Method for growing titanium dioxide particles on base material

A titanium dioxide and base material technology, applied in the field of photocatalysts, can solve the problems of reduced photocatalytic efficiency, easy fall off of catalysts, and long preparation time, and achieve the effects of wide selection range, low cost of raw materials, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Cut the plant fiber non-woven fabric with a composition of 90% into a size of 6cm×20cm, ultrasonically clean the non-woven fabric with alcohol and deionized water and dry it at 60°C;

[0045] (2) Slowly add 4 mL of tetra-n-butyl titanate dropwise into 40 mL of hydrochloric acid (the molar ratio of hydrogen chloride and deionized water is 1:30), stir while adding dropwise, and stir until the solution is clear to obtain a hydrothermal reaction solution;

[0046] (3) Put the non-woven fabric into a 50mL reaction kettle, pour 40mL of hydrothermal reaction solution;

[0047] (4) Put the reaction kettle into the oven, set the temperature to 90°C, and hold the temperature for 10 hours;

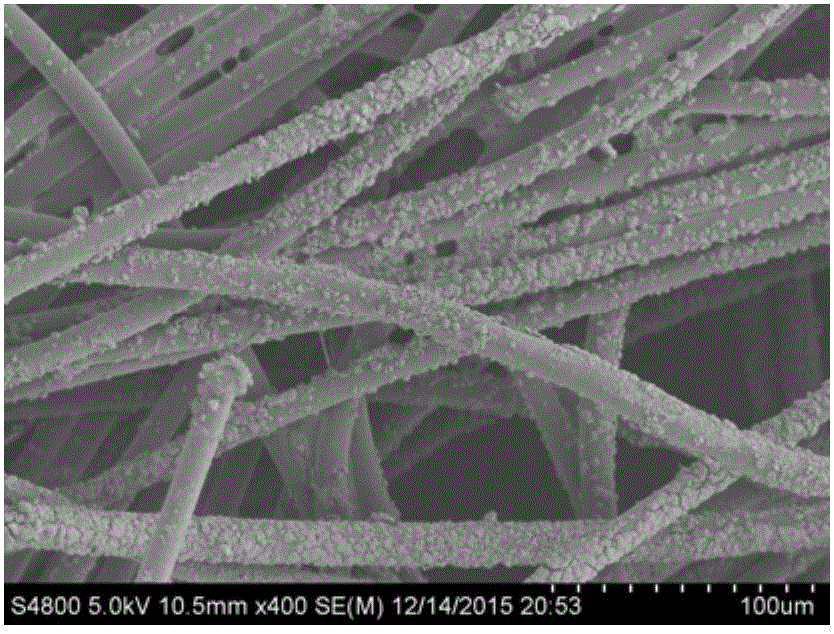

[0048] (5) The obtained non-woven fabric is washed with deionized water several times, and dried at 60°C, and the obtained titanium dioxide particles are as follows: figure 1 shown.

[0049] The titanium dioxide particle prepared in this embodiment is a rutile phase, and the XRD pattern ...

Embodiment 2

[0053] (1) Cut the non-woven fabric with 80% plant fiber into 6cm×20cm size, clean the non-woven fabric ultrasonically with alcohol and deionized water and dry it at 60°C;

[0054] (2) Slowly add 3 mL of tetra-n-butyl titanate dropwise into 40 mL of hydrochloric acid (the molar ratio of hydrogen chloride and deionized water is 1:60), stir while adding dropwise, and stir until the solution is clear to obtain a hydrothermal reaction solution;

[0055] (3) Put the non-woven fabric into a 50mL reaction kettle, pour 40mL of hydrothermal reaction solution;

[0056] (4) Put the reaction kettle into the oven, set the temperature to 100°C, and hold the temperature for 9 hours;

[0057] (5) The obtained non-woven fabric is washed with deionized water several times, and dried at 60°C, and the obtained titanium dioxide particles are as follows: figure 2 shown.

[0058] The titanium dioxide particles prepared in this example are anatase phase, and the XRD pattern of the titanium dioxide...

Embodiment 3

[0060] (1) Cut the non-woven fabric with 70% plant fiber into 6cm×20cm size, clean the non-woven fabric ultrasonically with alcohol and deionized water and dry it at 60°C;

[0061] (2) Slowly add 4 mL of tetra-n-butyl titanate dropwise into 40 mL of hydrochloric acid (the molar ratio of hydrogen chloride and deionized water is 1:45), stir while adding dropwise, and stir until the solution is clear to obtain a hydrothermal reaction solution;

[0062] (3) Put the non-woven fabric into a 50mL reaction kettle, pour 40mL of hydrothermal reaction solution;

[0063] (4) Put the reaction kettle into the oven, set the temperature to 90°C, and hold the temperature for 9 hours;

[0064] (5) The obtained non-woven fabric is washed with deionized water several times, and dried at 60°C, and the obtained titanium dioxide particles are as follows: image 3 shown.

[0065] The titanium dioxide particle prepared in this example is a mixed crystal form of anatase and rutile, and the XRD patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com