Preparation method of fine elemental spherical metal powder particles for 3D printing

A metal powder, 3D printing technology, used in metal processing equipment, transportation and packaging, additive processing, etc., can solve the problems of low purity of metal or alloy powder, low utilization rate of raw materials, uncontrollable particle size, etc., and achieve low oxygen content, increased yield, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

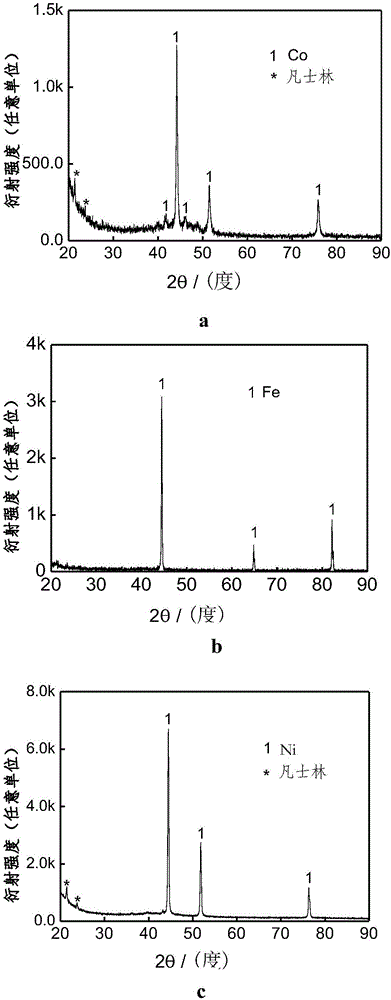

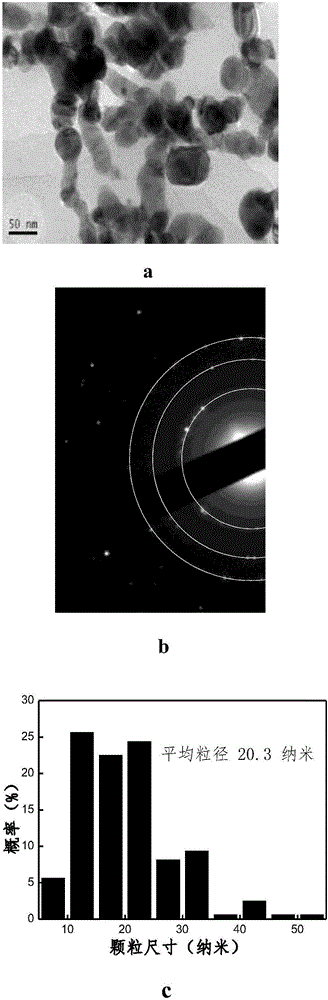

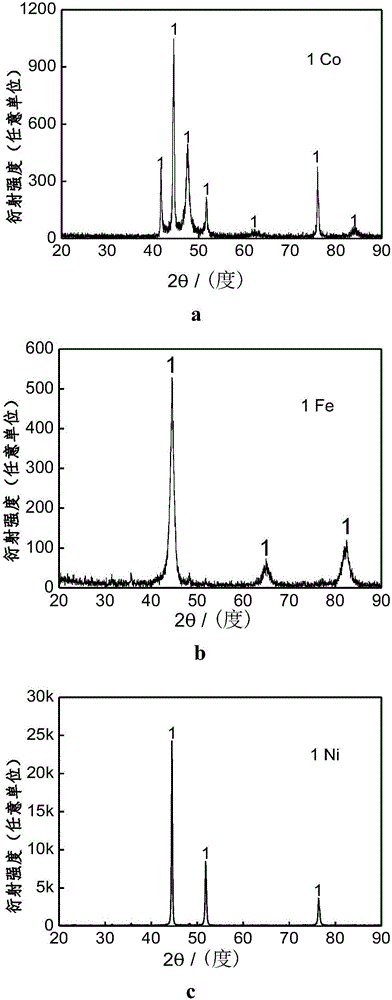

Embodiment 1

[0019] Example 1. Using the raw material high-purity cobalt block (purity 99.99wt%) as the anode and tungsten as the cathode, first evacuate and introduce argon until the vacuum pressure reaches 0.04MPa, and form a high-strength arc through the discharge effect. After the arc is completed Introduce hydrogen until the vacuum pressure reaches 0.03MPa, and form solid high-purity cobalt nanoparticles by evaporating metal gas atoms and condensing them. The phase detection pattern is as follows: figure 1 a, the microscopic appearance is as figure 2 a; Using the existing patented technology (authorized patent number 201010219344.3), the cobalt nanoparticles are mixed with polyvinyl alcohol, polyethylene glycol and deionized water, then ball milled for 60 minutes, and then mechanically stirred for 20 minutes to obtain a uniform and stable suspension slurry. , using closed-circulation spray drying equipment for agglomeration and granulation to obtain spherical cobalt particles of 20 t...

Embodiment 2

[0020] Example 2. The raw material high-purity iron block (purity 99.99wt%) was used as the anode, and argon gas was first introduced until the vacuum pressure reached 0.05MPa, and a high-strength arc was formed by discharge action. After the arc was completed, hydrogen was introduced until the vacuum pressure reached 0.02 MPa, solid high-purity iron nanoparticles are formed by the condensation of vaporized metal gas atoms, and the phase detection pattern is as follows figure 1 b, The results of the selected area electron diffraction pattern and the crystal plane calibration of the cubic crystal structure are as follows figure 2 b; Using the existing patented technology (authorized patent number 201010219344.3), the iron nanoparticles were mixed with polyvinyl alcohol, polyethylene glycol and deionized water, ball milled for 70 minutes, and then mechanically stirred for 30 minutes to obtain a uniform and stable suspension slurry. The closed-loop spray drying equipment is used...

Embodiment 3

[0021]Example 3. The raw material high-purity nickel block (purity 99.99wt%) was used as the anode, and argon gas was first introduced until the vacuum pressure reached 0.06MPa, and a high-strength arc was formed through the discharge action. After the arc was completed, hydrogen was introduced until the vacuum pressure reached 0.01 MPa, through the condensation of vaporized metal gas atoms to form solid high-purity nickel nanoparticles, the phase detection pattern is as follows figure 1 c, The statistical results of particle size distribution of nano-nickel powder particles are as follows figure 2 c; using the existing patented technology (authorized patent number 201010219344.3), the nickel nanoparticles are mixed with polyvinyl alcohol, polyethylene glycol and deionized water, then ball milled for 80min, and then mechanically stirred for 40min to obtain a uniform and stable suspension slurry, Agglomeration and granulation are carried out with closed-circulation spray dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com