Room temperature ferromagnetic semiconductor material MnSiP2 and preparation method and applications thereof

A semiconductor, room temperature technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem of low Curie temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] According to the molar ratio of Mn:Si:P=1:1:2.0, three simple raw materials of Mn, Si and P were weighed respectively, and the raw materials were ground evenly in an agate mortar, put into a quartz tube, and vacuumed 3×10 -4 After Pa, seal and fire the quartz tube. Put the quartz tube into a high-temperature tube furnace, and use staged heating. First, raise the temperature to 450°C at a rate of 30°C / hour, keep the temperature at a constant temperature for 15 hours, continue to heat up to a reaction temperature of 950°C, and react at a constant temperature for 20 hours. Then, after 50 Hours slowly cooled to room temperature. Open the quartz tube, take out the well-crystallized block, clean it with deionized water, and place it in an oven for drying to obtain pure phase MnSiP 2 Magnetic semiconductor materials.

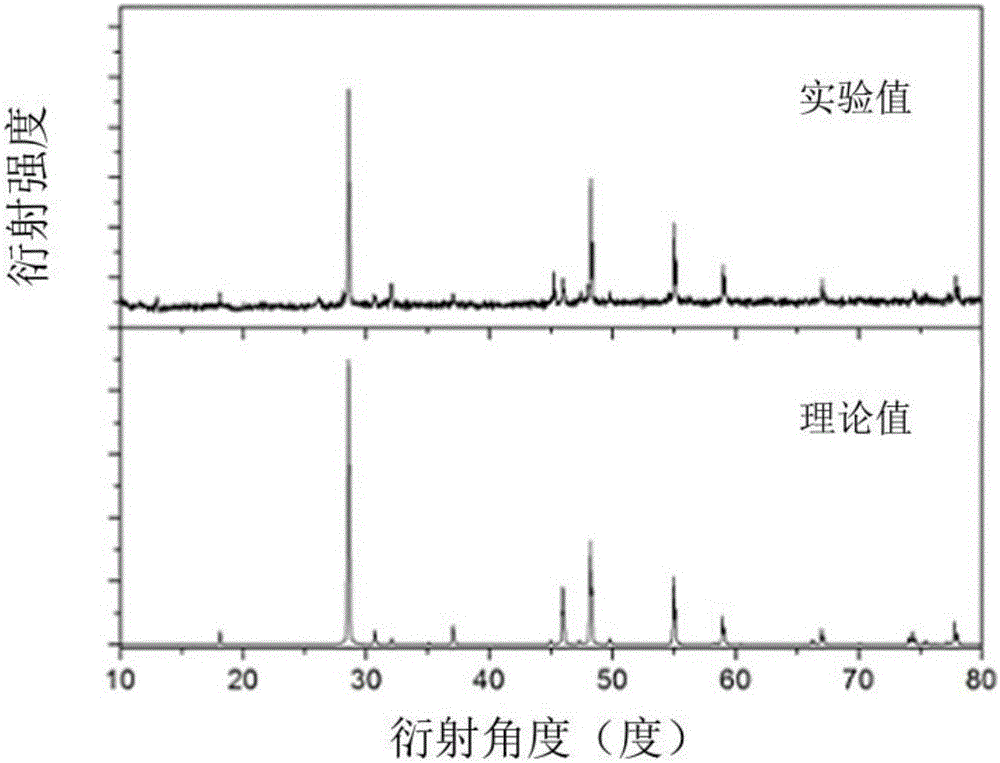

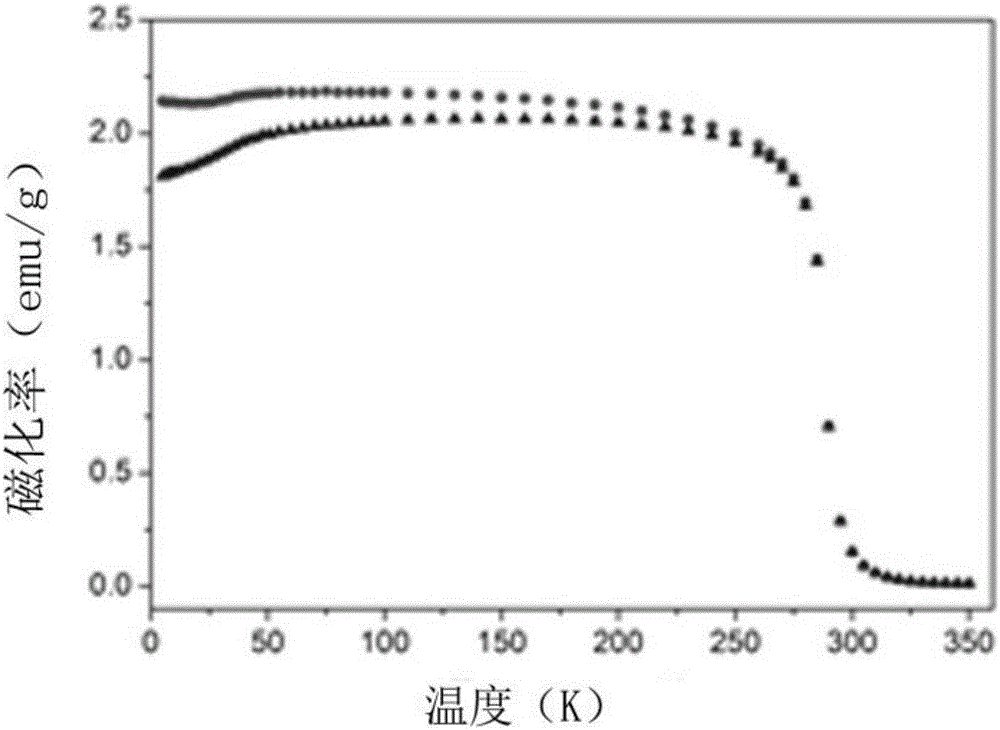

[0016] The MnSiP obtained through high temperature synthesis in this example 2 The powder X-ray diffraction pattern and temperature-varying magnetic suscepti...

Embodiment 2

[0018] According to the molar ratio of Mn:Si:P=1:1:2.3, weigh the three simple raw materials of Mn, Si and P respectively, grind the raw materials evenly in the agate mortar, put them into the quartz tube, and vacuumize 4×10 -4 After Pa, seal and fire the quartz tube. Put the quartz tube into a high-temperature tube furnace, and use a staged temperature rise. First, raise the temperature to 500°C at a rate of 40°C / hour, keep the temperature constant for 20 hours, continue to heat up to the reaction temperature of 1000°C, and react at a constant temperature for 25 hours. Then, after 80 Hours slowly cooled to room temperature. Open the quartz tube, take out the well-crystallized block, clean it with deionized water, and place it in an oven for drying to obtain pure phase MnSiP 2 Magnetic semiconductor materials.

Embodiment 3

[0020] According to the molar ratio of Mn:Si:P=1:1:2.5, three simple raw materials of Mn, Si and P were weighed respectively, and the raw materials were ground evenly in an agate mortar, put into a quartz tube, and vacuumed 5×10 -4 After Pa, seal and fire the quartz tube. Put the quartz tube into a high-temperature tube furnace, and adopt a staged temperature rise. First, raise the temperature to 480°C at a rate of 50°C / hour, keep the temperature for 18 hours, continue to heat up to the reaction temperature of 1050°C, and react at a constant temperature for 30 hours. Then, after 100 Hours slowly cooled to room temperature. Open the quartz tube, take out the well-crystallized block, clean it with deionized water, and place it in an oven for drying to obtain pure phase MnSiP 2 Magnetic semiconductor materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com