High-dispersity polyimide/nanoparticle composite thin film and preparation method thereof

A nanoparticle and polyimide technology, which is applied in the field of highly dispersive polyimide/nanoparticle composite films and their preparation, can solve problems such as field limitations, and achieve excellent mechanical properties, good high temperature resistance, and good chemical properties. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

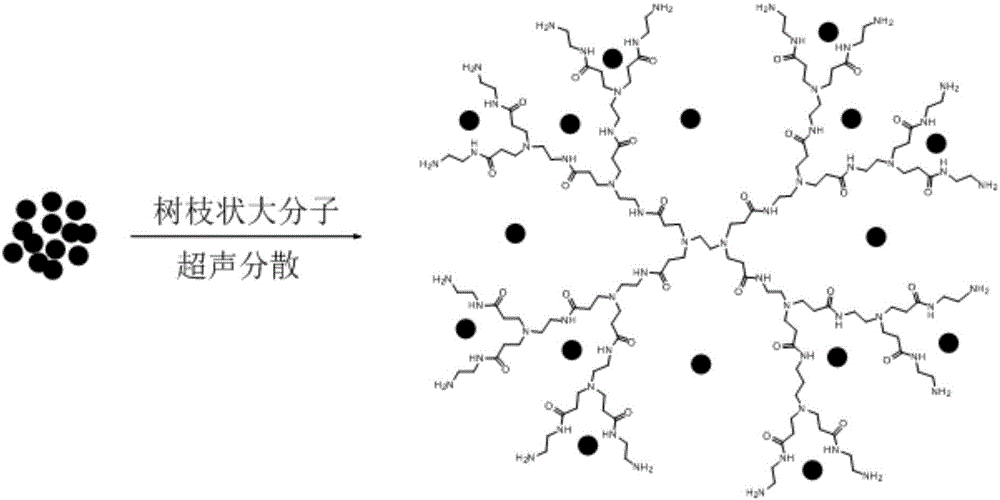

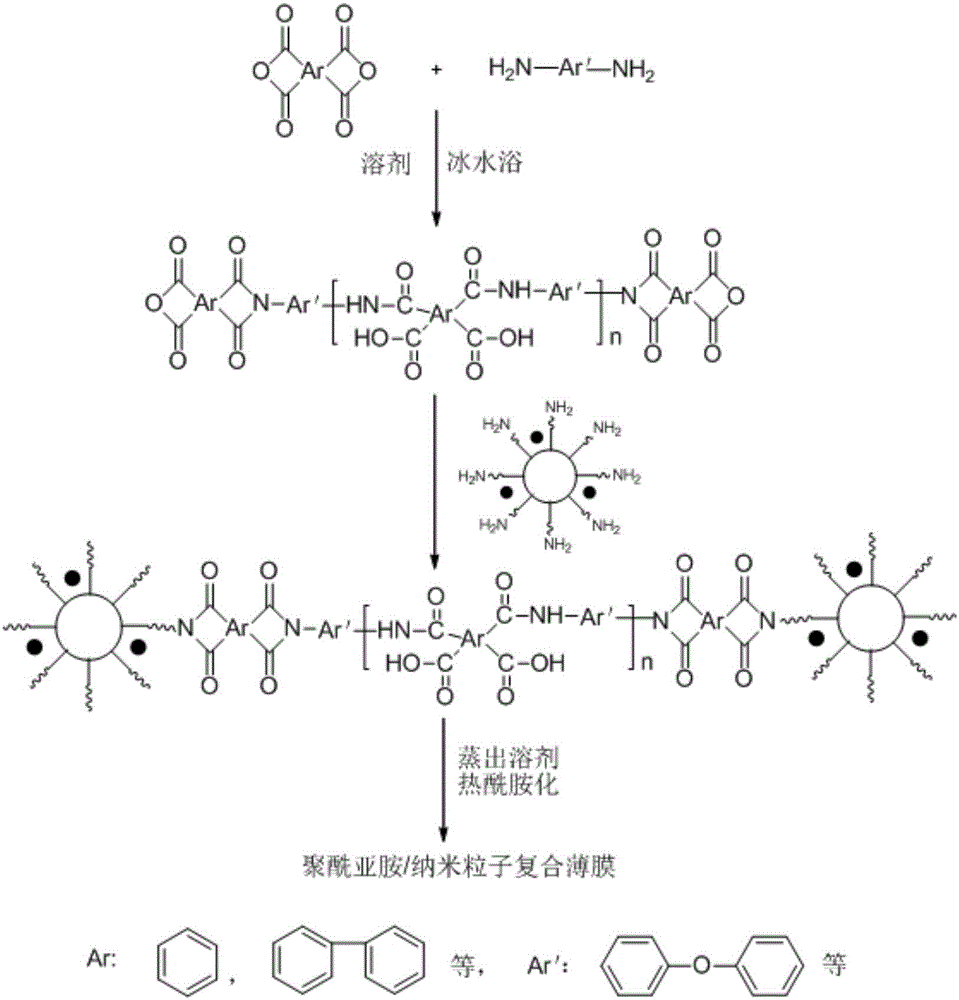

[0036] Add 0.20g of nano-barium titanate to 5.62g of the first-generation PAMAM solution, and ultrasonically disperse for 30min, such as figure 1 shown. Under nitrogen protection, 2.2248g of pyromellitic dianhydride and 2.0023g of 4,4'-diaminodiphenyl ether were added to 28.18g of N-methylpyrrolidone to form a solid content of 15% (wt / wt ) solution, and reacted in an ice-water bath for 24h to obtain an anhydride-terminated polyamic acid solution. Add 2.91 g of the first-generation PAMAM solution dispersed with nanobarium titanate particles into the above polyamic acid solution, ultrasonically disperse for several minutes, and continue to react for 12 hours to obtain a polyamic acid viscous solution. Take an appropriate amount of polyamic acid viscous liquid and pour it on a clean glass plate mold. Put the mold into a vacuum drying oven, dry in vacuum at 80° C. for 2 hours, and dry in vacuum at 150° C. for 2 hours to obtain a polyamic acid gel film. Continue to heat up to 20...

Embodiment 2

[0038]Add 0.3g of nano-silver particles into 5.45g of the second-generation PAMAM solution, and ultrasonically disperse for 40min. Under nitrogen protection, 2.2466g of pyromellitic dianhydride and 2.0023g of 4,4'-diaminodiphenyl ether were added to 42.49g of N,N-dimethylacetamide to form a solid content of 10%. (wt / wt) solution, and reacted in an ice-water bath for 23h to obtain an anhydride-terminated polyamic acid solution. Add 2.46 g of the second-generation PAMAM solution dispersed with nano-silver particles into the above polyamic acid solution, ultrasonically disperse for several minutes, and continue to react for 11 hours to obtain a polyamic acid viscous liquid. Take an appropriate amount of polyamic acid viscous liquid and pour it on a clean glass plate mold. Put the mold into a vacuum drying oven, dry in vacuum at 80°C for 2 hours, and dry in vacuum at 150°C for 2 hours, and remove the solvent to obtain a polyamic acid gel film. After continuing to heat up to 200°...

Embodiment 3

[0040] 0.40 g of nano-silica particles were added to 3.31 g of the third-generation PAMAM solution, and ultrasonically dispersed for 30 min. Under the protection of nitrogen, 2.2903g of pyromellitic dianhydride and 2.0023g of 4,4'-diaminodiphenyl ether were added to 28.62g of N,N-dimethylformamide to form a solid content of 15%. (wt / wt) solution, and reacted in an ice-water bath for 22h to obtain an anhydride-terminated polyamic acid solution. Add 1.95 g of the third-generation polyamide-amine solution dispersed with nano-silica to the above polyamic acid solution, ultrasonically disperse for several minutes, and continue to react for 13 hours to obtain a polyamic acid viscous liquid. Take an appropriate amount of polyamic acid viscous liquid and pour it on a clean glass plate mold. Put the mold into a vacuum drying oven, dry in vacuum at 80°C for 2 hours, and dry in vacuum at 150°C for 2 hours, and remove the solvent to obtain a polyamic acid gel film. After continuing to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com