Forming method of fin type field-effect transistor

A technology of fin field effect transistors and fins, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of large roughness of gate sidewall line width, etc., to avoid channel length changes, high smoothness, The effect of optimizing electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It can be seen from the background art that the electrical performance of the fin field effect transistor formed in the prior art still needs to be improved.

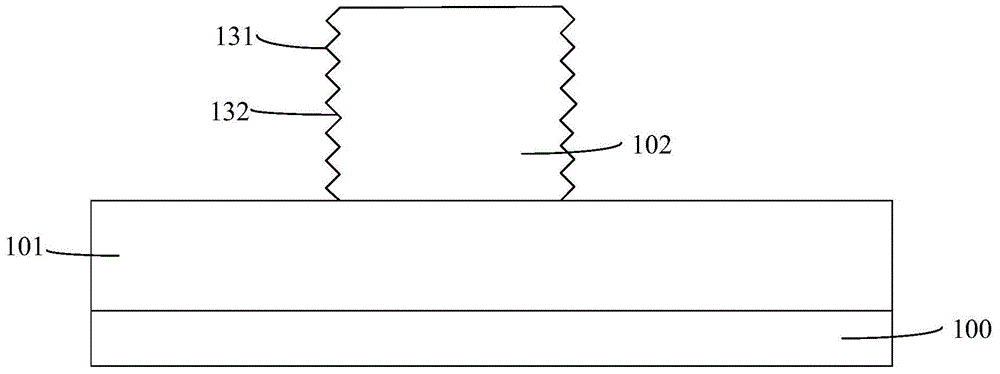

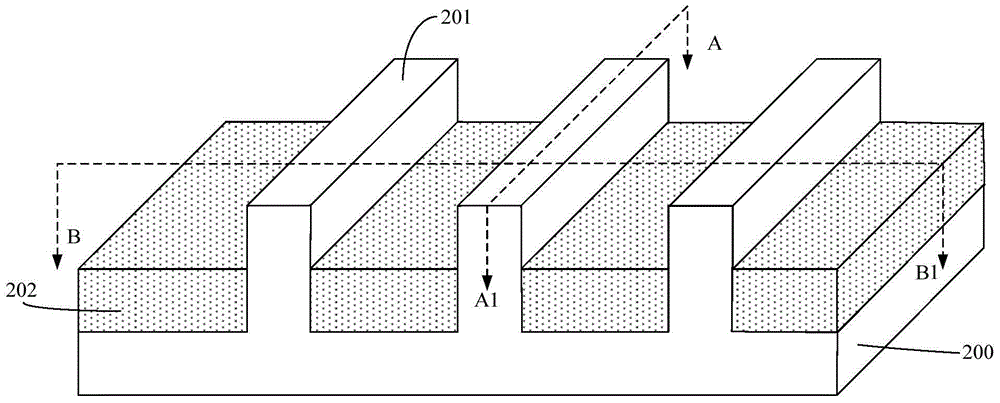

[0031] It is found through research that with the continuous reduction of the size of semiconductor structures, a new method for forming a fin field effect transistor is proposed, including: step S1, providing a substrate and several discrete fins on the surface of the substrate, the substrate A gate film is formed on the bottom surface and the surface of the fin, and the top of the gate film is higher than the top of the fin; step S2, forming several discrete first mask layers on the surface of the gate film, and the first mask The arrangement direction of the layers is consistent with the extending direction of the fins; step S3, using the first mask layer as a mask, etching the gate film until the surface of the substrate is exposed, and then removing the first mask layer; step S4 , forming several discrete se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com