Modification method of lithium nickelate, cobaltate and manganate ternary material

A technology of nickel-cobalt lithium manganese oxide and ternary materials, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve problems affecting electrical properties, improve electronic conductivity, improve charge and discharge efficiency, and improve lithium Effect of ion diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention has no special limitation on the preparation method of the positive electrode, and the conventional preparation method of the NCM lithium ion battery positive electrode well known to those skilled in the art can be used. The modified NCM ternary positive electrode material and conductive agent prepared by the above method are preferred in the present invention. After mixing and stirring with a binder, a slurry is prepared, and the slurry is coated on an aluminum foil current collector, dried and cut to obtain a lithium-ion battery cathode material electrode sheet.

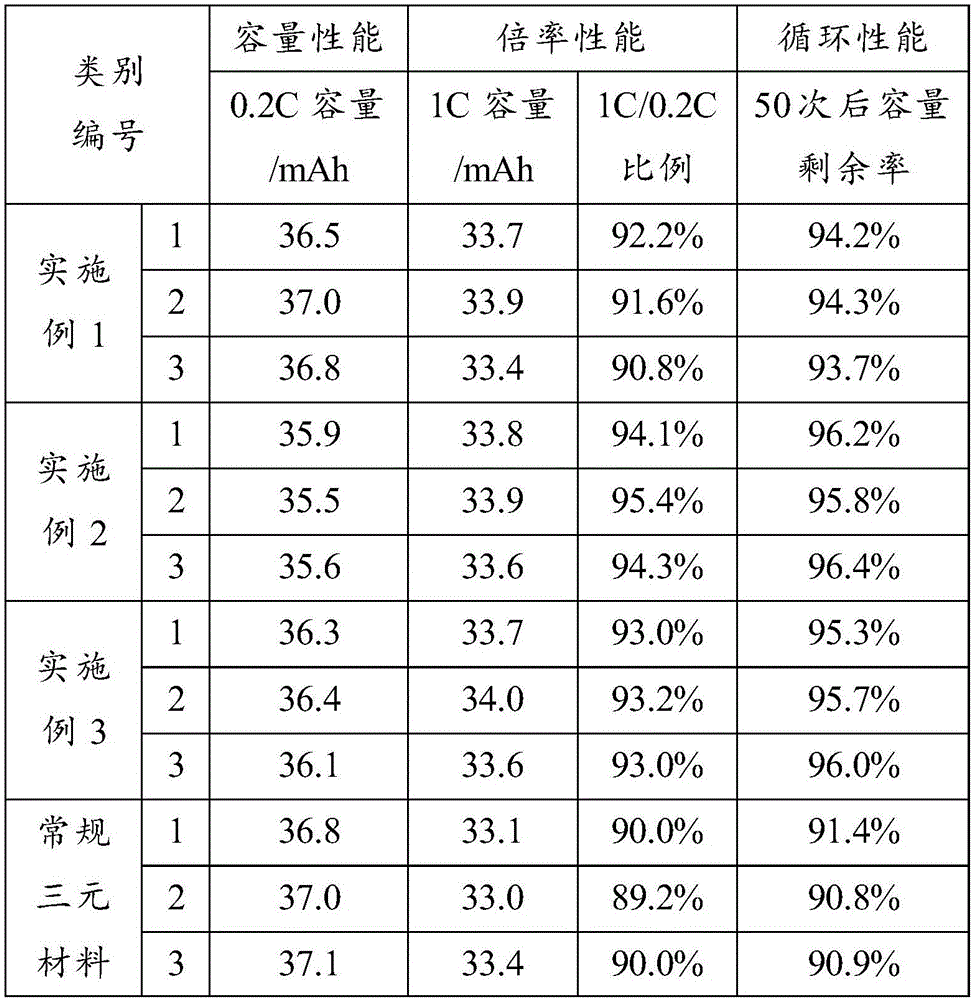

[0052] The above steps of the present invention deposit carbon on the surface of nickel-cobalt lithium manganese oxide ternary material by vapor deposition method, thereby realizing carbon coating. Carbon coating, especially preferably using carbon source gas and carbon dioxide as the gas source for chemical vapor deposition for carbon coating of ternary materials, by controlling the flo...

Embodiment 1

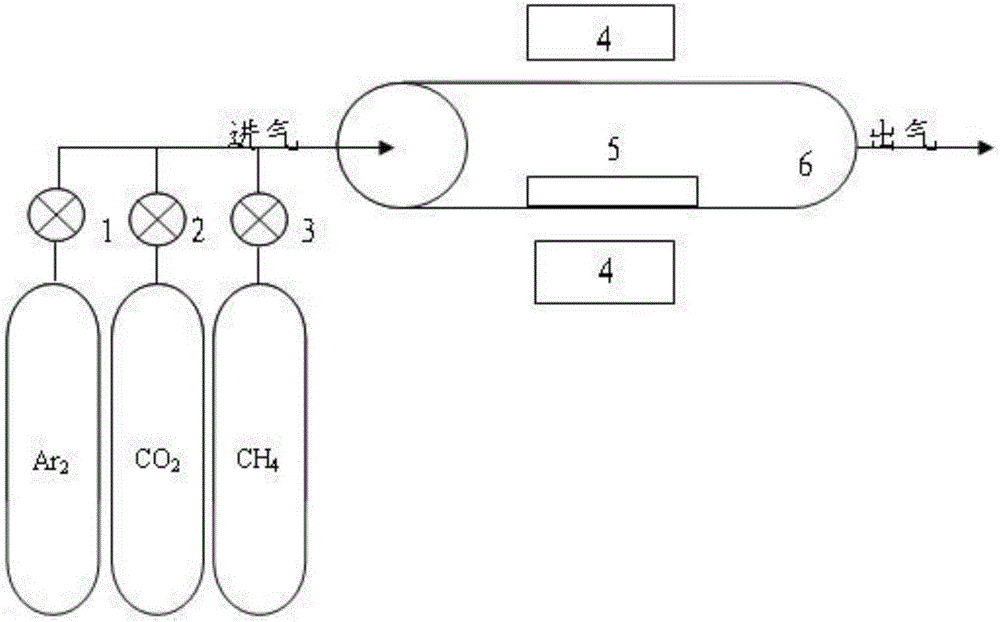

[0056] Weigh 5g of the ternary material and place it in the quartz boat 5, then put the quartz boat into the middle of a horizontally placed quartz tube, and then send the quartz tube into the high temperature zone of the heating furnace.

[0057] Open the gas valve of the argon gas cylinder at 1, adjust the gas flow rate to 50 mL / min, and ventilate for 30 min to exhaust the air in the quartz tube 6. Then close the gas valve of the argon cylinder at 1, and open the carbon dioxide (CO2) at 2 2 ) cylinders and methane (CH 4 ) of the gas cylinder, the air flow rate is adjusted to 50mL / min, and carbon dioxide and methane are simultaneously introduced into the quartz tube.

[0058] Turn on the heating furnace 4, set the heating rate to 20°C / min, raise the quartz tube from room temperature to 1000°C, and keep it at 1000°C for 15 minutes to allow methane to crack and form a carbon layer to deposit on the surface of the ternary material.

[0059] After the reaction is over, stop hea...

Embodiment 2

[0064] Weigh 5g of the ternary material and place it in the quartz boat 5, then put the quartz boat into the middle of a horizontally placed quartz tube, and then send the quartz tube into the high temperature zone of the heating furnace.

[0065] Open the gas valve of the argon gas cylinder at 1, adjust the gas flow rate to 50 mL / min, and ventilate for 30 min to exhaust the air in the quartz tube 6. Then close the gas valve of the argon gas cylinder at 1 place, open the gas valves of the 2 carbon dioxide gas cylinders and the 3 methane gas cylinders, adjust the gas flow to 50mL / min and 80mL / min respectively, and simultaneously feed carbon dioxide and gas into the quartz tube. methane.

[0066]Turn on the heating furnace 4, set the heating rate to 25°C / min, raise the quartz tube from room temperature to 1100°C, and keep it at 1100°C for 20 minutes to allow methane to crack and form a carbon layer to deposit on the surface of the ternary material.

[0067] After the reaction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com