Preparation method and application of efficient photoelectrocatalytic water-decomposition oxygen-production electrode

A photoelectric catalysis, oxygen electrode technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of unobtainable performance, excellent photoelectrochemical water splitting composite electrodes, high cost and scarcity of precious metals that limit large-scale applications, etc. Good electrocatalytic activity, effective separation, good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

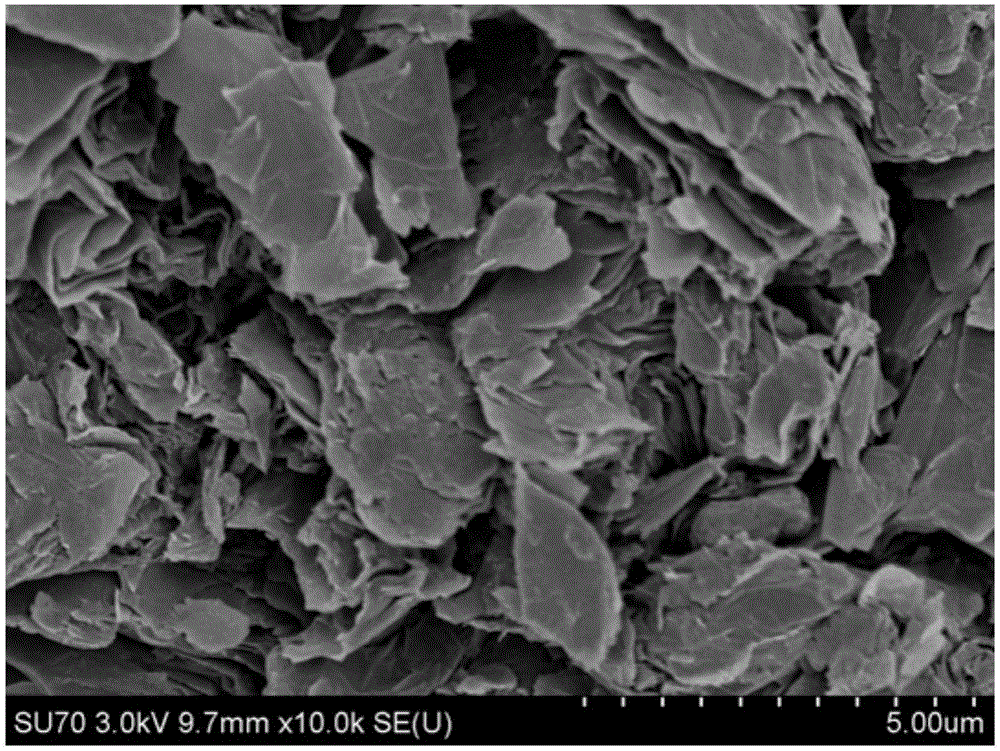

[0038] The geometric area is 0.2826 cm 2 Graphite flakes (0.6 cm in diameter and 0.1 cm in thickness) were ultrasonically cleaned with deionized water, absolute ethanol and acetone for 30 minutes to remove organic matter on the surface. Placed in an oven, dried at 40°C for 12 hours, ready for use, the morphology picture of the blank graphite sheet obtained by scanning electron microscope is as follows: Picture 1-1 shown. Fix the dried graphite sheet on the bottom of the electrode rod (polytetrafluoroethylene shell with conductive copper rod inside) with conductive silver glue, as an electrode.

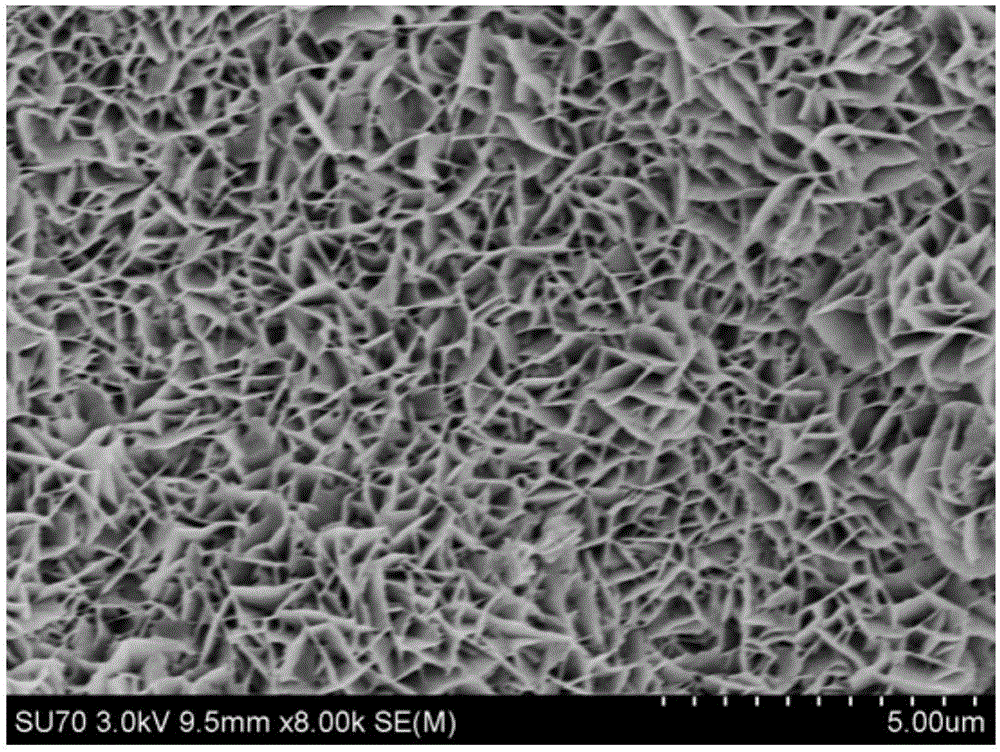

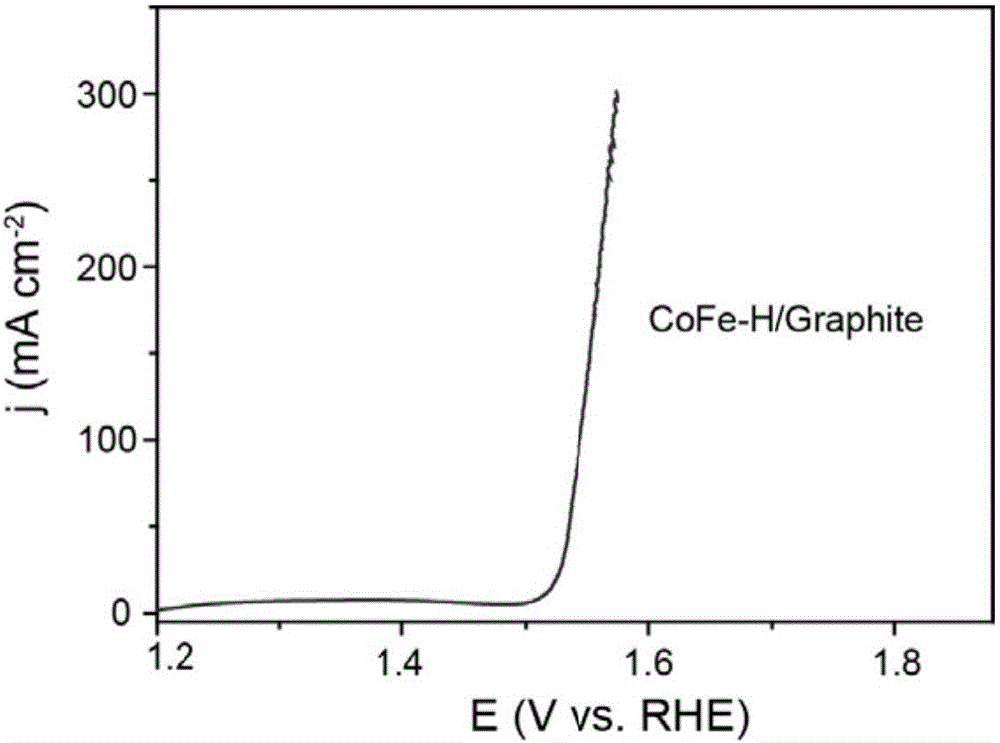

[0039] Graphite electrode was used as working electrode, stone grinding rod was used as counter electrode, and mercurous sulfate electrode was used as reference electrode. The electrodeposition solution is composed of cobalt nitrate and ferric nitrate, both of which have a concentration of 6 mmol / L. The volume of the electrodeposition solution was 70 mL. Before the start of the elec...

Embodiment 2

[0042] Referring to the electrodeposition method of Example 1, ITO conductive glass (5cm*2cm) was used as the working electrode, Pt sheet (1cm*1cm) was used as the counter electrode, and the mercurous sulfate electrode was used as the reference electrode. The conditions of the electrodeposition solution were the same as in Example 1. The same, different deposition time (0-300s), in which the area of ITO immersion electrolyte is 2cm*2cm. The prepared CoFe-H / ITO electrode was then rinsed with a large amount of ultrapure water, and placed in a vacuum oven at 30°C for 12 hours to dry.

[0043] The prepared CoFe-H / ITO samples with different deposition times were measured with a UV-spectrophotometer (UV-3150 UV-Vis) for their light transmittance, and the scanning range was 300-800nm. The transmittance data of samples with different deposition times are as follows: figure 2 . As the deposition time prolongs, the color of the sample gradually becomes darker and the light transmitt...

Embodiment 3

[0045] Firstly, the BiVO 4 Nanoporous film deposited onto the surface of fluorine-doped conductive glass to fabricate BiVO 4 / FTO photoelectrode, typical BiVO 4 The scanning electron microscope picture of the three-dimensional porous nano-membrane electrode is as follows: Figure 3-1 ;

[0046] The two-step method of electrodeposition and calcination is as follows: prepare a three-dimensional porous bismuth vanadate nanofilm substrate on the surface of FTO: first prepare a molar concentration of 0.04mol / L Bi(NO 3 ) 3 and 0.4 mol / L KI mixed solution 50mL, then use concentrated nitric acid to adjust the pH of the solution to about 1.7, then prepare 20mL p-benzoquinone ethanol solution with a molar concentration of 0.23mol / L, and finally mix the above two solutions and stir vigorously for 5 minute. Then, a three-electrode system was used for constant potential deposition, with a platinum sheet as the counter electrode, Ag / AgCl (saturated potassium chloride solution) as the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com