Binder, and preparation method and application thereof

A binder and reaction technology, applied in the field of binder and preparation of secondary battery, can solve the problem of not being able to adapt well to the volume change of electrode active materials, insufficient resistance to electrode buffer characteristics, and decrease in battery cycle stability, etc. problem, to achieve the effect of facilitating large-scale implementation, improving the overall electrochemical performance, and outstanding cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 binding agent

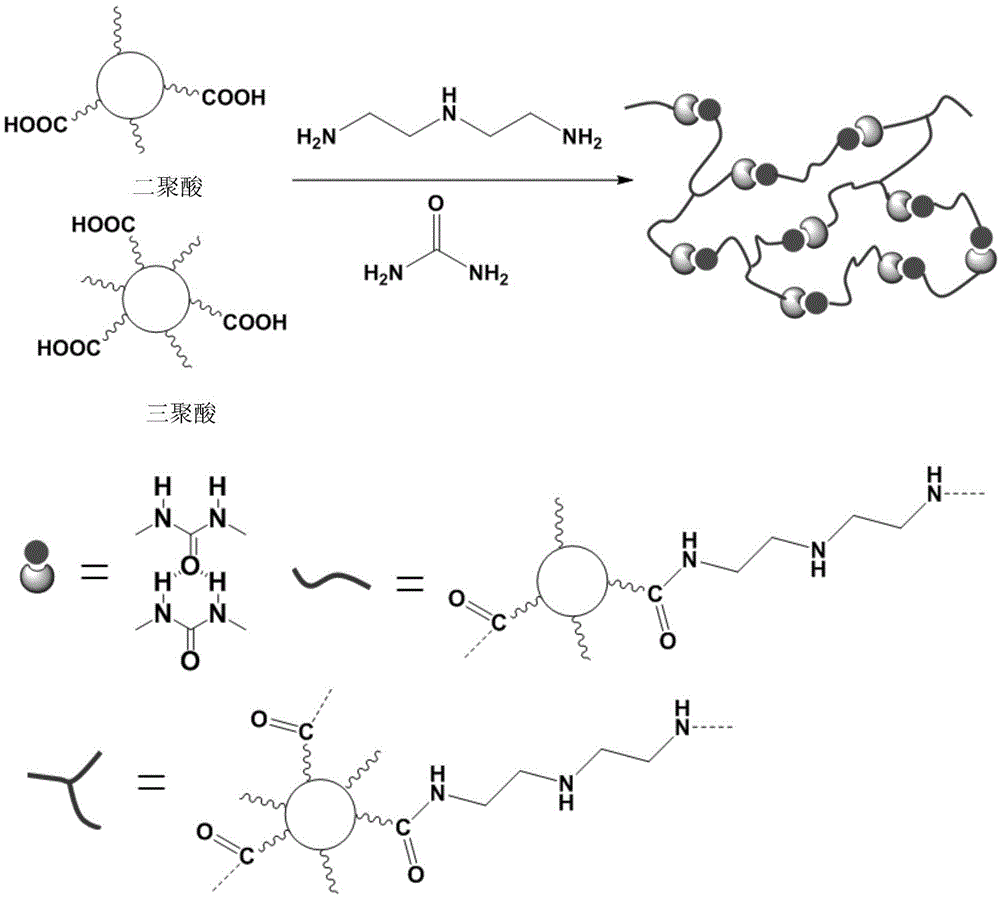

[0037] see figure 1 , the binder is synthesized in two steps, as follows:

[0038] The first step: under nitrogen protection conditions, get 4.2g dimer acid (HJ-156, Shandong Huijin Chemical Co., Ltd., mainly containing 75-82% dimer acid and 15-22% trimer acid) and 1.7g diethylene The triamine was kept at 160 degrees (if not specified below, all refer to ℃) for 24 hours, the reaction product was dissolved in chloroform, the solution was washed repeatedly with a mixture of water / methanol (volume ratio of 2 / 1), and finally the chloroform solvent was spin-dried to obtain oligomers.

[0039] Step 2: Under the condition of nitrogen protection, take 3g of oligomer and 0.7g of urea to react at 140°C for 6 hours, wash thoroughly with water or a water-alcohol mixed solvent for 3 to 5 times of purification, and obtain a polyamide resin with self-repairing function Electrode binder (SHP).

[0040] The binder is a bright yellow, t...

Embodiment 2 Embodiment 1

[0041] One of the battery application schemes of the binder obtained in Example 2 Example 1

[0042] Get carbon black (Super-P) and commercial sulfur mix (mass ratio is 2:3), under the protection condition of argon in the sealed reactor, 155 ℃ through the diffusion reaction of molten sulfur for 12 hours, obtain positive electrode active material (CB / S). CB / S and carbon black (conductive agent) were mixed with different binders (SHP, polyvinylidene fluoride (PVDF) and styrene-butadiene rubber-sodium carboxymethyl cellulose (SBR-CMC)) at a ratio of 7:2 The mass ratio of : 1 is mixed evenly, and the positive electrode slurry is prepared, and the positive electrode slurry is evenly coated on the aluminum foil, dried in vacuum at 50 degrees for 24 hours, punched into pieces with a diameter of 15mm as the positive electrode, and metal lithium as the negative electrode, adding 1% LiNO3 lithium bis(trifluoromethylsulfonate)imide (LiTFSI) in 1,3-dioxolane (DOL) / ethylene glycol dimeth...

Embodiment 3 Embodiment 1

[0043] Example 3 The second battery application scheme of the binder obtained in Example 1

[0044]Under the condition of ammonia gas, take graphene oxide powder and react in the quartz tube of tube furnace at 800 degrees for 1 hour to obtain nitrogen-doped graphene (N-G), N-G and commercial sulfur are mixed (mass ratio is 2:3), sealed Under the protection condition of argon in the reaction kettle, the positive electrode active material (N-G / S) was obtained through the diffusion reaction of molten sulfur at 155 degrees for 12 hours. N-G / S, carbon black (conductive agent) and different binders (SHP, PVDF and SBR-CMC) were mixed uniformly at a mass ratio of 7:2:1 to prepare positive electrode slurry, and the positive electrode slurry was evenly coated on On the aluminum foil, vacuum dry at 50 degrees for 24 hours, die into a sheet with a diameter of 15mm as the positive electrode, metal lithium as the negative electrode, add 1% LiNO3 LiTFSI DOL / DME (volume ratio is 1:1) solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com