Epoxy resin composition for electronic material, cured product thereof and electronic member

A technology of epoxy resin curing and epoxy resin, which is applied in the direction of epoxy resin glue, electric solid devices, electrical components, etc., can solve the problems of unspecified physical properties, records, and no thermal conductivity of epoxy resin, etc., and achieve excellent Effects of thermal conductivity, low thermal expansion, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0125] The present invention will be described more specifically based on Examples and Comparative Examples. In addition, the melt viscosity at 150° C., melting point, and GPC are measured on the following conditions.

[0126] 1) Melt viscosity at 150° C.: Measured with the following equipment in accordance with ASTM D4287.

[0127] Device name: MODEL CV-1S manufactured by Codex Co., Ltd.

[0128] 2) Melting point: Measured using a differential thermal gravimetric simultaneous measurement device (TG / DTA6200 manufactured by Hitachi High-Tech Science Co., Ltd.).

[0129] Measurement conditions

[0130] Measuring temperature: room temperature ~ 300 ℃

[0131] Measuring atmosphere: nitrogen

[0132] Heating rate: 10°C / min

[0133] 3) GPC: The measurement conditions are as follows.

[0134] Measuring device: "Shodex GPC-104" manufactured by Showa Denko Co., Ltd.,

[0135] Column: "Shodex KF-401HQ" manufactured by Showa Denko Co., Ltd.

[0136] + Manufactured by Showa Denko C...

Synthetic example 1

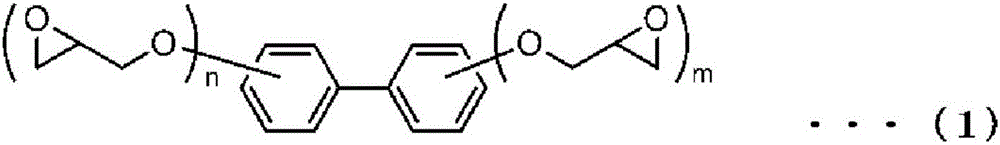

[0151] (Synthesis of 2,4,4'-Triglycidyloxybiphenyl)

[0152] In the flask equipped with a thermometer, a dropping funnel, a condenser, and a stirrer, nitrogen was purged, and 43 g of 2,4,4'-trihydroxybiphenyl, 295 g of epichlorohydrin, and 103 g of n-butanol were added to dissolve it. After heating up to 40 degreeC, after adding 53 g of 48 mass % sodium hydroxide aqueous solution over 8 hours, it heated up to 50 degreeC and made it react further for 1 hour. After the reaction was completed, 83 g of water was added and allowed to stand, and then the lower layer was discarded. Thereafter, unreacted epichlorohydrin was distilled off under reduced pressure at 150°C. To the crude epoxy resin thus obtained, 118 g of methyl isobutyl ketone was added and dissolved. Furthermore, 67 g of 10 mass % sodium hydroxide aqueous solutions were added to this solution, and it was made to react at 80 degreeC for 2 hours, and after that, washing with water was repeated 3 times until the pH of a ...

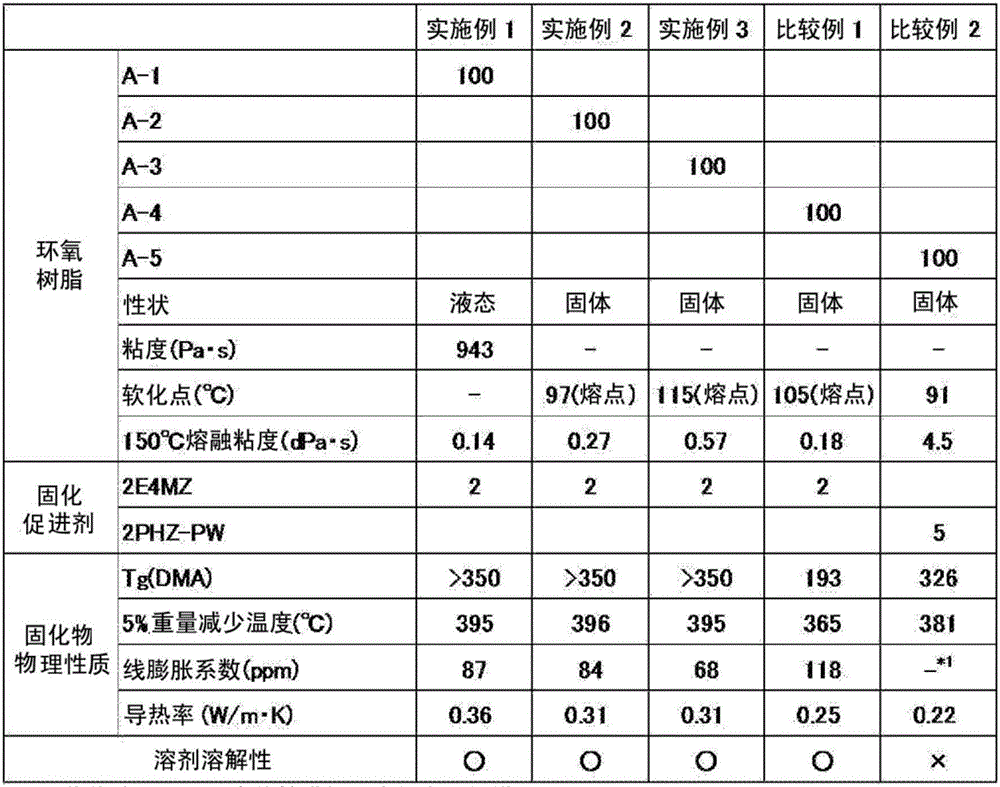

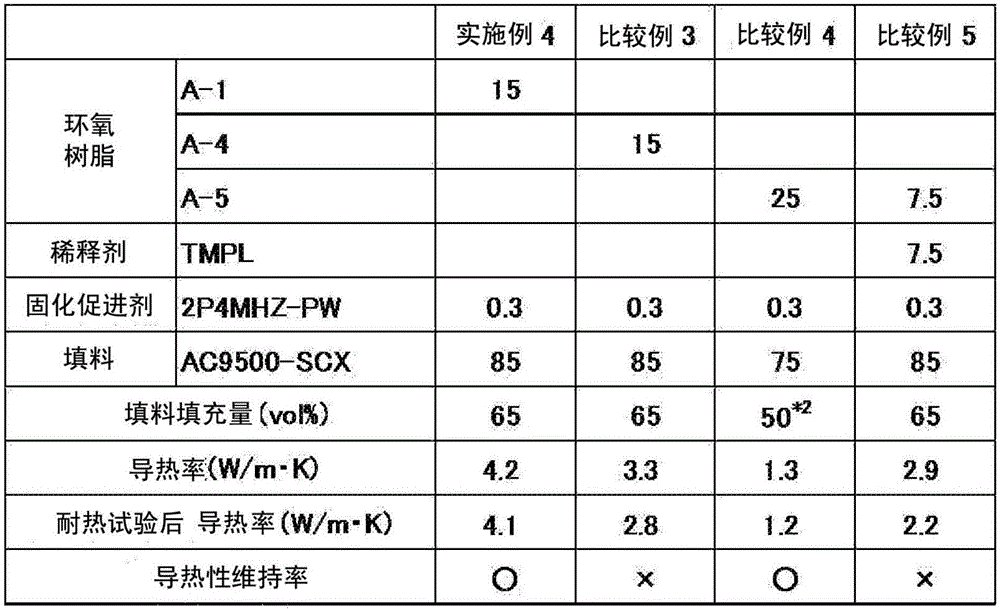

Embodiment 1~3 and comparative example 1~2

[0160] As the epoxy resins (A-1, A-2, A-3) of the present invention and comparative epoxy resins obtained in Synthesis Examples 1 to 3, 3,3',5,5'-tetramethyl- 4,4'-Biphenol-type epoxy resin (A-4), using imidazole (2E4MZ (manufactured by Shikoku Chemical Industry Co., Ltd.)) as a curing accelerator, was compounded with the composition shown in Table 1, respectively. The mixture was poured into a mold of 6 cm x 11 cm x 0.8 mm, pre-cured at a temperature of 110° C. for 2 hours, and then the molded product was taken out from the mold, and then cured at a temperature of 250° C. for 2 hours to produce a cured product. In addition, using a naphthalene-type tetrafunctional epoxy resin HP-4700 (manufactured by DIC Corporation) (A-5), and using imidazole (2PHZ-PW (manufactured by Shikoku Chemical Industry Co., Ltd.)) as a curing accelerator, the values listed in Table 1 were used. The composition shown was compounded, and the compounded material was poured into the mold of 6 cm x 11 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com