A kind of preparation method of efficient photocatalyst srtio3

A photocatalyst and high-efficiency technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high cost, difficult recovery, and high reaction temperature. Low equipment requirements, simple process steps, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Efficient photocatalyst SrTiO 3 A preparation method comprising the steps of:

[0023] 1), put 3.2121g of strontium acetylacetonate, 3.2544g (3.39ml) of isopropyl titanate, 400ml of dibenzyl ether, 80ml of oleylamine and 80ml of oleic acid into a three-necked round-bottomed flask, in a protective atmosphere (99.9% high-purity nitrogen, the same below), magnetically stirred at 35° C. to dissolve completely.

[0024] 2) Under a protective atmosphere, the temperature was raised to 120°C, and then stirred at constant temperature for 1.5 hours.

[0025] 3) Under a protective atmosphere, the temperature was raised to 140° C., and then stirred at a constant temperature for 6 hours to prepare a strontium titanate precursor.

[0026] 4) Wash the strontium titanate precursor with absolute ethanol, then centrifuge and dry to obtain a powder. The drying temperature is 120° C. and the drying time is 4 hours.

[0027] 5) Calcining the powder in a muffle furnace at 400°C for 2 hour...

Embodiment 2~5

[0029] The only difference from Example 1 is that the calcination temperatures are 500°C, 600°C, 700°C, and 800°C in sequence.

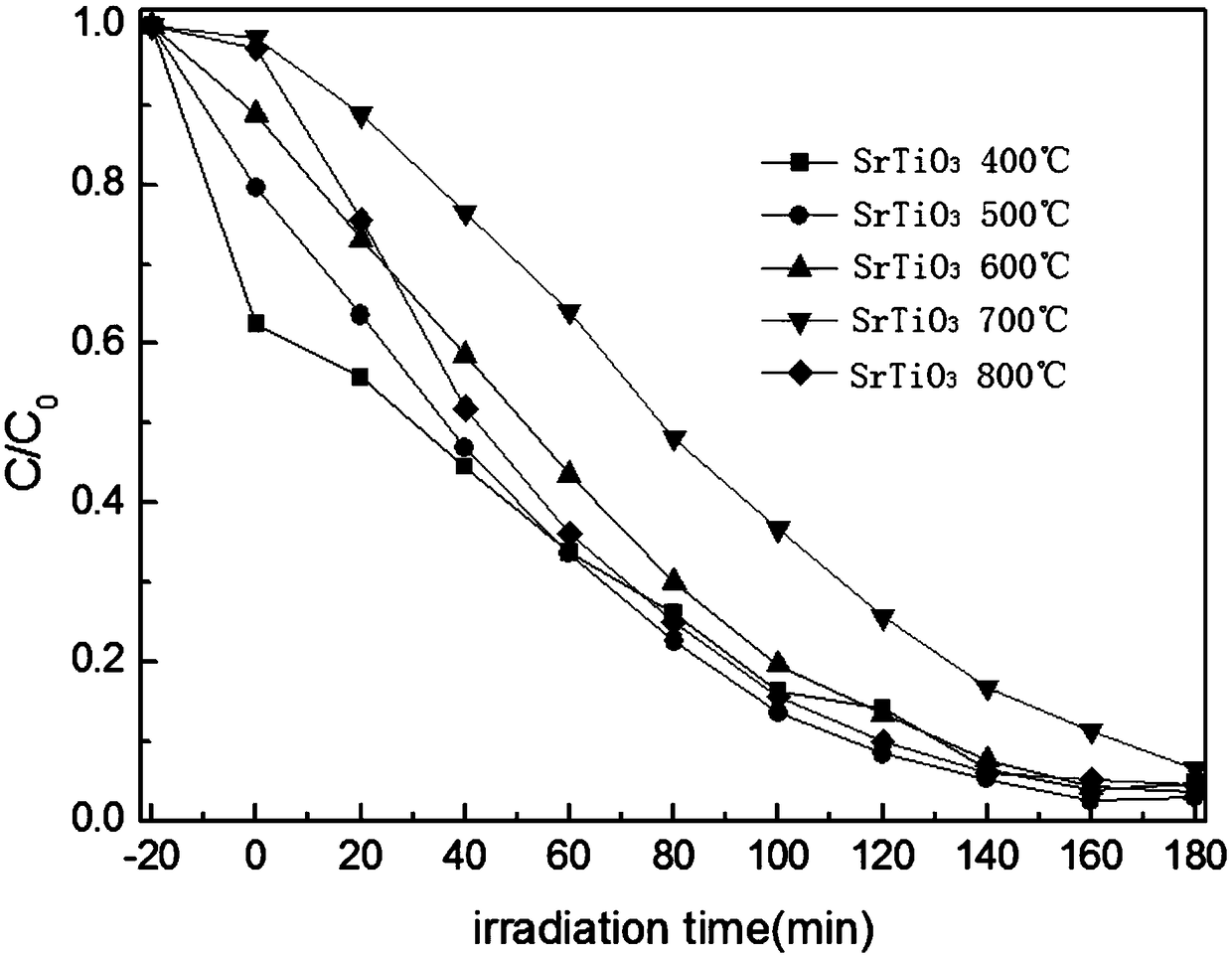

[0030] Product performance characterization:

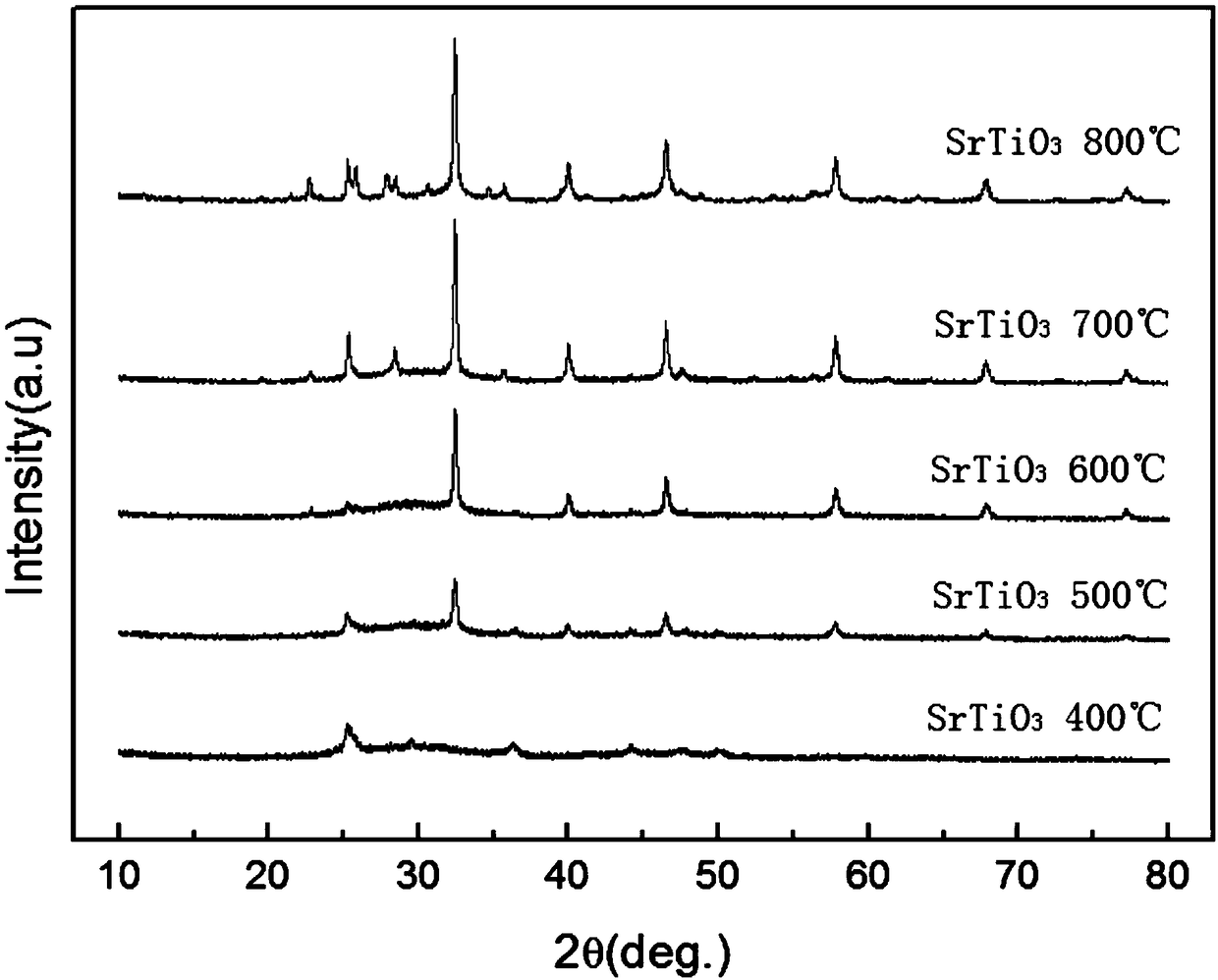

[0031] 1. X-ray diffraction test

[0032] Utilize X-ray powder diffractometer (XRD) to test respectively the strontium titanate photocatalyst material that embodiment 1~5 prepares, by figure 1 Compared with the standard PDF card (No.35-0734) in the position and relative intensity of each diffraction peak, the prepared sample is a strontium titanate photocatalytic material, and there is a trace amount of titanium dioxide; The improvement of catalytic performance has a great promotion effect, and each peak in the spectrum is sharp, indicating that the crystallization degree of the sample is good.

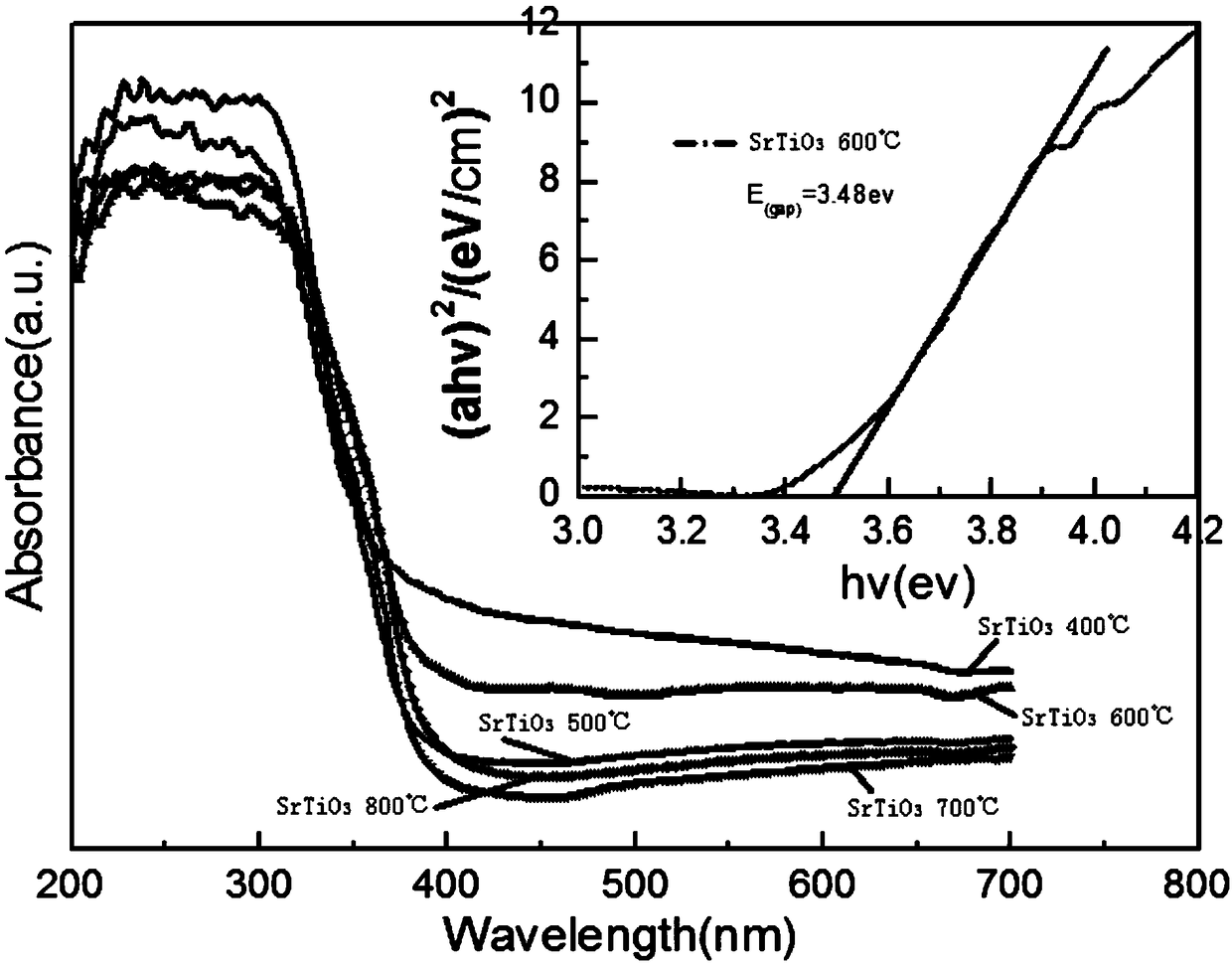

[0033] 2. UV test

[0034] The strontium titanate photocatalytic materials prepared in Examples 1 to 5 were respectively tested with an ultraviolet spectrophotometer (UV; UV-3600), and the forbidden band widt...

Embodiment 6

[0039] Efficient Photocatalyst SrTiO 3 A preparation method comprising the steps of:

[0040] 1), the oleic acid of the strontium acetylacetonate of 3.3526g, the isopropyl titanate of 3.1525g, the dibenzyl ether of 450ml, the oleylamine of 100ml and the oleic acid of 60ml are put in the three-necked round bottom flask, under protective atmosphere (99.9% high Pure nitrogen, the same below), magnetically stirred at 30°C to dissolve completely.

[0041] 2) Under a protective atmosphere, the temperature was raised to 100° C., and then stirred at constant temperature for 2 hours.

[0042] 3) Under a protective atmosphere, the temperature was raised to 120° C., and then stirred at a constant temperature for 8 hours to prepare a strontium titanate precursor.

[0043] 4) Wash the strontium titanate precursor with absolute ethanol, then centrifuge and dry to obtain a powder. The drying temperature is 90° C. and the drying time is 5 hours.

[0044] 5) Calcining the powder in a muffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com