A kind of kerosene co-refining method and its device

A technology of co-refining and kerosene, which is applied in the petroleum industry, processing hydrocarbon oil, hydrotreating process, etc., can solve the problems of reducing the ability to process coal, reducing equipment utilization, and having a great influence on the co-processing results of heavy oil and kerosene , to avoid secondary cracking and improve hydrogen supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

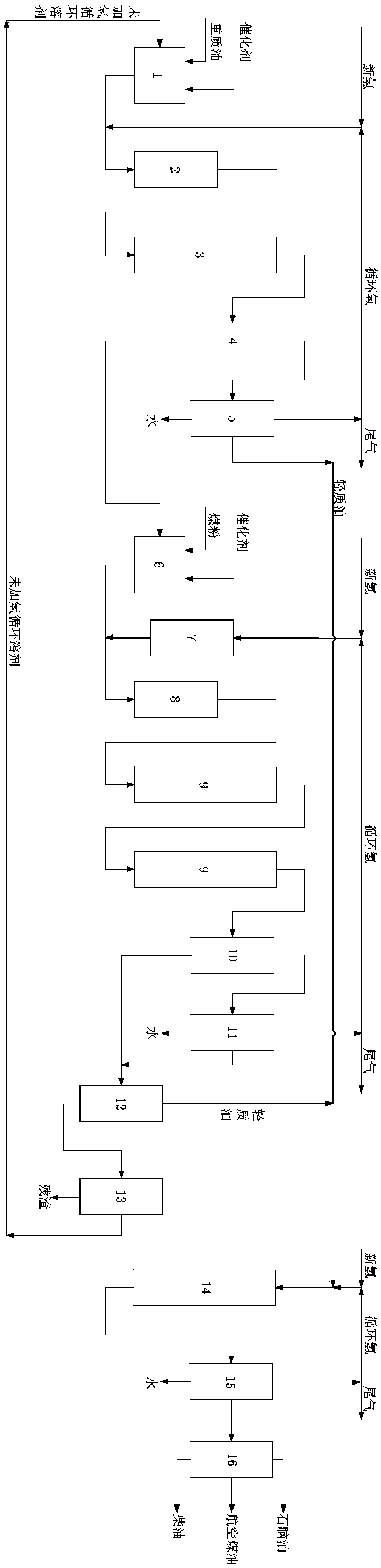

[0049] This embodiment provides a kerosene co-refining device and a co-refining method thereof.

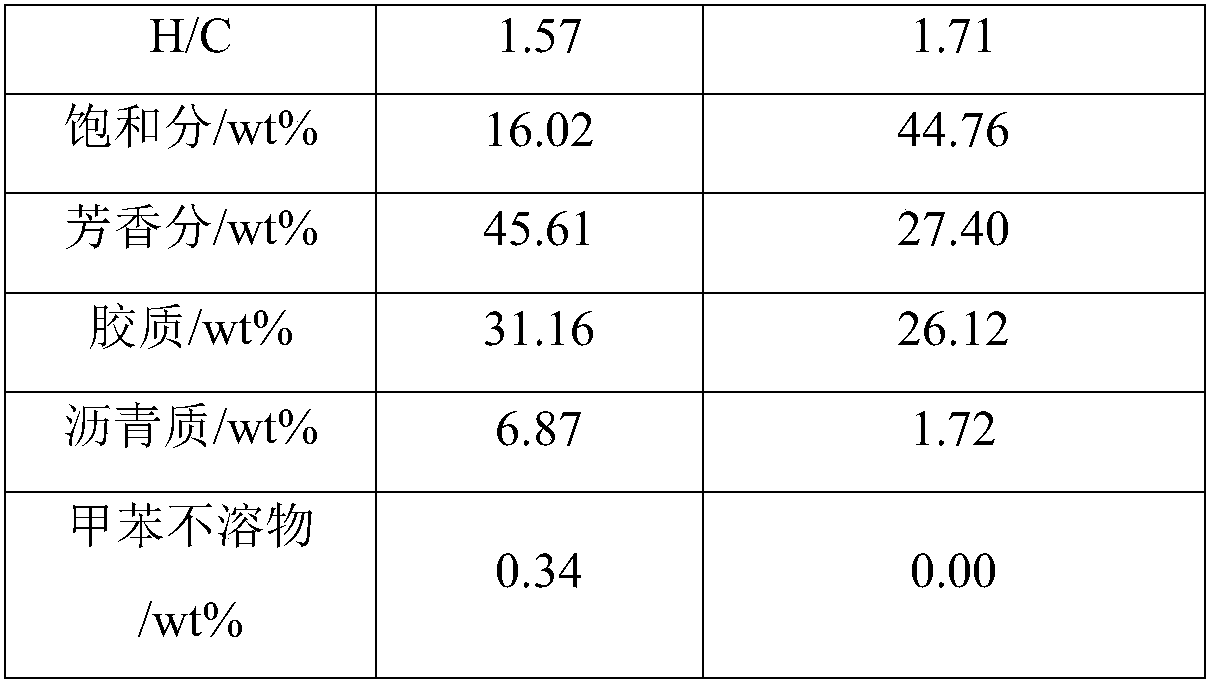

[0050] The oil component in this example is vacuum residue, and its properties are shown in Table 1; the coal component in this example is low-priced bituminous coal in Xinjiang, and its properties are shown in Table 2.

[0051] Bituminous coal pretreatment: The coal is crushed to below 200 mesh, and then dried to reduce its moisture content to <1%.

[0052] Slurry pretreatment: first, carry out separate autoclave hydrogenation of the vacuum residue, the addition of vacuum residue is 45g, the addition of Fe-based catalyst is 0.7%, hydrogenation is carried out at an initial hydrogen pressure of 7Mpa and a reaction temperature of 420°C. Hydrogen reaction, reaction time 1h, 43.2g of liquid phase product was obtained, the liquid phase product was subjected to distillation and cutting, and 37.3g of >350°C fraction product was obtained.

[0053] Co-refining of kerosene: make a 40% oil-...

Embodiment 2

[0056] This embodiment provides a kerosene co-refining device and a co-refining method thereof. The kerosene co-refining device provided in this embodiment is as figure 1 shown.

[0057] The oil component in this example is vacuum residue, and its properties are shown in Table 1; the coal component in this example is low-priced bituminous coal in Xinjiang, and its properties are shown in Table 2.

[0058] The coal is crushed to less than 3mm by a crusher, then dried to reduce its moisture content to less than 3%, and then ground to less than 100 mesh by a ball mill for use. In the heavy oil pretreatment process, the reaction temperature is 410°C, the reaction pressure is 16MPa, the gas-liquid ratio is 1000, the feed rate of atmospheric residual oil is 8kg / h, and the catalyst addition amount is 1%. After hydrotreating, it is obtained The light distillate oil is 2.8kg / h, and the heavy distillate oil is 5.6kg / h. Heavy distillate oil and coal powder were prepared into oil-coal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com