Preparation method for graphite-phase carbon nitride thin film modified electrode

A graphite-phase carbon nitride and modified electrode technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve problems such as uneven graphite-phase carbon nitride powder, unsatisfactory thermoelectric performance, and unstable electrode materials. Achieve good application potential, improve thermoelectric performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of graphite phase carbon nitride film modified electrode of the present invention, comprises the following steps:

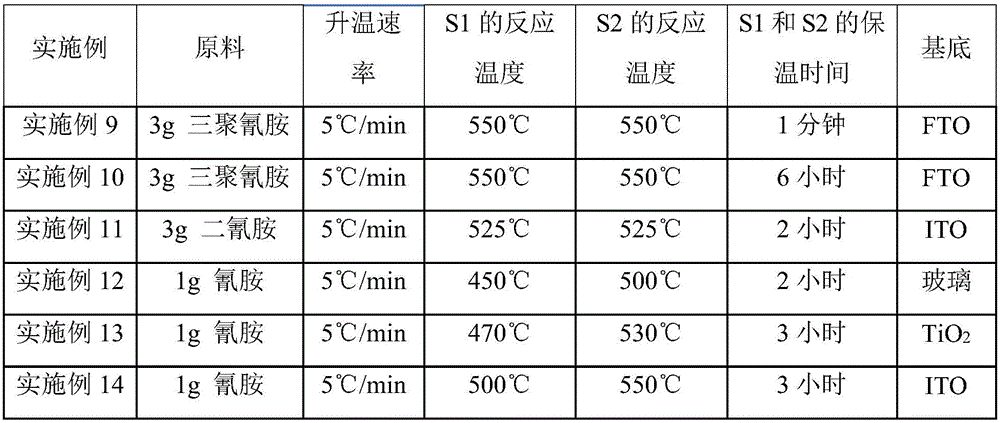

[0024] (1) Under a protective atmosphere, heat nitrogen at 450°C to 550°C (preferably 500°C to 550°C to ensure gasification and deamination of the carbon nitride raw material while preventing excessive decomposition of the formed carbon nitride precursor) Carbonize the raw material for 1 minute to 6 hours, so that the carbon nitride raw material is gasified and attached to the surface of the heat-resistant carrier to form a carbon nitride precursor;

[0025] Wherein, protective atmosphere can be nitrogen, helium, argon or its mixed gas; Carbon nitride raw material is melamine, dicyandiamide, one or more in cyanamide, urea or thiourea, and is preferably melamine, cyanogen amine or dicyandiamide to ensure that the obtained carbon nitride film has good thermoelectric properties.

[0026] The heat-resistant carrier can be graphite...

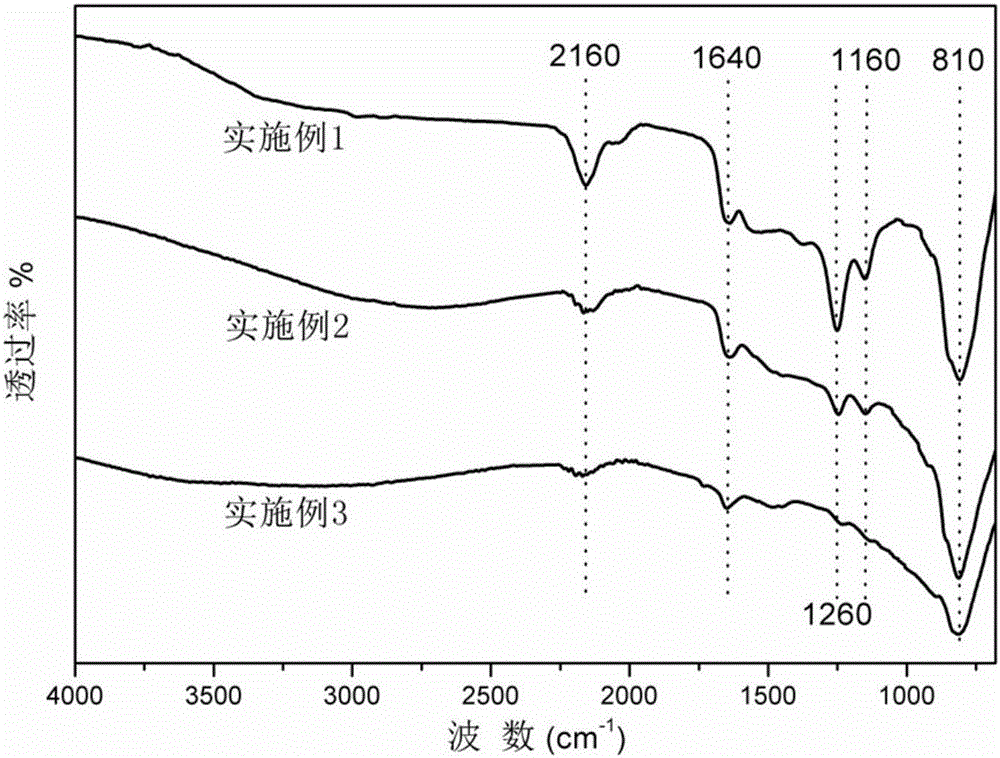

Embodiment 1

[0030] S1. Add 3g of melamine to the crucible, then wrap the crucible and place it in a tube furnace, pretreat it with nitrogen for 20 minutes, and raise the temperature to 550°C at a heating rate of 2°C / min under nitrogen atmosphere, and keep it warm 4 hours, then lowered to room temperature to complete the first heat treatment to obtain a carbon nitride precursor with a thickness of about 1.3mm, and deposited on the crucible;

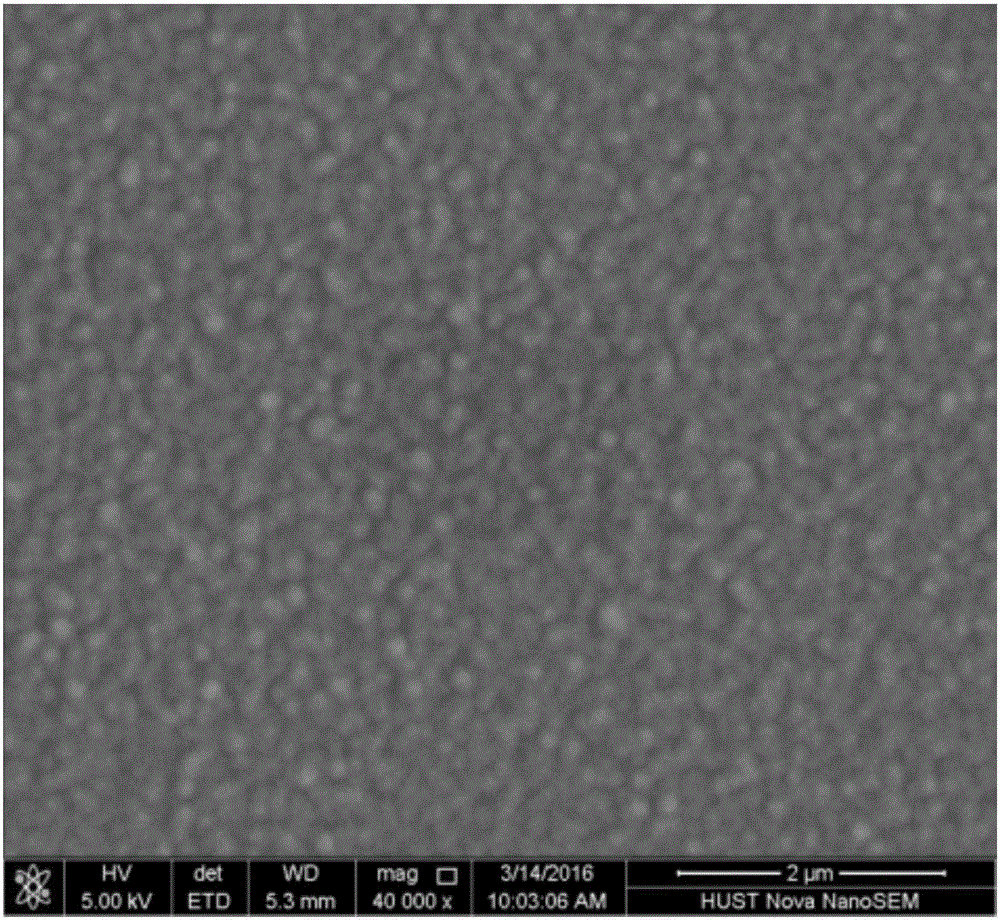

[0031] S2. Use fluorine-doped tin oxide (FTO) as the substrate, put it under the crucible deposited with carbon nitride after the first heat treatment, then wrap it in a tube furnace, and pre-treat it with nitrogen gas; under nitrogen atmosphere, With a heating rate of 2°C / min, the temperature was raised to 550°C, kept for 4 hours, and then lowered to room temperature to complete the second heat treatment; a yellow film with a thickness of about 150 nm on the FTO was formed as a carbon nitride film.

Embodiment 2

[0033] S1. Add 3g of dicyandiamide to the crucible, then wrap the crucible and place it in a tube furnace, pretreat with nitrogen for 20 minutes, and raise the temperature to 500°C at a heating rate of 5°C / min under nitrogen atmosphere , keep warm for 2 hours, then lower to room temperature to complete the first heat treatment, obtain a carbon nitride precursor with a thickness of about 1.4mm, and deposit it on the crucible;

[0034] S2. Use FTO as the substrate, put it under the crucible with carbon nitride deposited after the first heat treatment, then wrap it in a tube furnace, and pre-treat it with nitrogen gas; under nitrogen atmosphere, at a heating rate of 5°C / min , raise the temperature to 500°C, keep it warm for 2 hours, and then lower it to room temperature to complete the second heat treatment; a yellow film is formed on the FTO, which is a graphitic carbon nitride film with a thickness of about 150nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Seeback coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com