Zirconium carbide-zirconium diboride complex-phase ceramic powder synthesized through thermal explosion and preparation method thereof

A technology of zirconium diboride and composite ceramics, which is applied in the field of boride composite ceramic powder materials and transition metal carbides, can solve problems such as low activity, uneven carbonization, and large particle size of zirconium diboride powder, and achieve The effect of simple process, rapid response and high degree of product compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Zr-B 4 C system

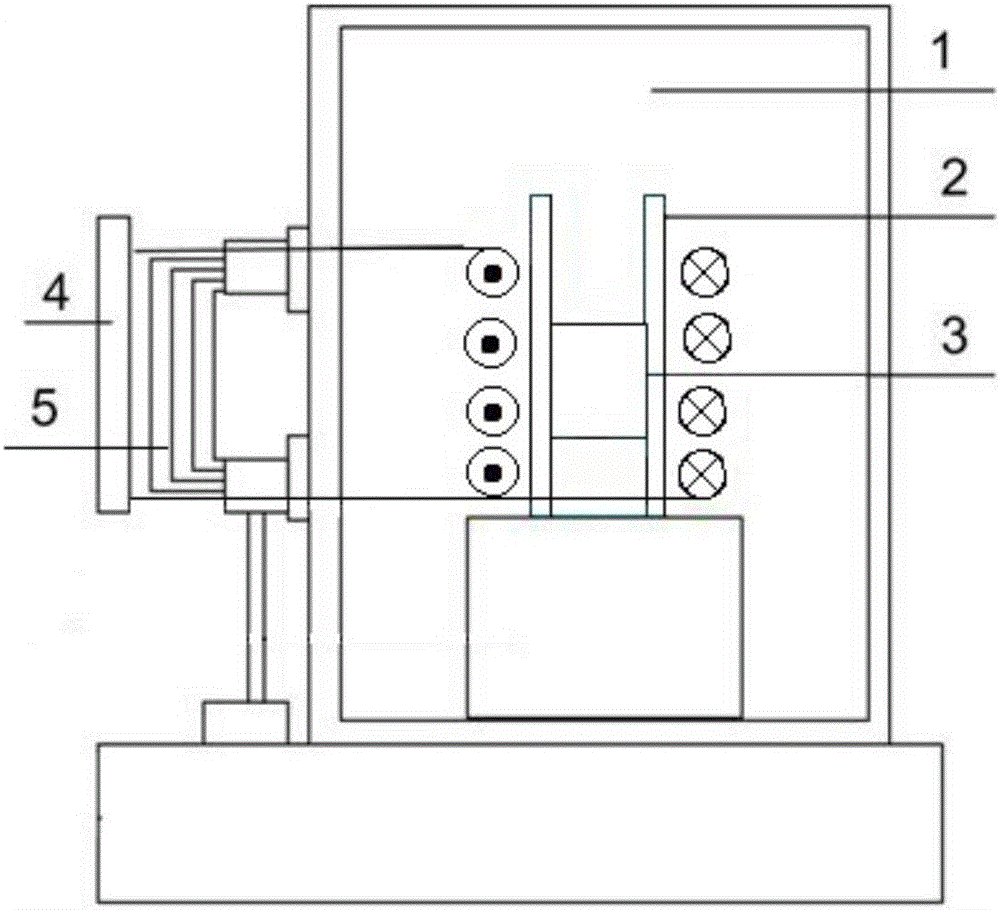

[0031] For Zr-B 4 System C consists of the following components by mole percentage: Zr powder 75mol.%, B 4C powder 25mol.%, the molar ratio of the two is 3:1, and the sum of the molar percentages is 100mol.%. Zr powder and B 4 Weigh 16.0 grams of powder C according to a molar ratio of 3:1 and mix them evenly, then press and form a cylindrical green body under a pressure of 35-40 MPa, with a diameter of 20 mm, a thickness of 15 mm, and a relative density of 65 ± 3%. Then put the compact 3 into the graphite crucible 2, and then place one piece in the reaction chamber 1 of the induction furnace, first evacuate it and then fill it with Ar gas for protection, switch on the SIT high-frequency power supply 4, within 20-25s Adjust the voltage applied by the high-frequency induction furnace to increase from 0 to 65 volts (the current will increase accordingly from 0 to 45 amps). At this time, the overall reaction of the agglomerate will be ignite...

Embodiment 2

[0033] Embodiment 2: 10wt.% Al-Zr-B4C system

[0034] For 10wt.% Al-Zr-B 4 C system, the raw materials are composed of the following components according to mass percentage: Al powder 10wt.%, Zr powder and B 4 A total of 90wt.% of C powder, of which Zr powder, B 4 C powder according to Zr:B 4 The molar ratio of C=3:1 is prepared, and the sum of the mass percentages of the three components is 100%. Al powder, Zr powder and B 4 C powder is weighed according to this component ratio, in which Zr powder and B 4 The molar ratio of C powder is 3:1, the total weight is 15.7 grams and mixed evenly, and the cylindrical green body is pressed under a pressure of 35-40 MPa, with a diameter of 20 mm, a thickness of 15 mm, and a relative density of 65 ± 3%. Then put the compact 3 into the graphite crucible 2, and then place one piece in the reaction chamber 1 of the induction furnace, first evacuate it and then fill it with Ar gas for protection, switch on the SIT high-frequency power s...

Embodiment 3

[0036] Embodiment 3: 20wt.% Al-Zr-B4C system

[0037] For 20wt.% Al-Zr-B 4 C system, the raw materials are composed of the following components according to mass percentage: Al powder 20wt.%, Zr powder and B 4 A total of 80wt.% of C powder, of which Zr powder, B 4 C powder according to Zr:B 4 The molar ratio of C=3:1 is prepared, and the sum of the mass percentages of the three components is 100%. Al powder, Zr powder and B 4 C powder is weighed according to this component ratio, in which Zr powder and B 4 The molar ratio of C powder is 3:1, the total weight is 15.4 grams and mixed evenly, and the cylindrical green body is pressed under a pressure of 35-40 MPa, with a diameter of 20 mm, a thickness of 15 mm, and a relative density of 65 ± 3%. Then put the compact 3 into the graphite crucible 2, and then place one piece in the reaction chamber 1 of the induction furnace, first evacuate it and then fill it with Ar gas for protection, switch on the SIT high-frequency power s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com