Carbohydrate ester modified polycarboxylate superplasticizer and preparation method thereof

A technology of esterification and polycarboxylic acid, which is applied in the field of construction admixtures, can solve problems such as easy mildew of construction admixtures, segregation of concrete aggregate and slurry, negative impact on building strength, etc., to achieve outstanding substantive features, The effect of prolonging the initial setting time and prolonging the final setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

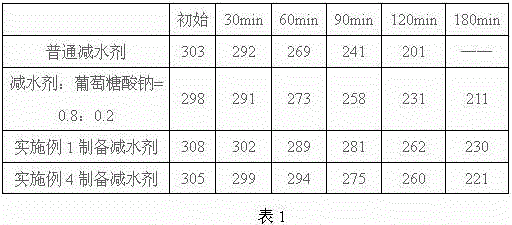

Examples

preparation example Construction

[0019] The first aspect of the present invention provides a method for preparing a solid polycarboxylate water reducer, comprising the following steps:

[0020] (1) Add sugar compounds, such as glucose, maltose, sucrose, or their mixtures, into the reaction vessel; add unsaturated carboxylic acid compounds, such as acrylic acid and methacrylic acid, stir rapidly, and heat up to 60 ° C ~ 90 ° C, respectively Add concentrated sulfuric acid liquid and a polymerization inhibitor such as hydroquinone, p-quinone or a mixture thereof. Under the condition of mechanical stirring, react for 2 hours to 6 hours.

[0021] (2) Combine the esterified product synthesized in step (1) with unsaturated alcohol polyether, such as isopentenyl polyether (TPEG), isobutenyl polyether (HPEG), acryl polyether (APEG), etc., and deionized water Add the reaction device, add initiators, such as ammonium persulfate, sodium persulfate, hydrogen peroxide, peracetic acid, etc., raise the temperature to 40 ° C...

Embodiment 1

[0024] Add 1000g of glucose and 750g of acrylic acid to the reaction vessel, stir rapidly, raise the temperature to 65°C, add 15g of concentrated sulfuric acid liquid, and add 3.5g of hydroquinone. The reaction was carried out for 4 hours under mechanical stirring. Perform necessary purification treatment on the esterified product prepared above.

[0025] Add 50 g of the above-prepared esterified product, 1000 g of isopentenyl polyether (TPEG) with a number average molecular weight of 2400 and deionized water into the reaction device, raise the temperature to 60 ° C under mechanical stirring conditions, and add 12 g of ammonium persulfate as a copolymerization For the initiator of the reaction, 120 g of acrylic acid was added dropwise at a constant speed, and the dropwise addition time was 4 hours. After the reaction, use aqueous sodium hydroxide solution to adjust the pH value to 5.0-7.5, and add deionized water to adjust the concentration to 20%.

Embodiment 2

[0027] Add 1000g of sucrose and 700g of methacrylic acid to the reaction vessel, stir rapidly, raise the temperature to 70°C, add 20g of concentrated sulfuric acid liquid, and add 4.5g of hydroquinone. The reaction was carried out for 3 hours under the condition of mechanical stirring. Perform necessary purification treatment on the esterified product prepared above.

[0028] Add 60g of the above-prepared esterified product, 1000g of isobutenyl polyether (HPEG) with a number average molecular weight of 2400 and deionized water into the reaction device, raise the temperature to 55°C under mechanical stirring, and add 15g of sodium persulfate as a starting point for the copolymerization reaction. Initiator, 135g of methacrylic acid was added dropwise at a constant speed, and the dropping time was 4.5 hours. After the reaction, use aqueous sodium hydroxide solution to adjust the pH value to 5.0-7.5, and add deionized water to adjust the concentration to 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com