Anti-peeling polypropylene metallized film preparing process

A technology of polypropylene film and metallized film, which is applied in the field of capacitors, can solve the problems of weak adhesion between polypropylene film and metal coating, affect the service life of capacitors, and the metal coating is easy to be broken down, so as to improve the bonding strength and improve the use The effect of reducing the chance of life and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

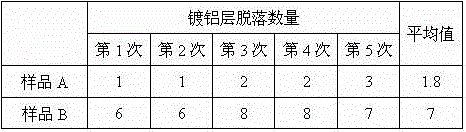

Embodiment 1

[0015] After the corona discharge treatment is carried out on the working surface of the polypropylene film, the process condition of the corona discharge treatment is 30~35J / cm 2 . Then the polypropylene film is subjected to heat-drawing process sequentially. The heat-drawing process is as follows: the polypropylene film is sent into the treatment tank, and the amyl alcohol solution of the titanate coupling agent is continuously introduced into the treatment tank, and the titanate coupling agent is The mass fraction of the amyl alcohol solution is 12.5%~13.5%, the temperature of the amyl alcohol solution of the titanate coupling agent is 125~135°C, and the polypropylene film is stretched at a rate of 20~22mm / min by 109%~112 %; and then dry the polypropylene film with hot air at 90~95°C. The polypropylene film is subjected to the cold drawing process after the hot drawing process. The cold drawing process is: the polypropylene film is stretched by 100.6%~101.3% at a rate of 0...

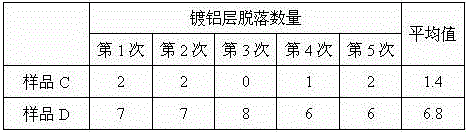

Embodiment 2

[0022] After the corona discharge treatment is carried out on the working surface of the polypropylene film, the process condition of the corona discharge treatment is 33J / cm 2 . Then the polypropylene film is subjected to heat-drawing process sequentially. The heat-drawing process is as follows: the polypropylene film is sent into the treatment tank, and the amyl alcohol solution of the titanate coupling agent is continuously introduced into the treatment tank, and the titanate coupling agent is The mass fraction of the amyl alcohol solution is 13.1%, the temperature of the amyl alcohol solution of the titanate coupling agent is 129°C, and the polypropylene film is stretched by 111% at a rate of 21mm / min; The polypropylene film was blown dry. The polypropylene film is subjected to a cold drawing process after being processed by a hot drawing process. The cold drawing process is as follows: the polypropylene film is stretched by 100.9% at a rate of 0.5mm / min at room temperatu...

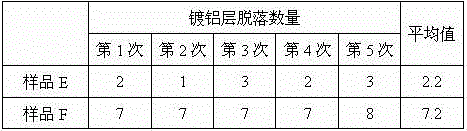

Embodiment 3

[0029] After the corona discharge treatment is carried out on the working surface of the polypropylene film, the process condition of the corona discharge treatment is 35J / cm 2 . Then the polypropylene film is subjected to heat-drawing process sequentially. The heat-drawing process is as follows: the polypropylene film is sent into the treatment tank, and the amyl alcohol solution of the titanate coupling agent is continuously introduced into the treatment tank, and the titanate coupling agent is The mass fraction of the pentanol solution is 13.5%, the temperature of the pentanol solution of the titanate coupling agent is 135°C, and the polypropylene film is stretched by 112% at a rate of 22mm / min; The polypropylene film was blown dry. The polypropylene film is subjected to a cold drawing process after being processed by a hot drawing process. The cold drawing process is as follows: the polypropylene film is stretched by 101.3% at a rate of 0.8mm / min at room temperature.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com