Active optical phased array photon integration chip and manufacturing method thereof

A photon integration, phased array technology, applied in lasers, laser devices, phonon exciters, etc., can solve the problems of difficult injection locking of injected optical power, and no simultaneous locking of multiple laser output phases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

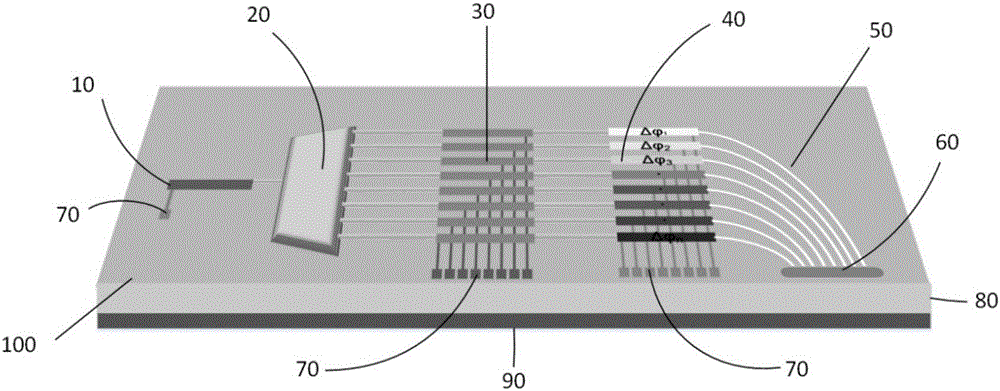

[0050] The active optical phased array photonic integrated chip 100 with an operating wavelength range of 1.3 μm˜2.0 μm may be based on the same InP substrate 80 . The substrate 80 is either highly doped n-InP, and the back electrode 90 is located on the back of the substrate 80 ; or is semi-insulating InP, and the back electrode 90 is located on the front of the substrate 80 .

[0051] The semiconductor epitaxial structure, waveguide structure and wavelength selection structure of the master laser 10 and the slave laser array 30 are the same. The semiconductor epitaxial structure adopts p-i-n structure, the p and n layers can use InP or AlInAs, the thickness range is 1-2μm, and the i layer can use InGaAs, InGaAsP, AlGaInAs and other ternary or quaternary alloy III-V compound semiconductor multiple quantum wells structure, the corresponding emission spectrum peak ranges from 1.2 μm to 2.0 μm, and the thickness ranges from 0.05 to 0.5 μm.

[0052] Laser wavelength or frequency...

Embodiment 2

[0059] The active optical phased array photonic integrated chip 100 with an operating wavelength range of 0.6 μm˜1.1 μm may be based on the same GaAs or GaP substrate 80 . The substrate 80 is either a highly doped substrate, and the back electrode 90 is located on the back of the substrate 80 ; or is a semi-insulating substrate, and the back electrode 90 is located on the front of the substrate 80 .

[0060] The semiconductor epitaxial structure, waveguide structure, and wavelength selection structure of the master laser 10 and the slave laser array 30 are the same, the semiconductor epitaxial structure adopts a p-i-n structure, the p and n regions can use GaAlAs or GaInP, and the thickness range is 0.2-2 μm, and the i region can use GaAlAs , AlGaInP and other ternary or quaternary alloy III-V compound semiconductors, the corresponding emission spectrum peak range is 0.6 μm to 1.1 μm, and the thickness range is 0.05 to 0.5 μm.

[0061] Laser wavelength or frequency selection i...

specific Embodiment approach

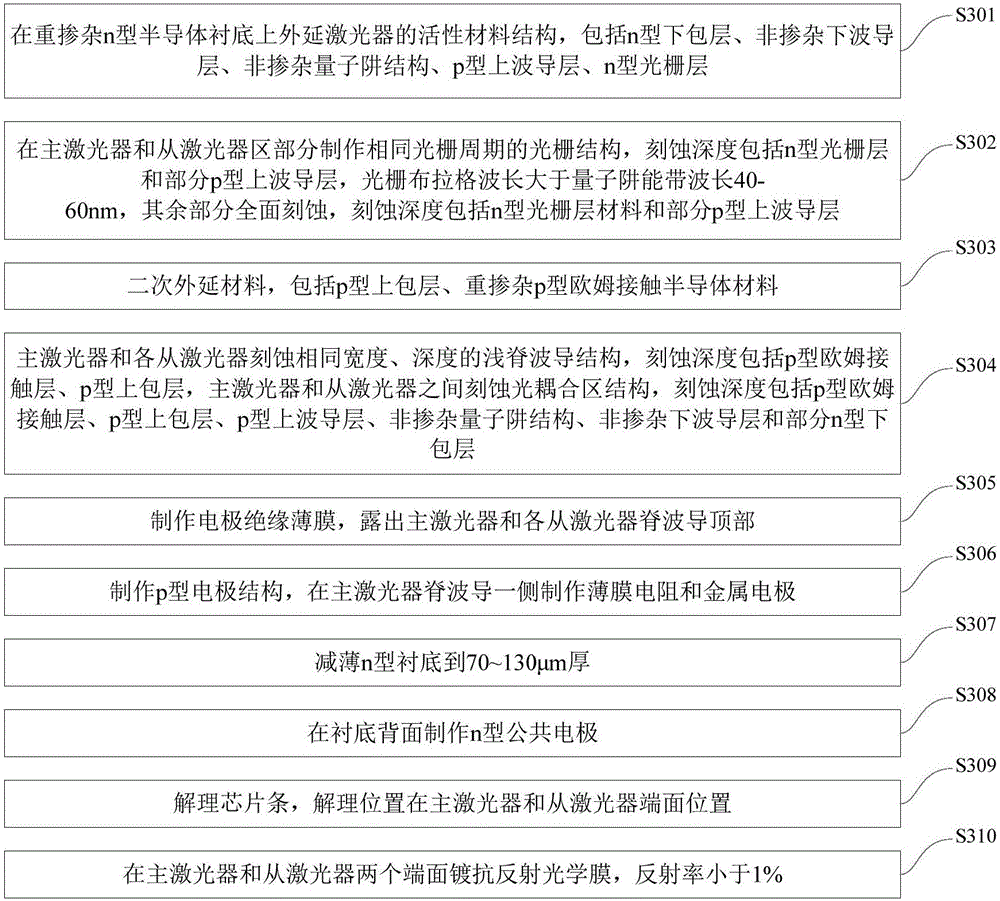

[0083] In a specific embodiment of the present invention, a method for preparing an active optical phased array photonic integrated chip with a wavelength of about 1550 nm is taken as an example. The active optical phased array photonic integrated chip includes a master laser, an optical isolation coupling region, a slave laser array, an optical phase modulator array, a transition waveguide array, an optical field radiation array, a positive electrode, a substrate and a back electrode. All devices use the same epitaxial structure. The specific implementation is as follows:

[0084] On a highly doped n-type InP substrate, the following materials are grown by metal organic chemical vapor phase epitaxy (MOVPE): n-type InP buffer layer (thickness 1000nm, doping concentration about 1×10 18 cm -3 ), i-layer 400nm, including undoped lattice matching InGaAsP lower waveguide layer (thickness 100nm, optical fluorescence wavelength 1150nm), InGaAsP active layer multiple quantum wells (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com