Adhesive tape for processing process protection

A tape and process technology, applied in the field of process protection tapes, can solve the problems such as the inability to apply the corners and radians well, the incomplete wrapping of the protective film, affecting the appearance and yield of the product, etc., to reduce the risk of edge warping , Perfect rework effect, good sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

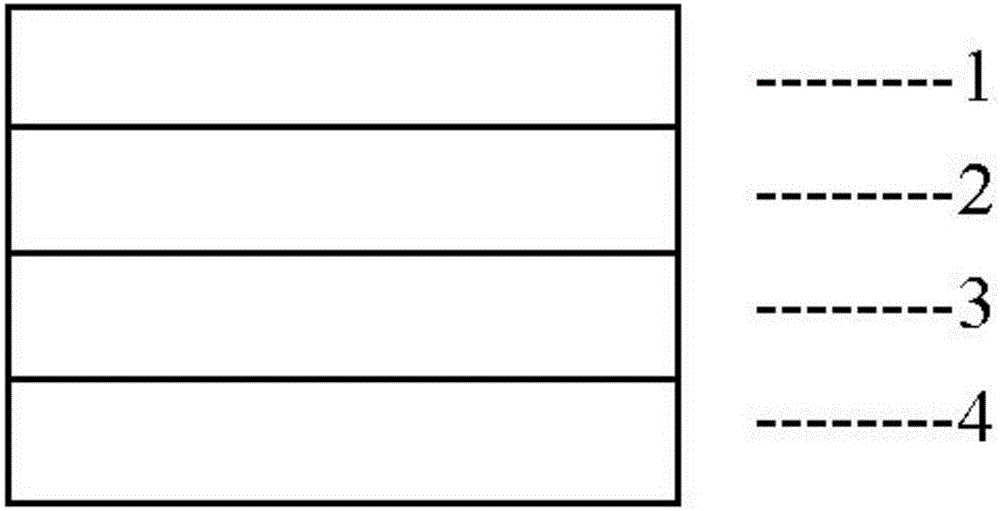

[0028] An adhesive tape for process protection, characterized in that it includes a release film layer 1, a heat-sensitive adhesive layer 2, a pressure-sensitive adhesive layer 3 and a substrate layer 4 that are laminated in sequence, such as figure 1 shown. Wherein, the substrate layer 4 is a polyethylene film, the release film layer 1 is a silicon-based release film, and the heat-sensitive adhesive layer 2 is a rubber heat-sensitive adhesive. The thickness of the base material layer 4 was 30 μm.

[0029] The above-mentioned rubber heat-sensitive adhesive is made of the following components by weight: 45 parts of styrene-butadiene-styrene block copolymer, 55 parts of terpene resin, 1 part of alkane paraffin, 2,6-di 5 parts of tert-butyl p-cresol (antioxidant 264).

[0030] The preparation method of above-mentioned adhesive tape is as follows:

[0031] 1) Preparation of rubber heat-sensitive adhesive: respectively dissolving styrene-butadiene-styrene block copolymer and ter...

Embodiment 2

[0036] An adhesive tape for process protection, characterized in that it includes a release film layer 1, a heat-sensitive adhesive layer 2, a pressure-sensitive adhesive layer 3 and a substrate layer 4 that are laminated in sequence, such as figure 1 shown. Wherein, the substrate layer 4 is a polyvinyl chloride film, the release film layer 1 is a silicon-based release film, and the heat-sensitive adhesive layer 2 is a rubber heat-sensitive adhesive. The thickness of the substrate layer was 50 μm.

[0037] The above-mentioned rubber heat-sensitive adhesive is made of the following components in parts by weight: 50 parts of styrene-isoprene-styrene block copolymer, 60 parts of rosin resin, 5 parts of alkane paraffin, phthalate di 5 parts of octyl ester (DOP), 10 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010).

[0038] The preparation method of above-mentioned process protection adhesive tape is as follows:

[0039...

Embodiment 3

[0044] An adhesive tape for process protection, characterized in that it includes a release film layer 1, a heat-sensitive adhesive layer 2, a pressure-sensitive adhesive layer 3 and a substrate layer 4 that are laminated in sequence, such as figure 1 shown. Wherein, the substrate layer 4 is a polyethylene film, the release film layer 1 is a silicon-based release film, and the heat-sensitive adhesive layer 2 is a rubber heat-sensitive adhesive. The thickness of the substrate layer was 100 μm.

[0045] The above-mentioned rubber heat-sensitive adhesive is made of the following components by weight: 40 parts of styrene-ethylene-butylene-styrene block copolymer, 50 parts of petroleum resin, 2 parts of microcrystalline paraffin, 2,2' - 2 parts of methylenebis(4-methyl-6-tert-butylphenol) (antioxidant 2246).

[0046] The preparation method of above-mentioned process protection adhesive tape is as follows:

[0047] 1) Preparation of rubber heat-sensitive adhesive: respectively di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com