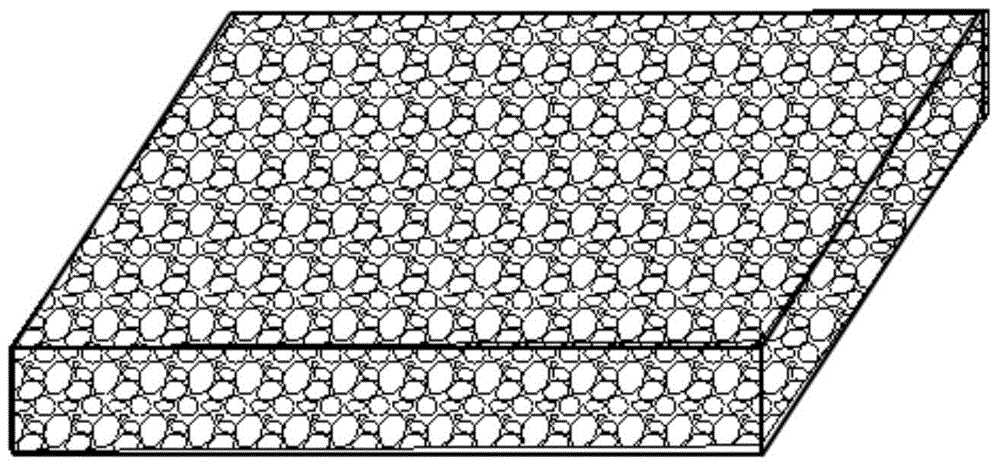

A kind of inorganic foam building insulation board and preparation method thereof

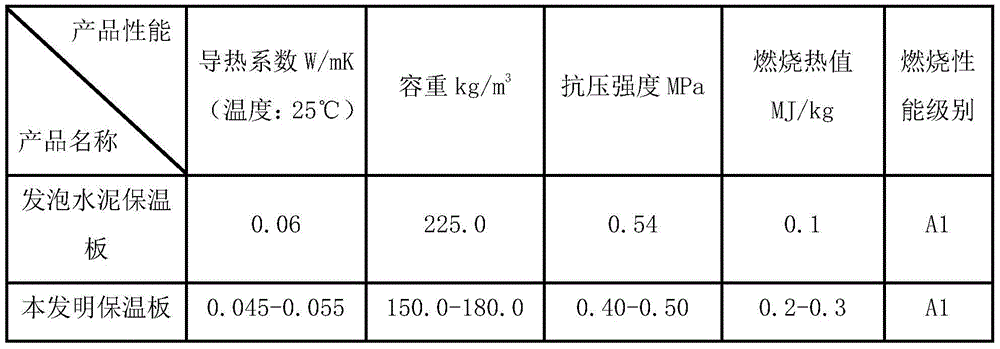

A technology of building heat preservation and inorganic foaming, applied in heat preservation, construction, building components, etc., can solve problems such as black smoke, easy penetration, irritating odor, etc., and achieve extended service life, good heat preservation performance, super strong The effect of stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

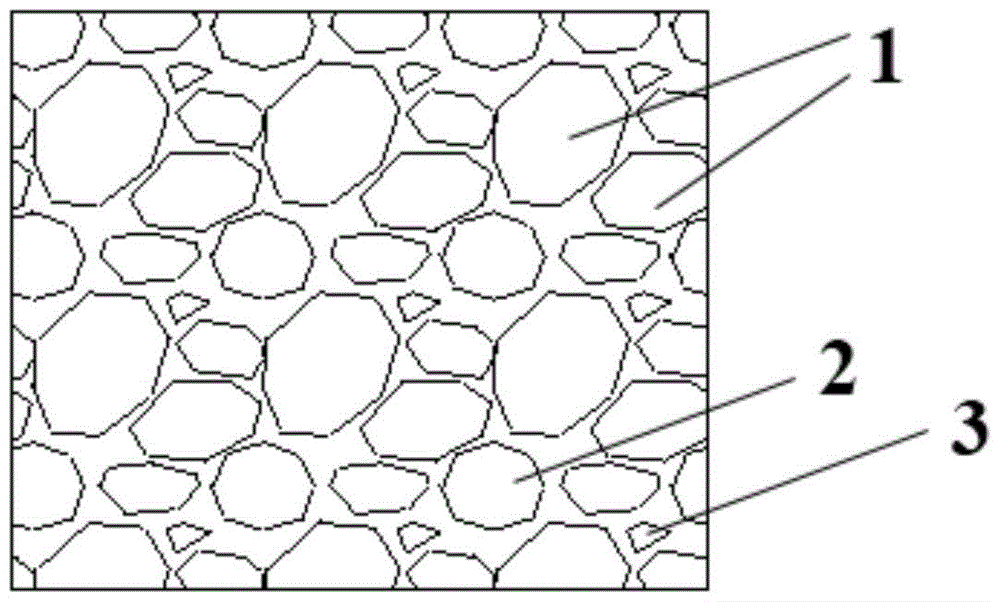

Method used

Image

Examples

Embodiment 1

[0046] (1) 25g of modified expanded perlite A, 45g of silica airgel, 100g of hollow vitrified microspheres, 10g of halloysite nanotubes, 100g of mixed flame retardant A, and 250g of mixed gelling material A are sent into the mixer Stir evenly, and the stirring time is 0.5 hours.

[0047] (2) Add 300 g of water and stir for 10 minutes in the powder material stirred uniformly in step (1), then add 10 g of ammonium bicarbonate in the mixed slurry and stir for 10 minutes.

[0048] (3) Pour the mixed slurry uniformly stirred in step (2) into the mold, wait for it to foam and form, and then dry it naturally to obtain an inorganic foamed building insulation board. The prepared inorganic foamed building insulation board The length is 300mm; the width is 300mm, and the height is 40mm.

Embodiment 2

[0050] (1) 35g of modified expanded perlite B, 50g of silica airgel, 130g of hollow vitrified microspheres, 15g of halloysite nanotubes, 120g of mixed flame retardant B, and 300g of mixed gelling material B are sent into the mixer Stir evenly, and the stirring time is 1 hour.

[0051] (2) Add 400g of water to the powder stirred uniformly in step (1) and stir for 20 minutes, then add 15g of ammonium bicarbonate to the mixed slurry and stir for 15 minutes.

[0052] (3) Pour the mixed slurry uniformly stirred in step (2) into the mold, wait for it to foam and form, and then dry it naturally to obtain an inorganic foamed building insulation board. The prepared inorganic foamed building insulation board The length is 600mm; the width is 600mm, and the height is 60mm.

Embodiment 3

[0054] (1) 30g of modified expanded perlite C, 48g of silica airgel, 110g of hollow vitrified microspheres, 12g of halloysite nanotubes, 110g of mixed flame retardant C, and 270g of mixed gelling material C are sent into the mixer Stir evenly, and the stirring time is 0.8 hours.

[0055] (2) Add 360g of water to the powder stirred uniformly in step (1) and stir for 15 minutes, then add 10g of sodium bicarbonate to the mixed slurry and stir for 12 minutes.

[0056] (3) Pour the mixed slurry uniformly stirred in step (2) into the mold, wait for it to foam and form, and then dry it naturally to obtain an inorganic foamed building insulation board. The prepared inorganic foamed building insulation board The length is 450mm; the width is 450mm, and the height is 50mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com