Method and equipment for preparing electronic grade gas by adopting thermal coupling technology

A heat-coupled, electronic-level technology, applied in the chemical industry, can solve the problems of leakage safety accidents, fluorine gas is highly toxic, highly chemically active, and strong oxidizing, and achieves simple processes, significant economic and energy-saving benefits, and reduced equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

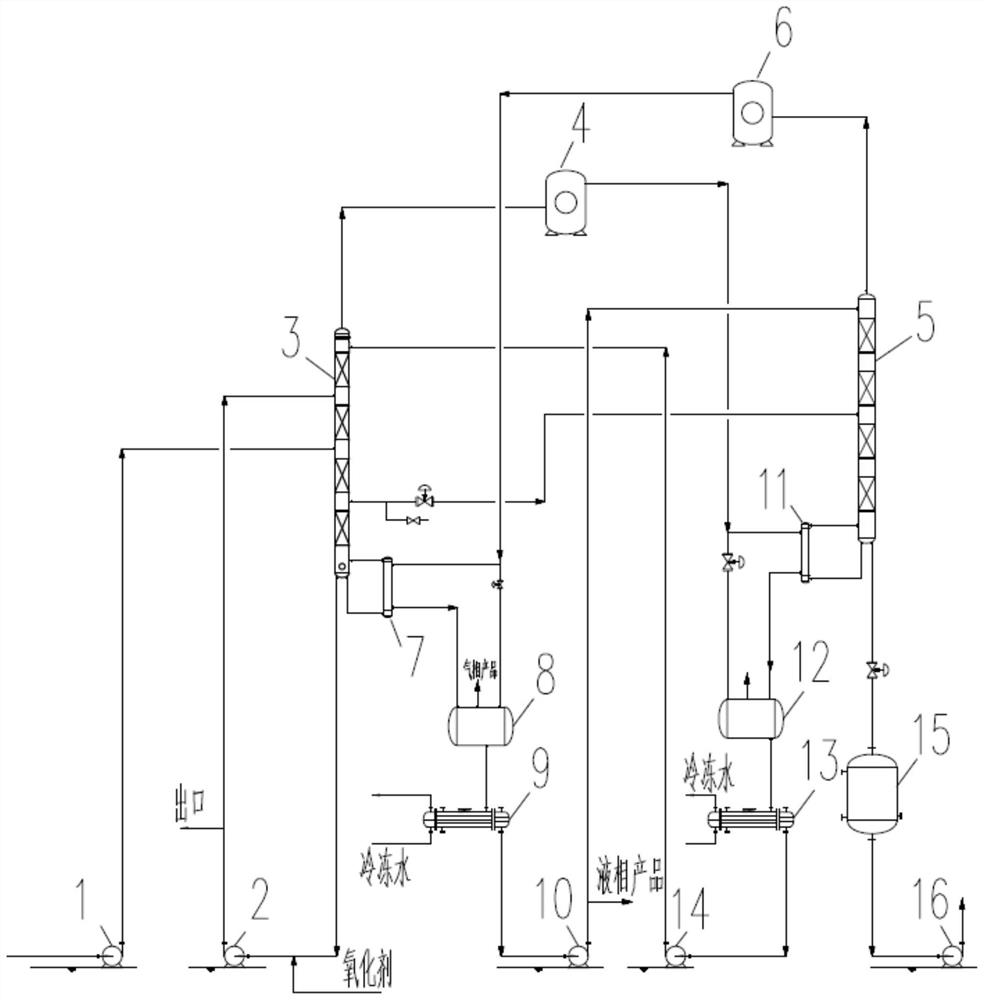

[0058] like figure 1 As shown, a device for preparing electronic-grade gas using a double-tower pressurized heat pump thermal coupling technology includes a reactive rectification thermal coupling tower 3, a rectification thermal coupling tower 5, and the reactive rectification thermal coupling tower 3 tower bottom is equipped with a first The thermally coupled reboiler 7 is equipped with a second thermally coupled reboiler 11 at the bottom of the rectification thermally coupled tower 5; the raw material inlet of the reactive rectification thermally coupled tower 3 is connected to the raw material conveying pipeline, and the There is a raw material conveying pump 1 on the road, and the discharge port at the bottom of the reactive rectification thermal coupling tower 3 is connected with the circulating inlet on the upper part of the reactive rectification thermal coupling tower 3 through the outer circulating pipeline of the tower, and an oxidant circulating pump 2 is arranged o...

Embodiment 2

[0068] Industrial grade carbon dioxide raw material, the main components are as follows: carbon dioxide 96.9mol%, carbon monoxide 0.403mol%, nitrogen 2.7mol%, SO 2 About 1ppmv, methanol about 2ppmv, water about 0.5ppmv, COS about 0.5ppmv, oxygen 465ppmv, Fe 2+ About 9~10ppmv

[0069] The oxidizing agent adopts 6wt% potassium permanganate solution.

[0070] The theoretical plate number of reactive distillation thermal coupling tower 3 is 45, the raw material inlet is located on the 22nd plate, the side line extraction port is located on the 37th plate, the oxidant feed port (ie the circulation inlet) is located on the 16th plate, and the reflux port is located on the 16th plate. 16 boards.

[0071] The number of theoretical plates of the rectification heat coupling tower is 44, the feed port is located on the 21st board, and the discharge port is located on the last theoretical board.

[0072] Adopt embodiment 1 double tower pressurized heat pump heat coupling process to pre...

Embodiment 3

[0077] Industrial grade arsine raw material, the main components are as follows: hydrogen 2000ppmv, nitrogen 1000ppmv, carbon dioxide 80ppmv, water 1ppmv, the rest are arsine 0.996914mol%, Fe 2+ is 5ppmv.

[0078] The oxidizing agent used 3 wt% potassium dichromate solution.

[0079] The theoretical plate number of the reactive distillation thermal coupling tower 3 is 55, the feed inlet is located on the 14th plate, the side line extraction outlet is located on the 44th plate, and the oxidant feed port is located on the 11th plate.

[0080] The number of theoretical plates of the rectification heat coupling tower 5 is 50, the feed port is located on the 38th plate, and the discharge port is located on the last theoretical plate.

[0081] Adopt embodiment 1 double tower pressurized heat pump heat coupling process to prepare electronic grade arsine, the steps are as follows:

[0082] Industrial grade arsine raw material (in gaseous state, feed temperature 0°C, feed pressure 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com