Metal nanowire-antioxidation material composite transparent conductive film and preparation thereof

A metal nanowire, transparent conductive film technology, applied in the direction of metal/alloy conductors, oxide conductors, non-metallic conductors, etc., can solve the problems of decreased electrical conductivity and optical clarity, poisoning of substrate materials, complicated preparation methods, etc. , to achieve the best sheet resistance and transmittance, good chemical stability, and rich material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

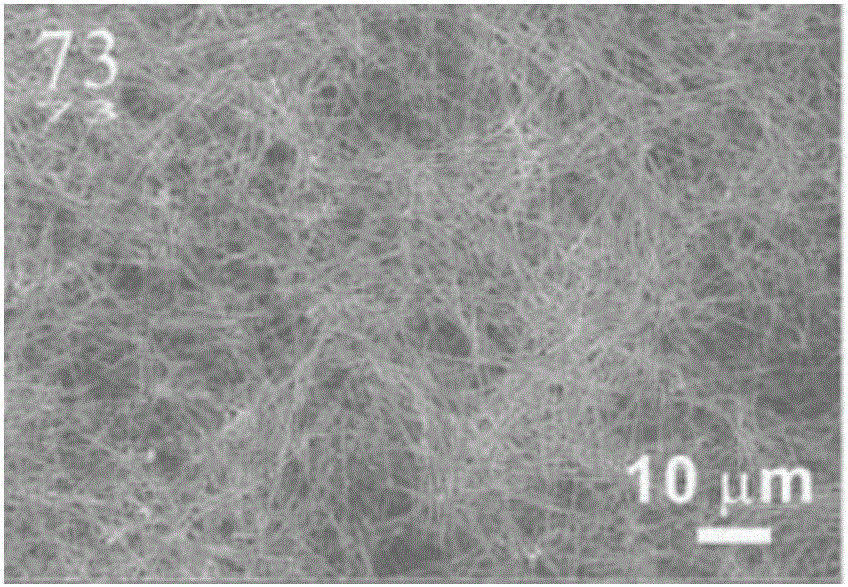

[0044] 0.1 μM AgNO 3 Mix with 0.1 micromole of copper chloride, add appropriate amount of ethylene glycol and appropriate amount of PVP with appropriate molecular weight, heat to 140°C, and keep for 40 minutes to obtain silver nanowires with a diameter of 40 nanometers and a length of 18-25 microns. Add 40-mesh flake graphite powder into the aqueous solution, and stir with a high-speed disperser to obtain a graphene aqueous solution, wherein in the graphene solution, graphene sheets below 5 layers occupy 60-70%.

[0045] A 50-micron PET film was hydroxylated with 20% sodium hydroxide, then simultaneously modified with a mercaptosilane coupling agent and an aminosilane coupling agent, and coated with silver by spin coating (large-area films are also prepared by ramp coating). The nanowire dispersion liquid was dried at 120° C., and then the graphene dispersion liquid was spin-coated and treated at 180° C. for 1 minute to obtain a silver nanowire graphene transparent conductive ...

Embodiment 2

[0047] The silver nanowire dispersion was prepared according to the method in Example 1. Use concentrated sulfuric acid and potassium permanganate to oxidize 50-mesh flake graphite powder, obtain a graphene oxide solution after ultrasonic dispersion, and reduce it with hydrazine hydrate to form a graphene solution.

[0048] The 50-micron flexible glass is treated with a mixture of concentrated sulfuric acid and hydrogen peroxide, then hydroxylated, then modified with mercaptosilane and aminosilane at the same time, and then spin-coated (large-area films can also be coated with curtain coating or gravure coating) Preparation) Coating the silver nanowire dispersion, treating at 120°C for one minute, then spin-coating the graphene dispersion, and treating at 180°C for one minute. The silver nano-graphene wire composite transparent conductive film has a square resistance of 50 ohms, a light transmittance of 89%, and a conductivity drop of less than 0.2% in 200 days in a pure oxyge...

Embodiment 3

[0050] The silver nanowire dispersion was prepared according to the method in Example 1, the zinc oxide nanoparticle sol was purchased, and the two dispersions were mixed.

[0051] The 50-micron flexible glass is treated with a mixture of concentrated sulfuric acid and hydrogen peroxide, then hydroxylated, modified with mercaptosilane and aminosilane at the same time, and then spin-coated (large-area films can also be coated with curtain coating or gravure coating) Preparation) Coating the mixed dispersion of silver nanowires and nano-zinc oxide, treating at 120°C for one minute, and treating at 180°C for one minute, the sheet resistance of the composite transparent conductive film is 50 ohms, and the light transmittance is 92%, under the pure oxygen environment of 200°C After 200 days, the conductivity drops below 0.2%, and there are conductive points down to the level of 1 nanometer; after bending 10,000 times (diameter 2mm), the conductivity drops below 2%, and the haze is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com