Positive pole piece of lithium-sulphur battery and preparation method thereof

A technology for positive pole pieces and sulfur batteries, which is applied in the field of lithium-sulfur battery positive pole pieces and its preparation, can solve problems such as L-cysteine that have not been seen, and achieve improved electrochemical reversibility and redox properties, Improved electrochemical performance and improved cycle capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

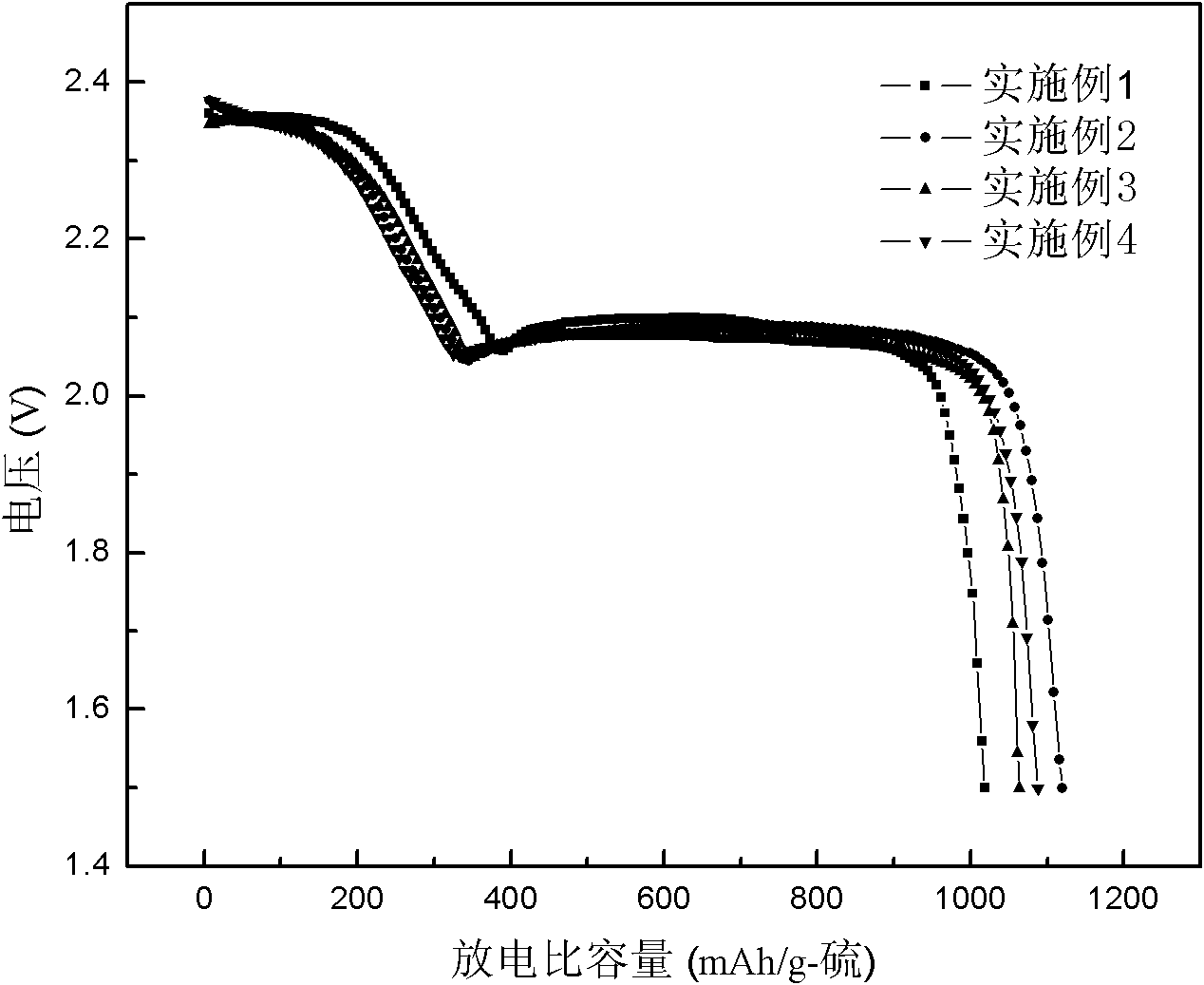

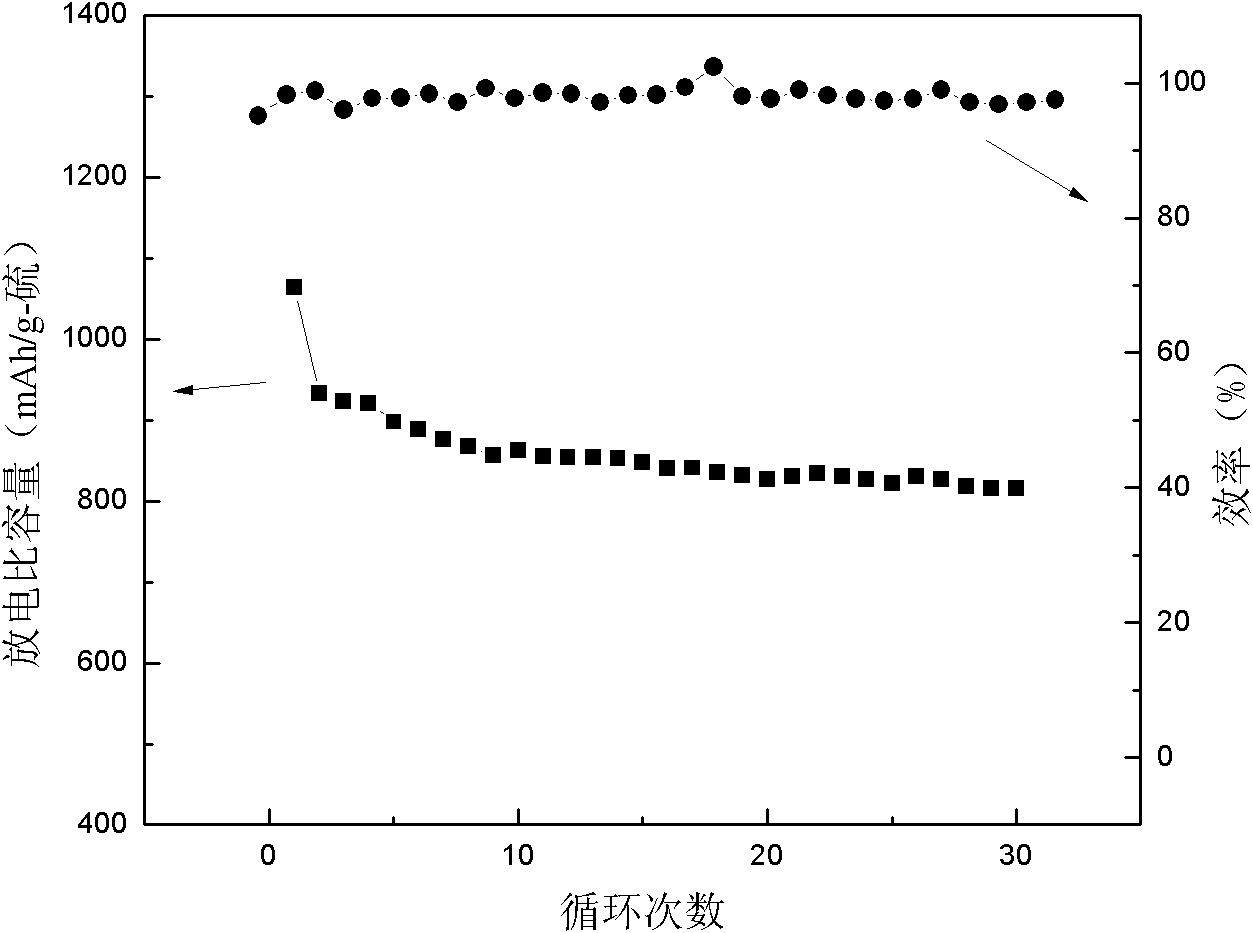

Embodiment 1

[0026] A gelatin aqueous solution with a mass percent concentration of 2% was prepared, and then L-cysteine was added, and the mass ratio of L-cysteine to gelatin was 0.1:10. Use 1mol / L KOH solution to adjust pH=7, set aside.

[0027] Preparation of positive electrode sheet: Grind sublimated sulfur and acetylene black evenly, and then add them to the above-mentioned mixed solution of L-cysteine and gelatin. The mass ratio of sublimated sulfur, acetylene black, gelatin, and cysteine is 60:30:10:0.1, continue to grind, and make a uniform positive electrode slurry, which is coated on the aluminum foil current collector by the scraper method, and after air-drying at room temperature, the Dry it in a vacuum oven for 10 hours, and press it into a disc with a diameter of 1.2 cm.

[0028] Use the pole piece prepared above as the positive electrode, the negative electrode is lithium metal, the diaphragm is made of polypropylene film, and the electrolyte is 1mol / L LiClO 4 solu...

Embodiment 2

[0030] A gelatin aqueous solution with a mass percent concentration of 2% was prepared, and then L-cysteine was added, and the mass ratio of L-cysteine to gelatin was 0.1:10. Use 1mol / L KOH solution to adjust pH=10, set aside.

[0031]Preparation of positive electrode sheet: Grind sublimated sulfur and acetylene black evenly, and then add the above mixed solution of L-cysteine and gelatin. The mass ratio of sublimated sulfur, acetylene black, gelatin, and cysteine is 60:30:10:0.1. Continue to grind to make a uniform positive electrode slurry, which is coated on the aluminum foil current collector by the scraper method. After air-drying at room temperature, the Dry it in a vacuum oven for 10 hours, and press it into a disc with a diameter of 1.2 cm.

[0032] Use the pole piece prepared above as the positive electrode, the negative electrode is lithium metal, the diaphragm is made of polypropylene film, and the electrolyte is 1mol / L LiClO 4 solution, the solvent is DME...

Embodiment 3

[0034] Prepare an aqueous gelatin solution with a mass percent concentration of 3%, and then add L-cysteine, and the mass ratio of L-cysteine to gelatin is 0.2:15. Adjust the pH to 7 with 0.1mol / L LiOH solution and set aside.

[0035] Preparation of the positive pole piece: Preparation of the positive pole piece: grind the sublimated sulfur and acetylene black evenly and add them into the above-mentioned mixed solution of L-cysteine and gelatin. The mass ratio of sublimated sulfur, acetylene black, gelatin, and cysteine is 60:40:15:0.2, continue to grind, and make a uniform positive electrode slurry, which is coated on the aluminum foil current collector by the scraper method, and after air-drying at room temperature, in Dry it in a vacuum oven for 10 hours, and press it into a disc with a diameter of 1.2 cm.

[0036] Use the pole piece prepared above as the positive electrode, the negative electrode is lithium metal, the diaphragm is made of polypropylene film, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com