Nanosilicon dioxide pellet and preparing method thereof

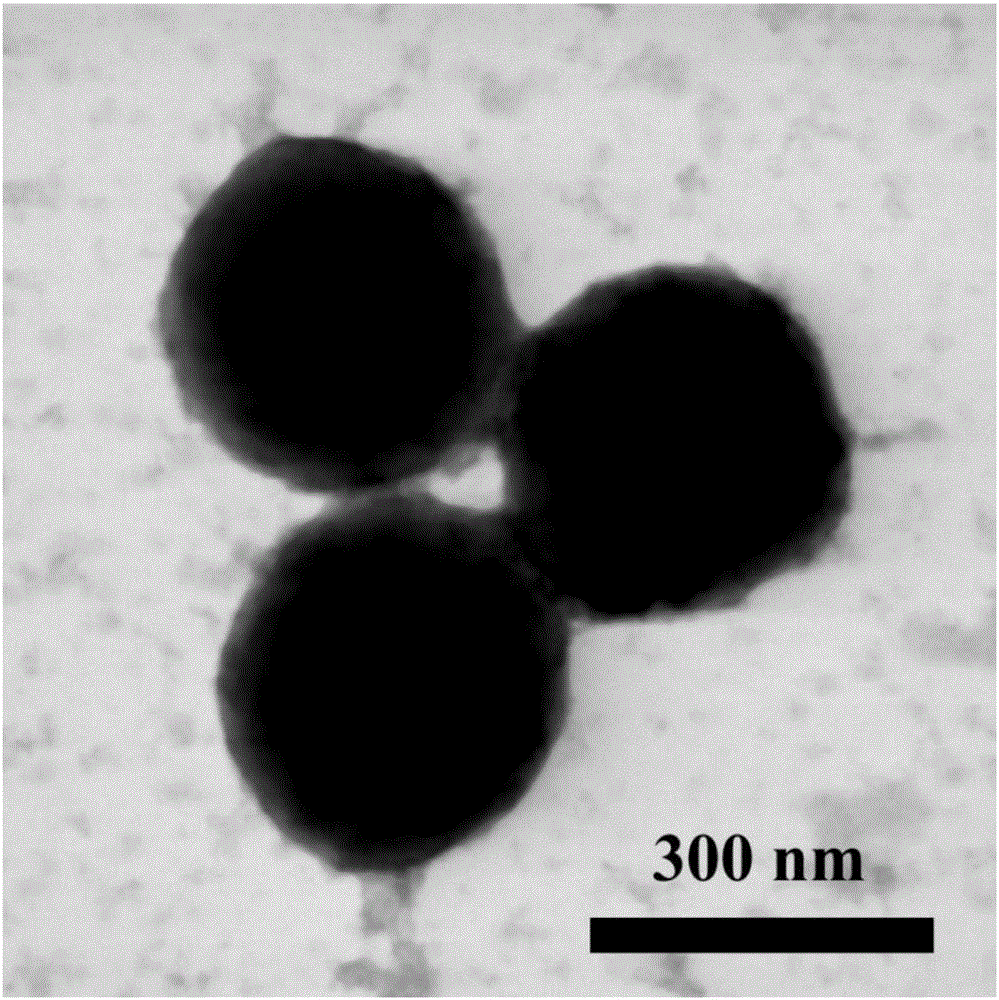

A technology of nano-silica and silicon dioxide, which is applied in the preparation of microspheres, silicon dioxide, silicon oxide, etc., can solve the problems of not being able to obtain an ideal core-shell structure, limiting silica deposition, and polymer agglomeration. Achieve the effects of controllable shell thickness and cavity ratio, good monodispersity and high hollow ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method for nano silicon dioxide microspheres, comprising the following steps:

[0046] 1) uniformly dispersing the initiator and the polyalkoxysiloxane in the nuclei forming material to obtain an organic phase;

[0047] 2) adding the organic phase to the water phase to obtain a mixed system of two-phase separation; stirring and heating the mixed system under the condition of nitrogen protection, and obtaining an emulsion containing nanocomposite microspheres after the reaction;

[0048] 3) removing the solvent in the emulsion, retaining the nanocomposite microspheres, and drying the nanocomposite microspheres to obtain nano silica microspheres comprising a silica shell and a polymer core ;

[0049] 4) removing the polymer core body in the nano-silica microspheres to obtain nano-silica hollow microspheres

[0050] Wherein, in step 1), firstly, the initiator is uniformly dispersed in the polymer forming material, then polyalkoxysiloxane is added, mixed uni...

Embodiment 1

[0053] A preparation method for nano silicon dioxide microspheres, comprising the following steps:

[0054] (1) Evenly disperse 0.012 grams of oil-soluble initiator azobisisobutyronitrile (AIBN) in 1.2 grams of methyl methacrylate, add 1.2 grams of polyethoxysiloxane, and ultrasonically disperse to obtain a uniform organic Mutually;

[0055] (2) The above organic phase was added to 30 g of water (pH=7), and the mass of the organic phase was 8% of the mass of the aqueous phase. Stir and heat the two-phase mixture to 65°C under nitrogen protection, and react for 24 hours. After the reaction, a polymethyl methacrylate / silica nanocomposite microsphere emulsion with a core-shell structure is obtained;

[0056] (3) Centrifuge the above emulsion at a speed of 8000 rpm for 10 minutes, pour off the supernatant, redisperse the white solid object in the lower layer in water, ultrasonically wash, then centrifuge, wash again, and finally dry to obtain dried Polymethyl methacrylate / silica...

Embodiment 2

[0060] The difference between embodiment 2 and embodiment 1 is that the amount of azobisisobutyronitrile (AIBN) in step (1) is reduced to 0.01 gram, and 1.2 gram of methyl methacrylate monomer is changed into 0.8 gram of methyl methacrylate A mixture of methyl acrylate monomer and 0.4 gram of hexadecane; the heating temperature in step (3) was raised to 70°C.

[0061] Finally, nanocomposite microspheres with a three-layer structure (silica / polymethyl methacrylate / hexadecane) are obtained. The size of the microspheres is about 400nm, and the outermost layer of the microspheres is a continuous and uniform silica layer. , the middle layer is a polymethyl methacrylate layer, and the inner layer is hexadecane. After the hexadecane is released, it will enter the hollow nanocomposite microspheres. After removing the polymer core, the cavity of the hollow microspheres is further enlarged, but still maintains a complete spherical shape, showing good thermal and mechanical stability. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com