Cooling bed lifting hydraulic synchronous control device

A hydraulic synchronization and control device technology, which is applied in the direction of fluid pressure actuators, cooling beds, metal rolling, etc., can solve the problems of reduced motor life, unstable cooling bed movement, and large pressure drop of synchronous motors, etc., to achieve stable Start and stop, low cleanliness requirements, and small pressure drop at the valve port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

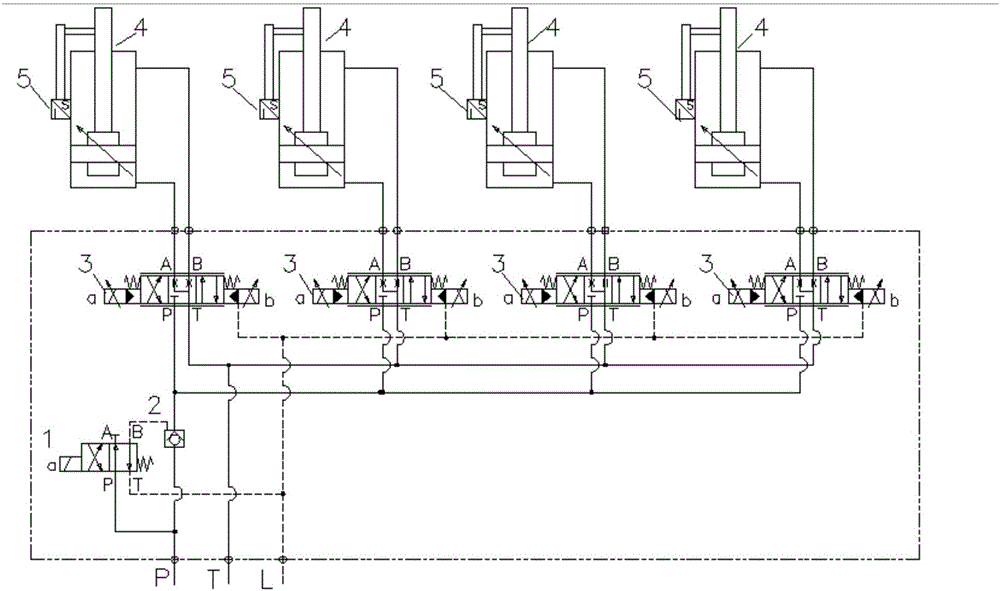

[0019] see figure 1 , a cooling bed lifting hydraulic synchronous control device, including a number of proportional directional valves 3 arranged in parallel on the hydraulic valve table next to the cooling bed, and an electromagnetic reversing valve 1 and Hydraulic control check valve 2, servo hydraulic cylinder 4 is also connected to the oil outlet pipeline of each proportional directional valve 3, displacement sensor 5 is set on the servo hydraulic cylinder 4 as an external displacement sensor, displacement sensor 5 is also connected with proportional directional valve 3 connected, the proportional directional valve 3 and the displacement sensor 5 form a position closed loop.

[0020] Among them, the electromagnetic reversing valve 1 controls the oil supply of each proportional direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com