Synthetic method of polyether ester block copolymer

A technology of block copolymers and synthesis methods, which is applied in the field of synthesis of polyether ester block copolymers, can solve the problems of large dosage, many side reactions, and unstable production products, so as to achieve stable production products and improve the efficiency of esterification. Reaction rate, effect of increasing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

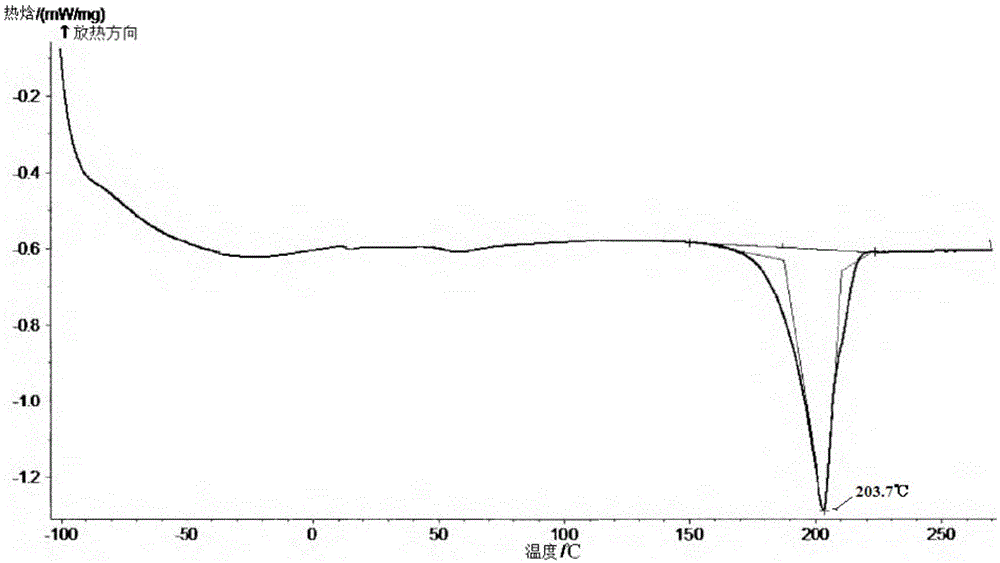

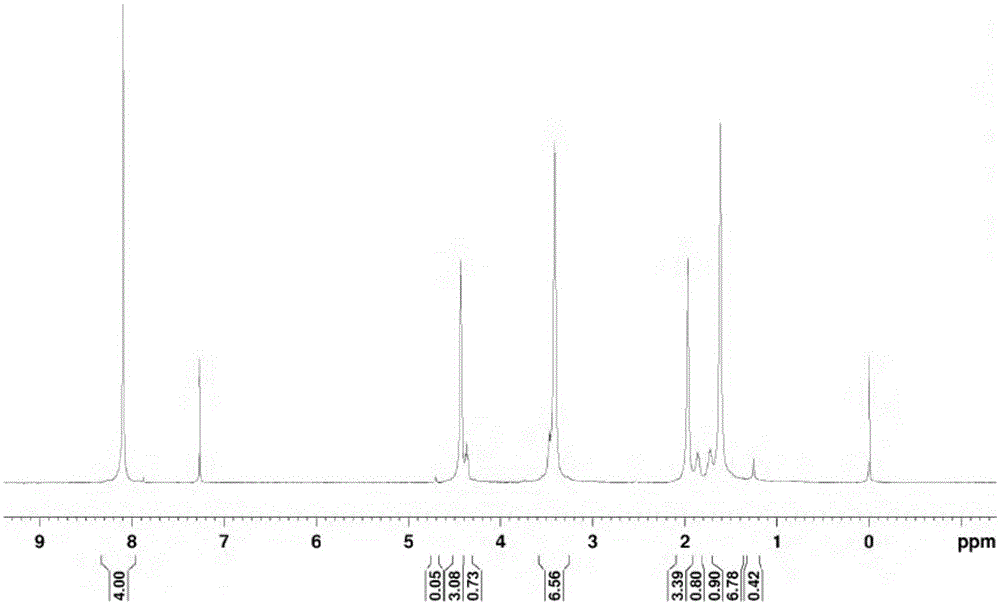

Embodiment 1

[0054] Add PTA: 996g, BD: 972ml, tetrahydrofuran polyether (PTMG, molecular weight: 1000) 664g, antimony acetate 0.35g, magnesium acetate 0.2g, sodium acetate 0.2g into the reaction kettle, then open the reaction kettle to stir and heat, PTA and BD The molar ratio is 1:1.8, and the mass ratio of PTA to PTMG is 60:40. When the temperature in the kettle (that is, the internal temperature) reaches 130°C, add 0.55ml of tetrabutyl titanate and continue to heat up to 210°C to start the esterification reaction and The esterification starts to effluent, the esterification reaction is normal pressure reaction, the internal temperature is controlled between 210-250°C, the water temperature at the top of the fractionation column is about 100°C, and the esterification reaction is ended when the temperature at the top of the fractionation column naturally drops to 85°C ( At this time, the reaction water is relatively slow, which proves that the esterification reaction is close to the end), ...

Embodiment 2

[0060] Add PTA: 996g, BD: 810ml, tetrahydrofuran polyether (PTMG, molecular weight: 1000) 664g, antimony acetate 0.35g, magnesium acetate 0.2g, sodium acetate 0.2g into the reaction kettle, then start the reaction kettle to stir and heat, the PTA and BD The molar ratio is 1:1.5, and the mass ratio of PTA to PTMG is 60:40. When the temperature in the kettle reaches 130°C, add 0.55ml of tetrabutyl titanate and continue to raise the temperature to 210°C to start the esterification reaction and start esterification to effluent. The esterification reaction is a normal pressure reaction, the internal temperature is controlled between 210 and 250°C, and the temperature of the outlet water at the top of the fractionation column is about 100°C. Slowly proves that the esterification reaction is close to the end), the esterification time is 75 minutes, and the esterification effluent is 220ml. After adding 0.55ml of tetrabutyl titanate into the obtained esterification reactant, it starts ...

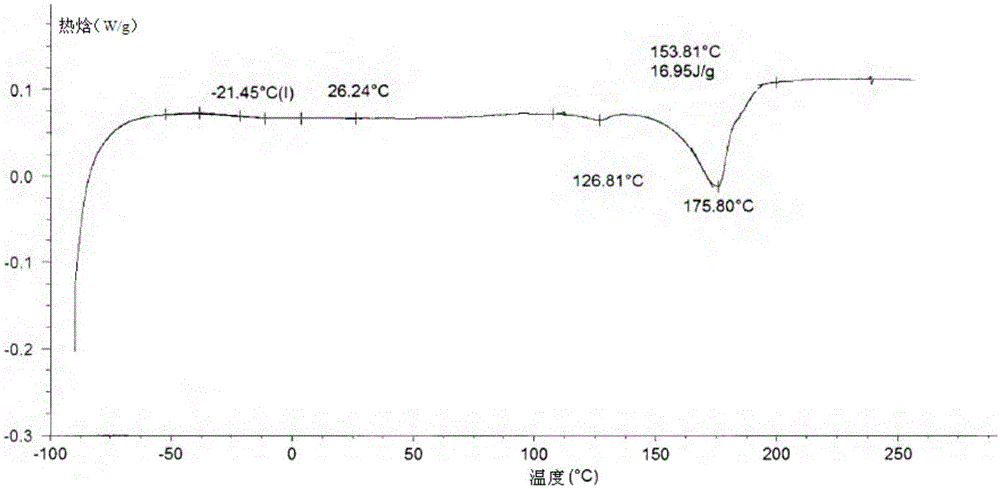

Embodiment 3

[0062] Add PTA: 996g, BD: 918ml, tetrahydrofuran polyether (PTMG, molecular weight: 1000) 815g, antimony acetate 0.35g, magnesium acetate 0.2g, sodium acetate 0.2g in the reaction kettle, then open the reaction kettle to stir and heat, the PTA and BD The molar ratio is 1:1.7, and the mass ratio of PTA to PTMG is 55:45. When the temperature in the kettle reaches 130°C, add 0.55ml of tetrabutyl titanate and continue to raise the temperature to 210°C to start the esterification reaction and start esterification to effluent. The esterification reaction is a normal pressure reaction, the internal temperature is controlled between 210 and 250°C, and the temperature of the outlet water at the top of the fractionation column is about 100°C. Slowly proves that the esterification reaction is close to the end), the esterification time is 1.5 hours, and the esterification effluent is 260ml. After adding 0.55ml of tetrabutyl titanate into the obtained esterification reactant, it begins to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com