Transparent film varactor and preparation method thereof

A transparent film and varactor technology, which is applied in the manufacture of capacitors, variable voltage capacitors, capacitors, etc., can solve the problems of reducing the dielectric tuning rate, large dielectric loss, and small dielectric constant, so as to improve the dielectric constant. Tuning rate, reduction of dielectric loss, and large effect of dielectric tuning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

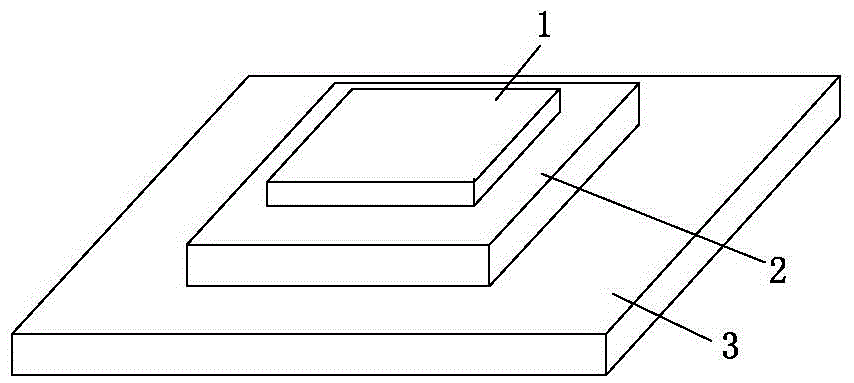

[0036] A kind of transparent film varactor of the present embodiment, see figure 1 As shown, it includes a substrate 3 , a barium tin titanate thin film 2 deposited on the substrate 3 , and an electrode 1 connected to the barium tin titanate thin film 2 .

[0037] In this embodiment, the chemical formula of barium tin titanate in the barium tin titanate film 2 is BaSn 0.15 Ti 0.85 o 3 .

[0038] In this embodiment, the thickness of the barium tin titanate thin film 2 is 350 nm.

[0039] In this embodiment, the substrate 3 is an FTO glass substrate.

[0040] In this embodiment, the electrode 1 is a cylindrical electrode, and the diameter of the cylindrical electrode is 0.2 mm. Wherein, the cylindrical electrode in this embodiment is a cylindrical gold electrode.

[0041] A kind of preparation method of transparent film varactor of the present embodiment, it comprises the following steps:

[0042] Step 1, preparation of barium tin titanate target material: The raw materia...

Embodiment 2

[0047] A kind of transparent film varactor of the present embodiment, see figure 1 As shown, it includes a substrate 3 , a barium tin titanate thin film 2 deposited on the substrate 3 , and an electrode 1 connected to the barium tin titanate thin film 2 .

[0048] In this embodiment, the chemical formula of barium tin titanate in the barium tin titanate film 2 is BaSn 0.15 Ti 0.85 o 3 .

[0049] In this embodiment, the thickness of the barium tin titanate thin film 2 is 100 nm.

[0050] In this embodiment, the substrate 3 is an FTO glass substrate.

[0051] In this embodiment, the electrode 1 is a cylindrical electrode, and the diameter of the cylindrical electrode is 0.05 mm. Wherein, the cylindrical electrode in this embodiment is a cylindrical gold electrode.

[0052] A kind of preparation method of transparent film varactor of the present embodiment, it comprises the following steps:

[0053] Step 1, preparation of barium tin titanate target material: The raw materi...

Embodiment 3

[0058] A kind of transparent film varactor of the present embodiment, see figure 1 As shown, it includes a substrate 3 , a barium tin titanate thin film 2 deposited on the substrate 3 , and an electrode 1 connected to the barium tin titanate thin film 2 .

[0059] In this embodiment, the chemical formula of barium tin titanate in the barium tin titanate film 2 is BaSn 0.15 Ti 0.85 o 3 .

[0060] In this embodiment, the thickness of the barium tin titanate thin film 2 is 600 nm.

[0061] In this embodiment, the substrate 3 is an FTO glass substrate.

[0062] In this embodiment, the electrode 1 is a cylindrical electrode, and the diameter of the cylindrical electrode is 0.3 mm. Wherein, the cylindrical electrode in this embodiment is a cylindrical gold electrode.

[0063] A kind of preparation method of transparent film varactor of the present embodiment, it comprises the following steps:

[0064] Step 1, preparation of barium tin titanate target material: the raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com