Nanophase/metal composite powder and powder metallurgy preparation method of bulk material

A metal composite and metal powder technology, applied in the field of metal matrix composite material preparation, can solve the problems of inability to simultaneously satisfy nano-phase dispersibility, poor dispersion effect of carbon nanotubes, lack of deformability of flake powder, etc., and achieve excellent effects, Less metallurgical defects and good structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

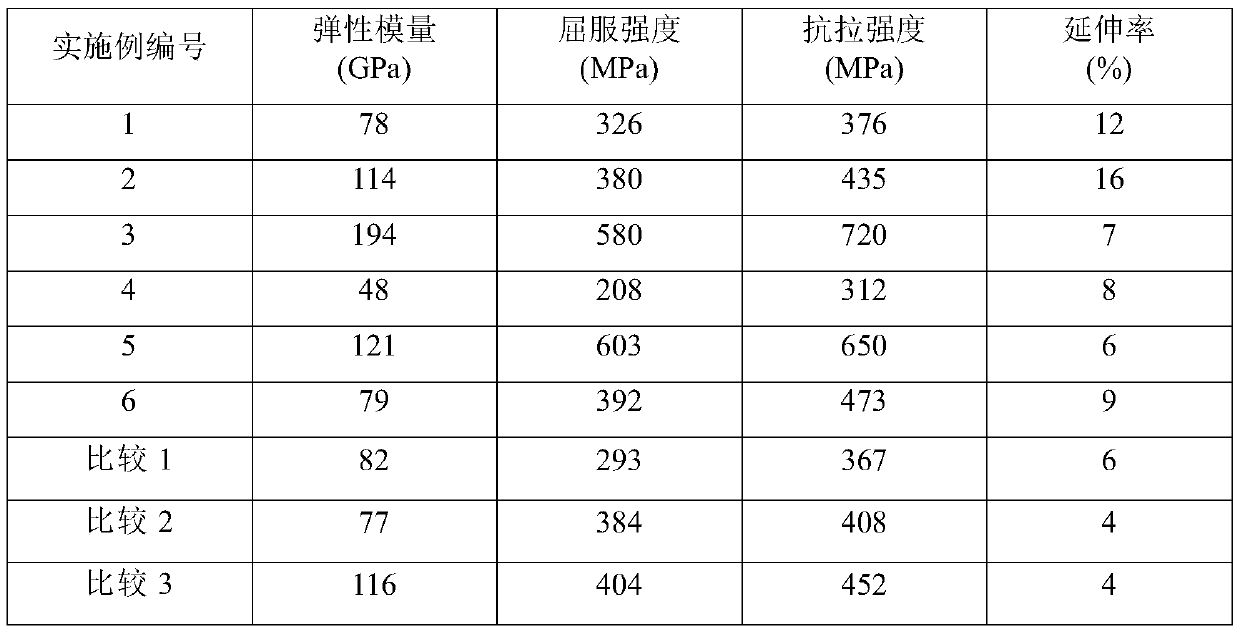

Examples

preparation example Construction

[0028] The preparation method of nanophase / metal composite powder of the present invention comprises the following steps:

[0029] (1) Add the nanophase powder and metal powder to the ball mill tank after weighing according to the design ratio;

[0030] (2) The mixed powder is subjected to low-speed ball milling for a long time to obtain uniformly dispersed sheet-like composite powder;

[0031] (3) The flake composite powder is subjected to short-time high-speed ball milling to obtain nanophase / metal granular composite powder;

[0032]On the basis of the above-mentioned nanophase / metal granular composite powder, the densification of the nanophase / metal granular composite powder is achieved through powder metallurgy techniques such as pressing, sintering and plastic deformation, and the nanophase / metal composite bulk material is obtained.

Embodiment 1

[0034] Carbon Nanotube / Aluminum Composite

[0035] Spherical aluminum powder with a purity greater than 99.5% and an average particle diameter of 10 microns is used as the metal matrix powder, and multi-walled carbon nanotubes with an outer diameter of 20-40 nanometers and a length of 2-5 microns are used as the nanophase powder.

[0036] The carbon nanotube / aluminum mixed powder is placed in a planetary ball mill, the mass fraction of carbon nanotubes is 2%, the ball-to-material ratio is 20:1, ball milling at a low speed of 135 rpm for 8 hours, and ball milling at a high speed of 270 rpm for 1 hour to prepare carbon nanotubes / aluminum Aluminum granular composite powder.

[0037] The carbon nanotube / aluminum granular composite powder was hot-pressed and sintered at 300 MPa and 550 °C for 2 h in a vacuum environment, and then extruded into a round rod sample at 420 °C at a rate of 1 mm / min and an extrusion ratio of 25:1.

Embodiment 2

[0039] Graphene / copper composites

[0040] The spherical copper powder prepared by the atomization method has a purity greater than 99.5% and an average particle size of 30 microns; the graphene nanosheets prepared by the oxidation-reduction method have a thickness of 1-3 nanometers and a diameter of 0.5-2 microns.

[0041] Put the graphene / copper mixed powder in the stirring ball mill, the mass fraction of graphene is 0.5%, add the stearic acid with mass fraction of 1%, the ratio of ball to material is 15:1, take it out after ball milling at a low speed of 150rpm for 6h, put In a planetary ball mill, ball mill at a high speed of 426rpm for 0.5h to prepare graphene / copper granular composite powder.

[0042] After the graphene / copper granular composite powder is cold-pressed at 500MPa, it is sintered at 950°C for 4 hours under an argon atmosphere, and then upset at 700°C to a 25% downsetting amount to obtain a graphene / copper composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com