Coating method for neodymium iron boron magnet electrophoresis film and coated neodymium iron boron magnet

A coating method, NdFeB technology, applied in the direction of electrolytic coating, electrophoretic plating, magnetic objects, etc., can solve the problems of poor bonding force, difficulty, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] NdFeB magnet sample specification: R24×r43.8×L24×W30.69

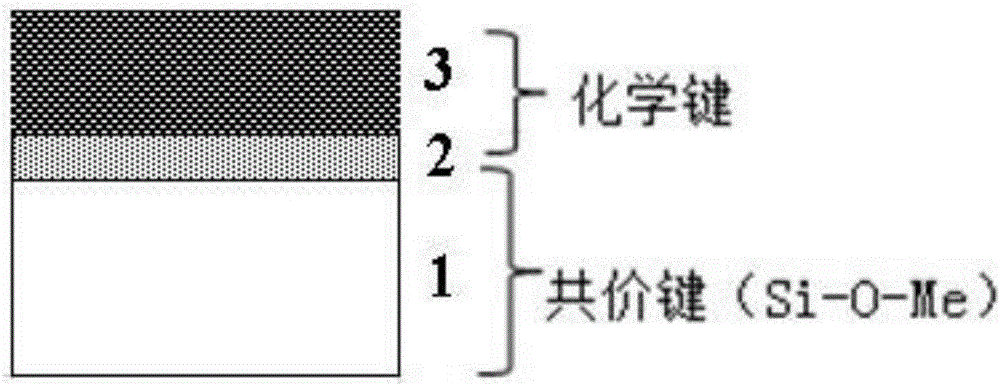

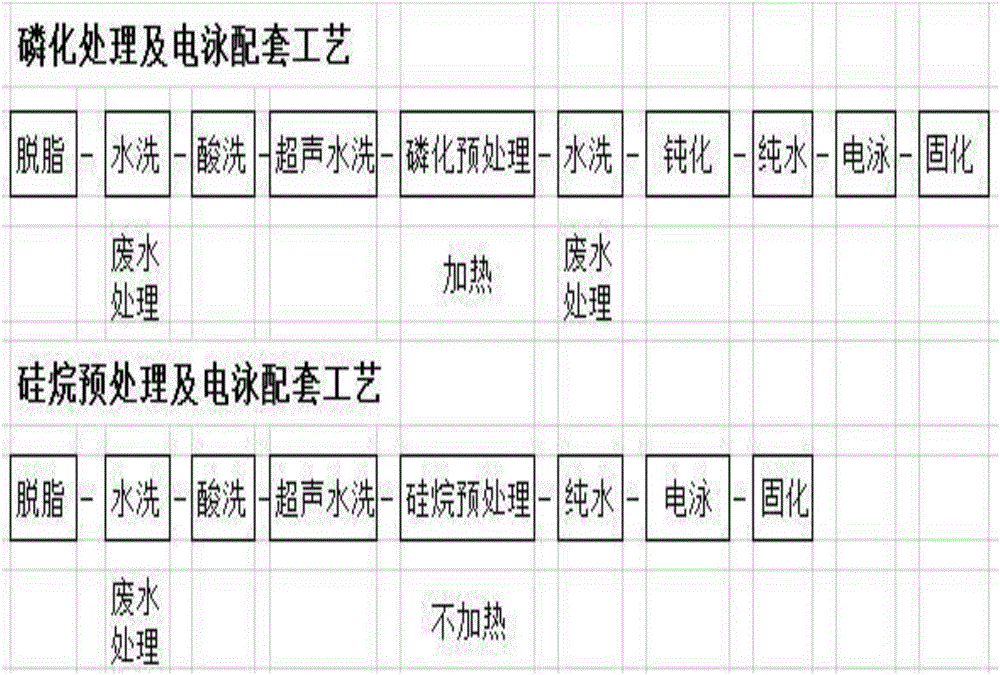

[0068] The NdFeB magnets that have been degreased, washed with water, pickled or ultrasonically washed in sequence are subjected to silane pretreatment, and then washed with water to obtain a magnet compounded with a silane film.

[0069] Among them, the pickling is pickling with nitric acid, and about 20 μm is washed off on one side in the thickness direction.

[0070] Silane pretreatment: In silane solution, a silane conversion film is formed on the surface of the pretreated NdFeB magnet. Silane treatment conditions: temperature: 23°C, time: 90 seconds;

[0071] Then, electrophoretic coating is performed on the magnet compounded with the silane film obtained in the above steps, and then solidified to obtain a coated NdFeB magnet.

[0072] For washing conditions, see Table 1. Table 1 is a comparison between the washing process of the coating method provided by the present invention and the washing process of t...

Embodiment 2

[0086] NdFeB magnet sample specification: R24×r43.8×L24×W30.69

[0087] The NdFeB magnets that have been degreased, washed with water, pickled or ultrasonically washed in sequence are subjected to silane pretreatment, and then washed with water to obtain a magnet compounded with a silane film.

[0088] Among them, the pickling is pickling with nitric acid, and about 20 μm is washed off on one side in the thickness direction.

[0089] Silane pretreatment: In silane solution, a silane conversion film is formed on the surface of the pretreated NdFeB magnet. Silane treatment conditions: temperature: 23°C, time: 90 seconds;

[0090] Then, electrophoretic coating is performed on the magnet compounded with the silane film obtained in the above steps, and then solidified to obtain a coated NdFeB magnet.

[0091] For washing conditions, see Table 1. Table 1 is a comparison between the washing process of the coating method provided by the present invention and the washing process of t...

Embodiment 3

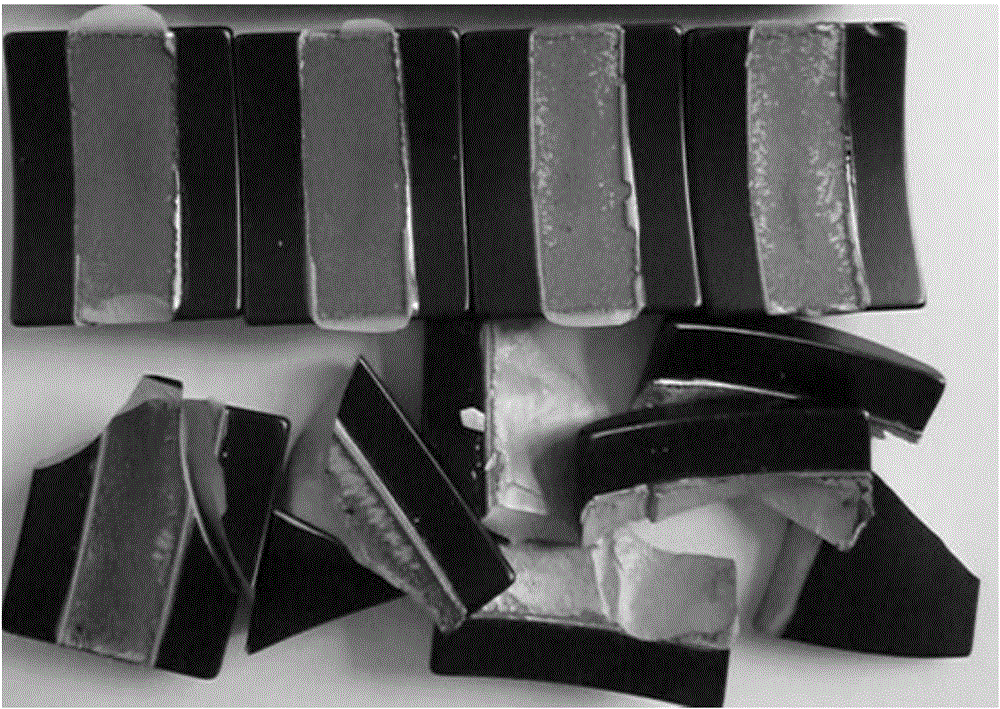

[0106] NdFeB magnet sample specification: 55*28*1.5

[0107] The NdFeB magnets that have been degreased, washed with water, pickled or ultrasonically washed in sequence are subjected to silane pretreatment, and then washed with water to obtain a magnet compounded with a silane film.

[0108] Among them, the pickling is pickling with nitric acid, and about 20 μm is washed off on one side in the thickness direction.

[0109] Silane pretreatment: In silane solution, a silane conversion film is formed on the surface of the pretreated NdFeB magnet. Silane treatment conditions: temperature: 23°C, time: 90 seconds;

[0110] Then, electrophoretic coating is performed on the magnet compounded with the silane film obtained in the above steps, and then solidified to obtain a coated NdFeB magnet.

[0111] For washing conditions, see Table 1. Table 1 is a comparison between the washing process of the coating method provided by the present invention and the washing process of the original...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com