A kind of perovskite solar cell and preparation method thereof

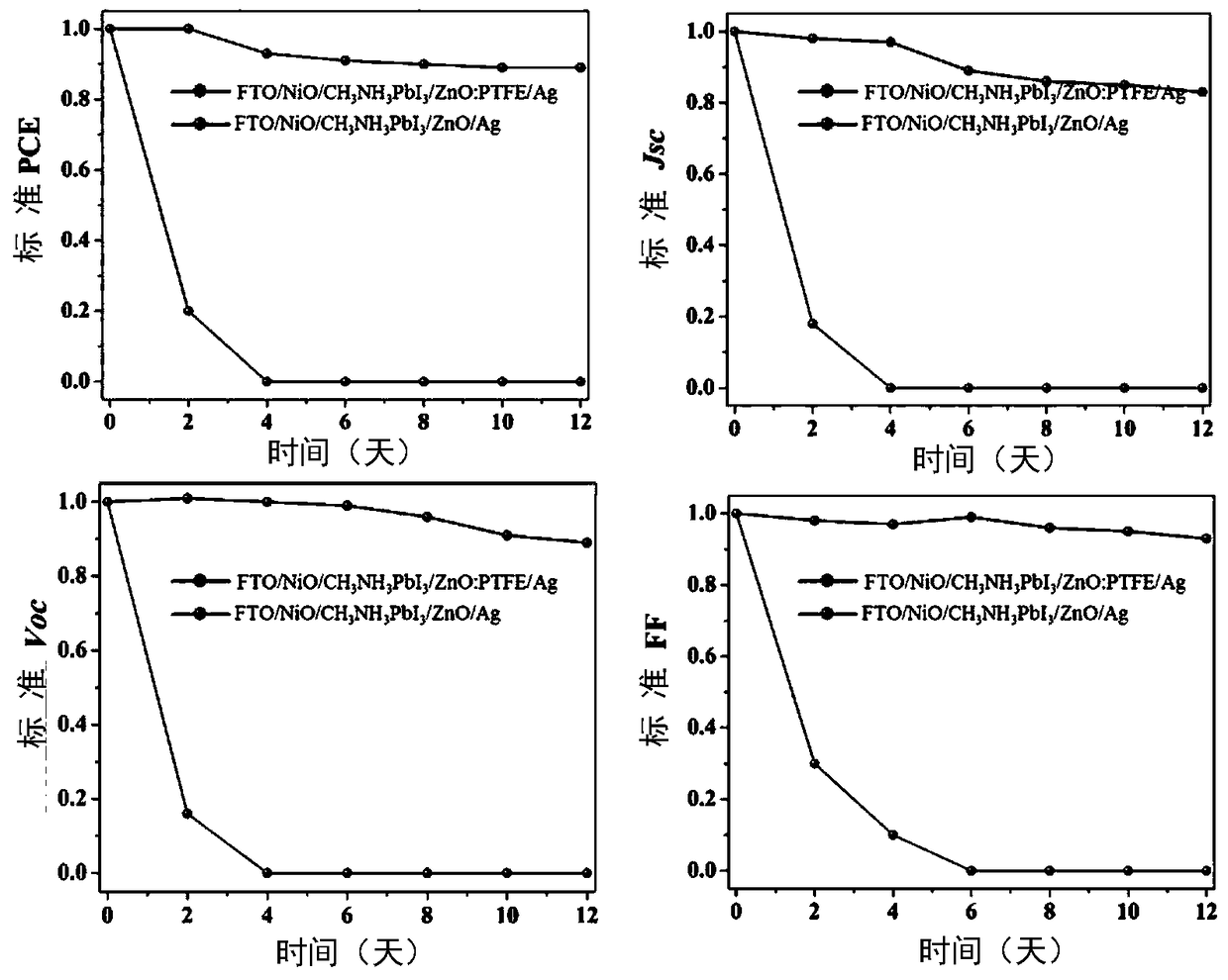

A solar cell and perovskite technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of improving the stability of perovskite solar cell performance, such as limitations, and achieve long-term stability and low specific surface energy , the effect of inhibiting penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] First prepare the polytetrafluoroethylene network. The raw material is pure polytetrafluoroethylene powder, and the air pressure in the evaporation chamber is pumped to 5×10 -4 Pa, control the evaporation current 30A, the distance between the substrate and the powder is 12cm, the initial substrate temperature is room temperature, and the substrate does not need to be heated during the entire evaporation process, and the deposition time is 15 minutes;

[0061] Then the sample is transferred to the sputtering chamber, which is filled with 1:6 high-purity argon and oxygen, the total pressure is controlled at 1.5Pa, the distance between the target and the substrate is controlled at 8cm, and the initial substrate temperature is room temperature, and no additional heating is required throughout the process. Turn on the DC power supply, control the power of the DC power supply to 100W, sputter the pure zinc target material, and the deposition time is 15 minutes. Finally, the...

Embodiment 2

[0063] First prepare the polytetrafluoroethylene network. The raw material is pure polytetrafluoroethylene powder, and the air pressure in the evaporation chamber is pumped to 5×10 -4 Pa, control the evaporation current 30A, the distance between the substrate and the powder is 12cm, the initial substrate temperature is room temperature, and the substrate does not need to be heated during the entire evaporation process, and the deposition time is 15 minutes;

[0064] Then the sample is transferred to the sputtering chamber, which is filled with 1:6 high-purity argon and oxygen, the total pressure is controlled at 1.5Pa, the distance between the target and the substrate is controlled at 8cm, and the initial substrate temperature is room temperature, and no additional heating is required throughout the process. Turn on the DC power supply, control the power of the DC power supply to 200W, sputter the pure zinc target material, and the deposition time is 15 minutes. Finally, ref...

Embodiment 3

[0066] First prepare the polytetrafluoroethylene network. The raw material is pure polytetrafluoroethylene powder, and the air pressure in the evaporation chamber is pumped to 5×10 -4 Pa, control the evaporation current 30A, the distance between the substrate and the powder is 12cm, the initial substrate temperature is room temperature, and the substrate does not need to be heated during the entire evaporation process, and the deposition time is 15 minutes;

[0067] Then the sample is transferred to the sputtering chamber, which is filled with 1:6 high-purity argon and oxygen, the total pressure is controlled at 1.5Pa, the distance between the target and the substrate is controlled at 8cm, and the initial substrate temperature is room temperature, and no additional heating is required throughout the process. Turn on the DC power supply, control the power of the DC power supply to 300W, sputter the pure zinc target material, and the deposition time is 15 minutes. Finally, ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com