Preparation method of low-temperature denitration filter material based on water quenching process

A technology of low-temperature denitrification and water quenching, which is applied in separation methods, chemical instruments and methods, and dispersed particle filtration, etc. It can solve the problem of weak binding force between catalyst and filter bag fiber, poor dispersion of denitrification active components, and reduction of filter cloth fiber strength. and other problems, to achieve the effect of facilitating large-scale industrial production and popularization and application, avoiding spontaneous combustion of filter cloth, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

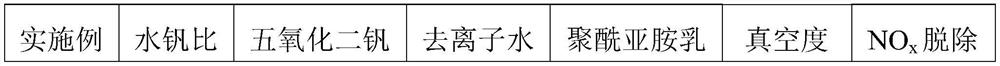

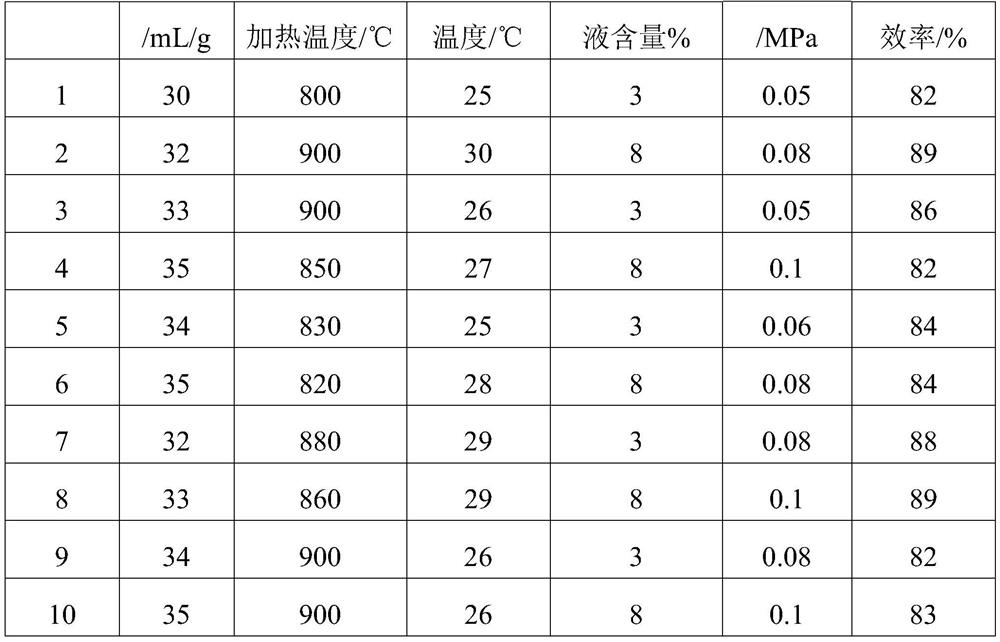

Examples

preparation example Construction

[0025] A method for preparing a denitrification filter material based on a water quenching method in the present invention uses a water quenching method to prepare liquid vanadium pentoxide, and adds organic modifiers and auxiliary agents therein to finally obtain a low-temperature denitrification catalyst precursor emulsion; and then Under negative pressure conditions, the filter cloth is immersed in the emulsion of the precursor of the low-temperature denitration catalyst, and after calcination at 240°C, the low-temperature denitration catalyst is loaded on the polyimide fiber filter cloth to make a low-temperature denitration filter material. The specific steps are as follows:

[0026] (1) Add deionized water into the reaction kettle, heat and melt the vanadium pentoxide powder, pour it into deionized water quickly, and stir it ultrasonically to dissolve.

[0027] (2) Add an organic modifier to the above solution, stir and mix well to obtain a stable vanadium pentoxide emuls...

Embodiment 1

[0046] In this embodiment, the ratio of water to vanadium is 30mL / g, the heating temperature of vanadium pentoxide is 800°C, the temperature of deionized water is 25°C, the content of polyimide emulsion is 3%, and the degree of vacuum is 0.05MPa for specific description. And the low-temperature denitrification filter material obtained under this condition is evaluated on the test bench using simulated flue gas for denitrification performance, that is, the NO and NO in the flue gas at the inlet and outlet of the reactor are tested with a flue gas analyzer. 2 Concentration, calculate NO x The removal efficiency was 82%.

[0047] Under the above parameter conditions, the specific preparation process is as follows,

[0048] (1) Weigh an appropriate amount of vanadium pentoxide powder, put it into a tongs pot, heat it in a muffle furnace to 800° C., and keep it warm for 1 hour to obtain vanadium pentoxide in a molten state.

[0049] (2) Add deionized water into the reactor, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com