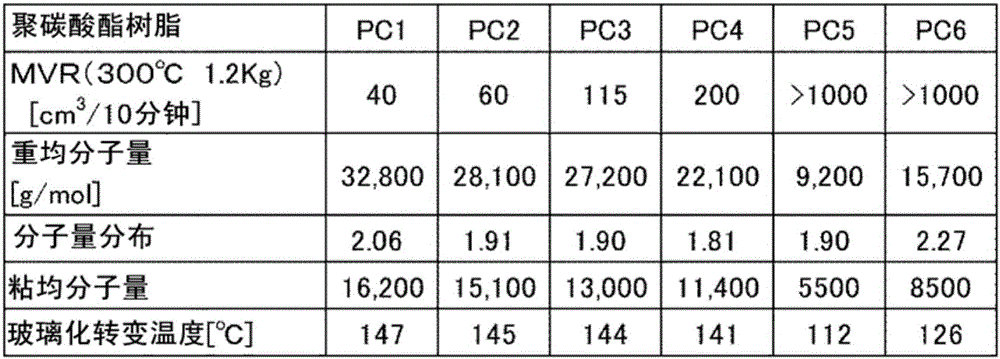

[0115] The method for producing the above-mentioned methacrylic resin composition is not particularly limited. For example, a method in which a monomer mixture containing methyl methacrylate is polymerized to produce a methacrylic resin in the presence of a polycarbonate resin, a method in which a methacrylic resin and a polycarbonate resin are melt-kneaded method etc. Among them, the melt-kneading method is preferable because the process is simple. During melt kneading, other polymers and additives can be mixed as needed, or methacrylic resin can be mixed with polycarbonate resin after mixing with other polymers and additives, or polycarbonate resin can be mixed with other The polymer and additives are mixed with the methacrylic resin. Kneading can be performed using known mixing or kneading devices such as kneading extruders, extruders, mixing rolls, and Banbury mixers, for example. Among them, a twin-screw extruder is preferable. The temperature at the time of mixing an...

Embodiment

[0160] Hereinafter, although an Example and a comparative example demonstrate this invention concretely, this invention is not limited to a following example. In addition, the measurement of a physical property value etc. was implemented by the following method.

[0161] (polymerization conversion rate)

[0162] Inert CAP 1 (df=0.4 μm, 0.25mmI.D.×60m) manufactured by GL Sciences is connected to the gas chromatograph GC-14A manufactured by Shimadzu Corporation as a chromatographic column, and the following conditions are set: The temperature is 180°C, the detector temperature is set to 180°C, the column temperature is raised from 60°C (hold for 5 minutes) to 200°C at a temperature increase rate of 10°C / min, and the measurement is carried out for 10 minutes, and the polymerization is calculated based on the result. Conversion rate.

[0163] (weight average molecular weight (Mw), molecular weight distribution (Mw / Mn))

[0164] Regarding the Mw and molecular weight distribution...

manufacture example 1

[0205] The inside of a 5-L glass reaction container equipped with a stirring blade and a three-way cock was replaced with nitrogen gas. At room temperature, 1600 g of toluene, 2.49 g (10.8 mmol) of 1,1,4,7,10,10-hexamethyltriethylenetetramine, and isobutylbis(2,6-ditertiary 53.5 g (30.9 mmol) of a toluene solution of butyl-4-methylphenoxy)aluminum, and a solution of sec-butyllithium with a concentration of 1.3 M (solvent: 95% by mass of cyclohexane, 5% by mass of n-hexane ) 6.17g (10.3mmol). While stirring, 550 g of methyl methacrylate purified by distillation was added dropwise thereto at -20° C. over 30 minutes. After completion of the dropwise addition, the mixture was stirred at -20°C for 180 minutes. The color of the solution changed from yellow to colorless. The polymerization conversion rate of methyl methacrylate at this point was 100%.

[0206] To the obtained solution, 1500 g of toluene was added and diluted. Next, this diluted solution was poured into 100 kg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com