A high-efficiency processing method for aeroengine swirlers

A technology of aero-engine and process method is applied in the field of high-efficiency processing of aero-engine swirler, which can solve the problems affecting the normal operation of aero-engine for a long time, unstable surface quality of blade swirler, metallurgical defects of blade swirler, etc. Excellent mechanical properties, improved metal stability, less metallurgical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

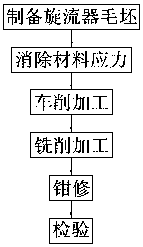

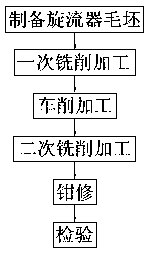

[0037] Such as figure 1 , Figure 4 As shown, a process method for efficiently processing the swirler of an aero-engine includes the step of preparing a swirler blank, the swirler blank is made of a columnar forging, and the forging includes a forging and a forged bar , the columnar forging is made of aviation materials, and also includes a step of preparing a semi-finished product of the cyclone and a trimming step, and the step of preparing the semi-finished product of the cyclone is to subject the blank of the cyclone to at least one turning process and at least one milling process , to obtain a cyclone semi-finished product, the clamping step is to trim the outer profile of the cyclone semi-finished product according to the requirements of the aero-engine cyclone finished product, so as to obtain the cyclone finished product.

[0038] In this embodiment, a high-efficiency processing method for aero-engine swirlers uses columnar forgings as raw materials. Since the metal s...

Embodiment 2

[0047] Such as figure 1 , Figure 4 As shown, a high-efficiency processing method of the aero-engine swirler of this embodiment is the same as the process of embodiment 1, the difference is that the inspection step is a test of installing the finished swirler on the test aero-engine detection.

[0048] A kind of high-efficiency processing method of aero-engine swirler in this embodiment adopts the method of directly installing the finished swirler finished product on the test aero-engine for actual detection, on the one hand, it is beneficial to measure the mass-produced swirler Information parameters such as strength, toughness, and durable life of the finished product. On the other hand, the processing technology of the finished cyclone can also be improved according to the measured information parameters, so that the improved parameters obtained can be applied to other parts in the aviation field. In the development and processing of the aviation field, the processing of ...

Embodiment 3

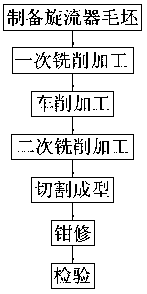

[0050] Such asfigure 1 , Figure 4 As shown, a kind of high-efficiency processing method of the aero-engine swirler of this embodiment is the same as the process of embodiment 1, the difference is that the clamp repair step includes the step of grinding the swirl groove, and the grinding swirl groove The step is to grind and trim the root of the swirler blade, and form an arc-shaped surface for controlling the direction of the airflow at the root of the swirler blade.

[0051] A kind of high-efficiency processing method of the aero-engine swirler of this embodiment, grinding and trimming the root of the swirler blade, forming an arc-shaped surface for controlling the airflow direction at the root of the swirler blade, increasing the strength of the swirler blade root , improve the service life of the finished cyclone, and at the same time, when the finished cyclone rotates during use, the airflow flows along the arc surface and rotates with the cyclone to form a spiral conveye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com