A low-cost and high-performance wc-fe-ni-co-cr cemented carbide roller ring

A technology of wc-fe-ni-co-cr and cemented carbide is applied in the field of low-cost and high-performance WC-Fe-Ni-Co-Cr cemented carbide roll rings, which can solve the problems of poor performance, low life, hard The high cost of alloy roll rings has achieved the effect of reducing production costs and saving cobalt resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

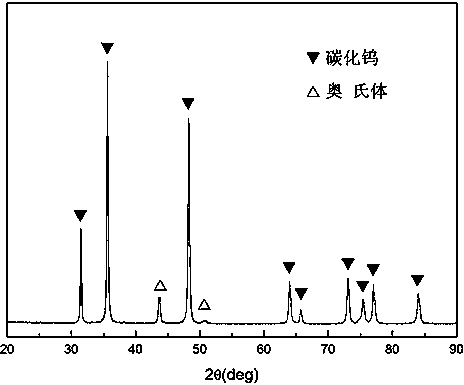

Embodiment 1

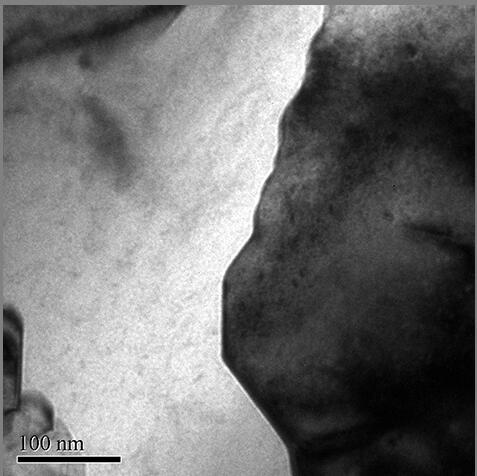

[0031] A low-cost and high-performance WC-Fe-Ni-Co-Cr cemented carbide roll ring, the proportion of Fe in the binder is controlled at 42.5wt.%. The specific alloy composition is: 80wt.% WC powder (average grain size 6-15μm), 8.5wt.% Fe powder (0.5-2.0μm particle size), 8.2wt.% Ni powder (0.5-2.0μm particle size ), 2.7 wt.% Co powder (particle size 1.0-2.0μm), 0.6wt.% Cr powder (particle size 1.0-2.0μm). The above powder is ball milled and mixed according to the requirements, using YG8 cemented carbide balls with a diameter of 6~12mm as the grinding body, the mass ratio of the ball to material is 4:1, using gasoline as the ball milling medium, and adding 200~ Add in a proportion of 400ml, the ball milling speed is 60~250rpm, ball mill on a roller ball mill for 16h, after ball milling and mixing, the slurry is dried at 80°C in a vacuum environment for 4h. Add 0.8wt.% synthetic rubber as a molding agent, press it into a cemented carbide roller ring compact under a pressure of 12...

Embodiment 2

[0033]A low-cost and high-performance WC-Fe-Ni-Co-Cr cemented carbide roller ring, the proportion of Fe in the binder is controlled at 57.5wt.%. The specific alloy composition is: 80wt.% WC powder (average grain size 6-15μm), 11.5wt.% Fe powder (particle size 0.5-2.0μm), 5.9wt.% Ni powder (particle size 0.5-2.0μm) ), 2.1 wt.% Co powder (1.0-2.0μm particle size), 0.5wt.% Cr powder (1.0-2.0μm particle size). The above powder is ball milled and mixed according to the requirements, using YG8 cemented carbide balls with a diameter of 6~12mm as the grinding body, the mass ratio of the ball to material is 4:1, using gasoline as the ball milling medium, and adding 200~ Add in a proportion of 400ml, the ball milling speed is 60~250rpm, ball mill on a roller ball mill for 16h, after ball milling and mixing, the slurry is dried at 80°C in a vacuum environment for 4h. Add 0.8wt.% synthetic rubber as a molding agent, press it into a cemented carbide roller ring compact under a pressure of...

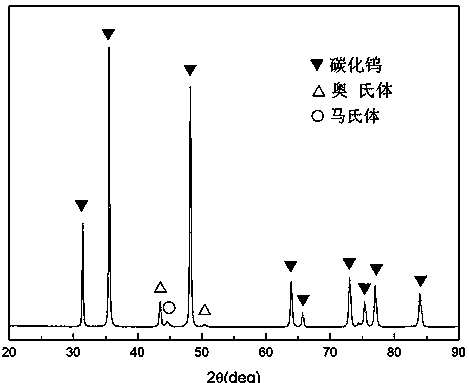

Embodiment 3

[0035] A low-cost and high-performance WC-Fe-Ni-Co-Cr cemented carbide roll ring, the proportion of Fe in the binder is controlled at 71.5wt.%. The specific alloy composition is: 80wt.% WC powder (average grain size 6-15μm), 14.3wt.% Fe powder (particle size 0.5-2.0μm), 3.2wt.% Ni powder (particle size 0.5-2.0μm) ), 1.2 wt.% Co powder (1.0-2.0μm particle size), 0.6wt.% Cr powder (1.0-2.0μm particle size). The above powder is ball milled and mixed according to the requirements, using YG8 cemented carbide balls with a diameter of 6~12mm as the grinding body, the mass ratio of the ball to material is 4:1, using gasoline as the ball milling medium, and adding 200~ Add in a proportion of 400ml, the ball milling speed is 60~250rpm, ball mill on a roller ball mill for 16h, after ball milling and mixing, the slurry is dried at 80°C in a vacuum environment for 4h. Add 0.8wt.% synthetic rubber as a molding agent, press it into a cemented carbide roller ring compact under a pressure of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com