Galactosyl grafted-modified alginate microspheres and applications thereof

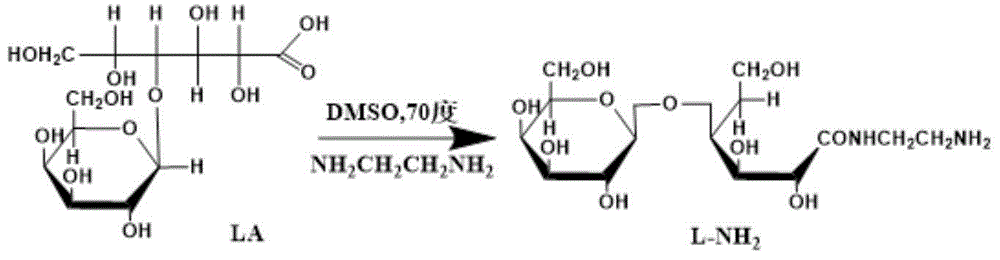

A technology of galactose and alginate, which is applied in the direction of fixing on/in the organic carrier, can solve problems such as the inability to introduce galactose groups, and achieve the maintenance of immune isolation performance, excellent biocompatibility, and conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Preparation of alginic acid solution: Alginic acid was dissolved in water to prepare a 1 g / L alginic acid solution with a volume of 500 mL. Among them, the molecular weight of alginic acid is 350kDa.

[0045] 2) Filter the solution of 1) to remove impurities, and adjust the pH of the alginic acid solution to 10 with a mass concentration of 240g / L NaOH solution.

[0046] 3) Dissolve 0.06g of CNBr solid with 0.5mL of acetonitrile and add it dropwise into the alginic acid solution in step 2), and keep the pH value constant.

[0047] 4) Cleaning the activated solution prepared in step 3) until the unreacted CNBr small molecule is removed.

[0048] 5) Add 0.4 g of lactosamine solid to the washed solution, and stir at room temperature for 2 days.

[0049] 6) Washing the solution after the reaction in step 5) until unreacted lactosamine molecules are removed.

[0050] 7) Freeze-drying the washed solution in step 6) to obtain galactosyl alginic acid with a grafting degree...

Embodiment 2

[0079] 1) Preparation of sodium galactosyl alginate solution: galactosyl alginic acid was dissolved in physiological saline to prepare a 15 g / L sodium galactosyl alginate solution, wherein the molecular weight of galactosyl alginate was 350 kDa.

[0080] 2) Preparation of chitosan solution: chitosan was dissolved in acetic acid-sodium acetate buffer solution with a pH of 6.0, and the concentration of chitosan was 5 g / L. Among them, the molecular weight of chitosan is 30kDa, and the degree of deacetylation is 90%.

[0081] 3) Preparation of gel bath solution: Anhydrous calcium chloride was dissolved in deionized water to prepare a 11 g / L calcium chloride solution.

[0082]4) Preparation of galactosyl calcium alginate / chitosan microcapsules: prepare galactosyl calcium alginate embedded hydrogel microspheres by high-voltage electrostatic method, and immerse the embedded hydrogel microspheres in chitosan solution In this method, the volume ratio of embedded hydrogel microspheres ...

Embodiment 3

[0085] 1) Preparation of galactosyl sodium alginate solution: galactosyl alginic acid was dissolved in physiological saline to prepare a 15 g / L galactosyl sodium alginate solution, which was sterile filtered. Among them, the molecular weight of galactosyl alginic acid is 350kDa.

[0086] 2) Preparation of α-polylysine solution: α-polylysine was dissolved in physiological saline to prepare a 5 g / L α-polylysine solution, which was sterile filtered. Among them, the molecular weight of α-polylysine is 30kDa.

[0087] 3) Preparation of gel bath solution: Anhydrous calcium chloride was dissolved in deionized water to prepare a 11 g / L calcium chloride solution, which was sterilized by filtration.

[0088] 4) Prepare galactosyl calcium alginate / α-polylysine-embedded hydrogel microsphere carrier that wraps liver cells: take 3mL galactosyl sodium alginate solution, add 6*10 ^6 Rat primary hepatocytes were mixed evenly, and galactosyl calcium alginate-embedded hydrogel microspheres emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com